All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

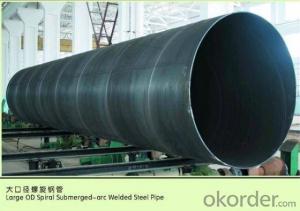

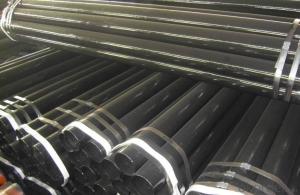

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can welded steel pipes be used for pharmaceutical testing facilities?

Welded steel pipes can be used for pharmaceutical testing facilities, but it is crucial to ensure that the pipes meet the specific requirements and regulations set forth for pharmaceutical applications. This includes factors such as material composition, surface finish, and cleanliness to avoid any contamination risks. Additionally, proper installation and maintenance procedures should be followed to ensure the integrity of the welded steel pipes in such sensitive environments.

Can welded steel pipe be used for structural columns?

Yes, welded steel pipe can be used for structural columns. It has high strength and durability, making it suitable for supporting heavy loads and providing structural stability in various construction applications.

How are welded steel pipes repaired in case of damage?

In case of damage to welded steel pipes, the repair process typically involves cutting out the damaged section and replacing it with a new piece of pipe. This is done by welding the new section into place, ensuring a secure and leak-proof connection. The damaged area may also be repaired using welding techniques such as patching or overlaying, depending on the extent of the damage. It is important to assess the severity of the damage and follow appropriate repair procedures to maintain the structural integrity and functionality of the welded steel pipes.

What are the factors to consider when selecting the appropriate grade of steel for a welded steel pipe?

When selecting the appropriate grade of steel for a welded steel pipe, several factors need to be considered. These factors include the intended application and specific requirements of the pipe, such as the operating temperature and pressure, the type of fluid or gas being transported, and any environmental conditions the pipe may be exposed to. Other factors to consider are the desired mechanical properties, such as strength, toughness, and corrosion resistance, as well as the cost and availability of the chosen grade of steel. Ultimately, the selection should be based on finding a balance between meeting the necessary specifications and ensuring cost-effectiveness and long-term durability of the welded steel pipe.

What is the impact of surface roughness on the flow characteristics of welded steel pipe?

Surface roughness has a significant impact on the flow characteristics of welded steel pipe. Higher surface roughness creates more resistance to fluid flow, resulting in increased pressure drop and reduced flow rate. It also promotes turbulence, leading to energy losses and potential erosion within the pipe. Therefore, minimizing surface roughness through proper surface treatment or finishing is crucial to optimize the flow efficiency and performance of welded steel pipes.

Wholesale Welded Steel Pipe from supplier in Kyrgyzstan

We are a Welded Steel Pipe supplier serving the Kyrgyzstan, mainly engaged in the sale, quotation, and technical support services of various Welded Steel Pipe products in the Kyrgyzstan region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Welded Steel Pipe procurement services in the Kyrgyzstan. Not only do we have a wide range of Welded Steel Pipe products, but after years of market development in the Kyrgyzstan, we can also provide valuable experience for your projects.