Ms Heavy Steel Rail 50Mn, U71Mn

- Loading Port:

- Qingdao Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 1000000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specificaions of Ms Heavy Steel Rail 50Mn, U71Mn

Production Standard: GB2585-81

Material: 50Mn, U71Mn

Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| |

50Mn |

0.48—0.56 |

0.70—1.00 |

≤0.035 |

≤0.035

|

0.17-0.37 |

U71Mn | 0.65—0.76 | 1.10—1.40 | ≤0.030 | ≤0.030 | 0.15-0.35 |

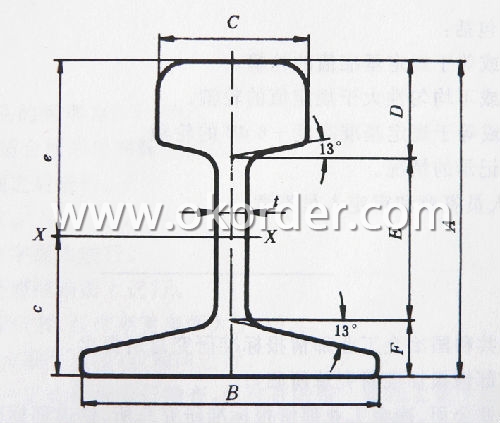

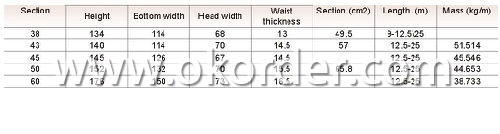

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Length: 10m, 12m, 12.5m or as the requriement of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usage & Applications of Ms Heavy Steel Rail 50Mn, U71Mn

Heavy Steel Rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel, can also be used for tower crane and other crane track.

For example: railway, subway, transportation track, express, curve way, tunnel way.

Packaging & Delivery of Ms Heavy Steel Rai 50Mn, U71Mn

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Ms Heavy Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Ms Heavy Steel Rail 50Mn, U71Mn

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Ms Heavy Steel Rail 50Mn, U71Mn

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q:What is a rail pile?

- The rail as a "pile", through the piling machine, pile hammer or other means to sink into the soil, from the lateral support of the soil or vertical bearing role, that is, rail pile. The strength of the rail is two or three times that of the ordinary Q235 steel, and the price is high, but the bending modulus is much smaller than that of the I-beam, so it is not worthwhile to consider it from the cost point of view. Steel rails are usually used only when existing old rails are used as temporary structures or for emergency purposes.

- Q:What are the specifications for steel rail dimensions?

- The specifications for steel rail dimensions can vary depending on the specific application and country. However, there are general standards and specifications that are commonly used in the industry. In terms of length, steel rails are typically manufactured in standard lengths that can range from 10 to 30 meters. The exact length can vary depending on the specific requirements of the railway system or project. The weight of steel rails is an important factor as it affects the strength and durability of the tracks. Common steel rail weights range from 30 to 100 kilograms per meter. Again, the exact weight can depend on the specific application and requirements. The height or depth of the rail, also known as the railhead, is another important dimension. The railhead height can typically range from 100 to 160 millimeters, with the specific height depending on the rail profile and design. The width or base of the rail, known as the railfoot, is another crucial dimension. The railfoot width can range from 50 to 75 millimeters, again depending on the rail profile and design. Furthermore, the shape or profile of the rail is also important. There are various rail profiles available, such as flat-bottomed rails, bullhead rails, and vignole rails. Each profile has its own specifications and dimensions, including the height, width, and angles of the railhead and railfoot. It is worth noting that these specifications can vary between different countries and railway systems. For example, the American Railway Engineering and Maintenance-of-Way Association (AREMA) has its own set of standards and specifications for steel rail dimensions, which may differ from those used in Europe or other regions. In summary, the specifications for steel rail dimensions include the length, weight, railhead height, railfoot width, and rail profile. These specifications can vary depending on the specific application, country, and industry standards.

- Q:What are the different types of rail sleepers used with steel rails?

- There exist various rail sleepers utilized alongside steel rails, each possessing unique characteristics and advantages. 1. Wooden Sleepers: Known as timber sleepers, wooden sleepers have enjoyed widespread usage in rail construction for numerous years. Crafted from treated hardwood or softwood, they offer commendable insulation and resistance to decay. Wooden sleepers are relatively cost-effective and simple to install, making them a favored option in many railway systems. 2. Concrete Sleepers: Also referred to as concrete ties, concrete sleepers represent another commonly employed type of sleeper. Created from pre-stressed concrete, they boast exceptional durability and long-lasting performance. Although pricier than wooden sleepers, concrete sleepers provide heightened stability and load-bearing capacity, rendering them suitable for high-speed and heavy traffic railways. 3. Steel Sleepers: Sometimes called steel ties, steel sleepers consist entirely of steel. They possess incredible strength and durability, capable of withstanding heavy loads and high-speed train operations. Steel sleepers are often utilized in regions with extreme weather conditions or concerns about vandalism, as they resist rot, fire, and theft. 4. Composite Sleepers: Also known as plastic sleepers or synthetic sleepers, composite sleepers represent a more recent advancement in rail sleeper technology. Comprising a blend of plastic materials, such as recycled plastics or fiberglass, they offer a lightweight and environmentally friendly substitute for traditional sleepers. Composite sleepers provide commendable insulation, corrosion resistance, and low maintenance requirements. 5. Prestressed Concrete Sleepers: Prestressed concrete sleepers represent a specialized variation of concrete sleepers that incorporate steel wires or rods within the concrete structure. These steel reinforcements enhance the sleeper's strength and flexibility, minimizing the risk of cracking or deformation under heavy loads. Prestressed concrete sleepers are commonly employed in high-speed railways and regions with challenging terrain. Each type of rail sleeper possesses its own set of advantages and disadvantages. The choice of sleeper will depend on factors such as the requirements of the railway system, budget constraints, and environmental conditions.

- Q:Can steel rails be used in railway track monitoring systems?

- Yes, steel rails can be used in railway track monitoring systems. Steel rails are commonly used in railway tracks due to their high strength and durability. They provide a stable surface for trains to run on and can also be equipped with various monitoring sensors to collect data on track conditions, such as vibrations, temperature, and stress. This data can then be used to detect and prevent potential track faults, ensuring safe and efficient railway operations.

- Q:How are steel rails protected against vandalism or sabotage?

- Steel rails are protected against vandalism or sabotage through various measures such as regular inspections, surveillance systems, security patrols, and public awareness campaigns. Additionally, access to rail tracks is restricted and monitored, and any suspicious activity is reported to the authorities immediately.

- Q:How are steel rails affected by ground settlement or shifting?

- Steel rails are significantly affected by ground settlement or shifting. Ground settlement refers to the process by which the ground beneath the steel rails sinks or collapses, while ground shifting refers to the lateral movement of the ground. Both of these phenomena can have detrimental effects on the stability and integrity of steel rails. When ground settlement occurs, the level of the ground beneath the rails becomes uneven. This unevenness can create stress concentrations on the rails, leading to increased wear and tear. The settlement may cause the rails to become misaligned, resulting in a rough and bumpy ride for trains. Additionally, ground settlement can also lead to the formation of voids or depressions beneath the rails, which can further compromise their stability. Ground shifting, on the other hand, can cause lateral movement of the ground beneath the steel rails. This movement can result in the misalignment of the rails, leading to derailment risks. The lateral forces exerted by shifting ground can also cause the rails to buckle, resulting in significant damage and disruption to the railway system. To mitigate the impact of ground settlement or shifting on steel rails, various measures can be taken. These include monitoring the ground conditions regularly, implementing proper drainage systems to prevent water accumulation, and stabilizing the ground using techniques such as soil reinforcement or ground improvement methods. Proper maintenance and inspection of the rails are also crucial to detect any signs of settlement or shifting early on and take appropriate corrective actions. In conclusion, ground settlement or shifting can have significant adverse effects on steel rails. It is essential to monitor and address these issues promptly to ensure the safety and efficiency of railway systems.

- Q:How do steel rails contribute to train braking performance?

- Steel rails contribute to train braking performance in several ways. Firstly, steel rails provide a smooth and stable surface for the train wheels to grip onto during braking, allowing for effective traction and preventing wheel slippage. This ensures that the train can decelerate efficiently and come to a stop in a shorter distance. Additionally, the hardness and durability of steel rails allow for consistent and reliable braking performance over long periods of time, minimizing maintenance needs. Overall, steel rails play a crucial role in maximizing the braking efficiency and safety of trains.

- Q:Are steel rails suitable for heavy freight trains?

- Yes, steel rails are highly suitable for heavy freight trains. Steel rails have excellent strength, durability, and load-bearing capacity, making them ideal for supporting the weight and pressure exerted by heavy freight trains. Additionally, steel rails offer better resistance to wear, deformation, and fatigue, ensuring safe and efficient operation of heavy freight trains over long distances.

- Q:How are steel rails protected against ultraviolet radiation?

- Steel rails are typically protected against ultraviolet radiation by applying a protective coating, such as a paint or a specialized weather-resistant finish. This coating acts as a barrier to prevent the harmful effects of UV radiation on the steel, ensuring its durability and longevity.

- Q:What are the different fastening systems used for steel rails?

- There are several different fastening systems used for steel rails, including the use of dog spikes, screw spikes, elastic rail clips, and pandrol clips. These systems are designed to securely fasten the steel rails to the sleepers or ties, ensuring stability and safety for railway tracks.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ms Heavy Steel Rail 50Mn, U71Mn

- Loading Port:

- Qingdao Port,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 1000000MT/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords