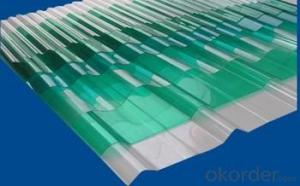

Perspex Corrugated Roofing Sheet

Perspex Corrugated Roofing Sheet Related Searches

Raw Material For Solar Cells Ac Inverter For Solar Panels Plastic Wall Coverings For Bathrooms Fiberglass Sheets For Roofing Heat Reflective Material For Roof Wall Panels For Basement Felt Paper For Roofing Retaining Wall With Geogrid Plastic Coated Steel Roofing Sheets High Quality Roofing FeltHot Searches

Steel Mesh Panels For Sale Cheap High Tea Sets For Sale Cheap Solar Cells For Sale Q Cells Solar Panels For Sale Used Foam Board Insulation For Sale Welded Wire Panels For Sale Types Of Temporary Side Panels For Cement Deck Fiberglass Panels For Sale Magnesium Oxide Board For Sale Hdf Board For Sale sintra board for sale Cheap Mini Laptops For Sale Plywood For Sale Cheap Sandwich Panels For Sale resin panels for sale Cheap Washers For Sale Cheap Tall Vases For Sale Eps Panels For Sale Air Conditioner For Cheap Prices Gypsum Board Price Per Sheet In IndiaPerspex Corrugated Roofing Sheet Supplier & Manufacturer from China

Okorder.com is a professional Perspex Corrugated Roofing Sheet supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Perspex Corrugated Roofing Sheet firm in China.Hot Products

FAQ

- Steel coils are processed for cutting to length or blanking through a series of steps. First, the coil is uncoiled and flattened to remove any inherent deformities. Then, the edges are trimmed to ensure uniform width and straightness. Next, the coil is fed into a leveling machine to eliminate any remaining inconsistencies in thickness. Once leveled, the steel is conveyed to a cutting machine where it is precisely cut into individual sheets of desired length or blanks. These sheets or blanks are then stacked and prepared for further fabrication or distribution.

- Steel coils are used in the production of steel wire by being uncoiled and fed into a wire drawing machine. The steel wire is then drawn through a series of dies to reduce its diameter and increase its length. The coils provide a continuous and consistent supply of steel, ensuring a smooth and efficient production process.

- Steel coils contribute to seismic resistance in structures by providing strength and flexibility. When placed strategically within the structure, steel coils can absorb and dissipate the energy generated during an earthquake, reducing the impact on the overall structure. This makes the structure more resistant to seismic forces, preventing or minimizing damage that could occur during an earthquake.

- To create smaller, more manageable coils, the recoiling of steel coils entails either rewinding or unrolling large steel coils. This operation is typically carried out in steel processing plants or coil service centers. The initial step in the recoiling process involves identifying the appropriate coil for recoiling. Factors such as coil size, weight, and quality are taken into consideration when making this selection. Once the coil has been chosen, it is placed onto a recoiling machine, which is equipped with various mechanisms to facilitate the recoiling process. The recoiling machine consists of a mandrel or drum, around which the coil is wound or unwound. To ensure stability during the recoiling process, the coil is securely fastened onto the mandrel using either mechanical clamps or hydraulic pressure. In the case of rewinding or recoiling a large coil into smaller coils, the machine initiates the process by unwinding the original coil. This is achieved by rotating the mandrel in the opposite direction, causing the coil to gradually unroll. As the coil unwinds, it passes through various straightening and flattening mechanisms, which help ensure that the coils are produced with consistent dimensions and quality. Once the original coil has been completely unwound, the machine commences the rewinding process. The smaller coils are formed by winding the steel strip onto the mandrel in a controlled manner. The speed and tension of the rewinding process are carefully regulated to prevent any damage to the steel strip. Throughout the recoiling process, various quality control measures are implemented to ensure that the produced coils meet the desired specifications. These measures may include monitoring the thickness, width, and surface quality of the steel strip, as well as conducting periodic inspections to identify any defects or irregularities. Upon completion of the rewinding process, the smaller coils are typically removed from the mandrel and prepared for further processing or shipment. This may involve applying protective coatings, labeling, or packaging the coils, depending on their intended use. In conclusion, the recoiling of steel coils involves unwinding large coils, straightening and flattening the steel strip, and rewinding it onto a mandrel to create smaller, more manageable coils. This operation requires specialized machinery and meticulous control to ensure the quality and consistency of the recoiled coils.

- Is the product of mild steel environmentally friendly? does it produce any emissions?The same question for leather aswell.

- Steel just rusts, it doesn't produce any emissions just sitting there. They even make architectural steel called Corten to rust to a nice patina. If you consider how the steel was made in the first place, a great big NO! Steel making requires massive amounts of electricity plus it gives off some nasty fumes in the liquid state. Leather itself doesn't emit much of anything, but the dyes might. Again though, if you look at how it's made, tanning leather is right up there with steel mills and paper mills for pollution, some of the worst.

- Bronze came before steel, right? thanks

- Yes, bronze was created a long time before steel. Steel came a long time after iron too.

- Steel coils are coated to prevent rust and corrosion through a process called galvanization, wherein a layer of zinc is applied to the surface. This zinc layer acts as a sacrificial barrier, protecting the steel from exposure to moisture and oxygen, thereby preventing rust and corrosion.

- Steel coils are inspected for width variations using specialized equipment such as laser or optical sensors that measure the width of the coils at regular intervals. These sensors provide accurate and precise measurements, allowing inspectors to identify any variations in width across the length of the coil.