Steel Fiber Copper Coated From Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

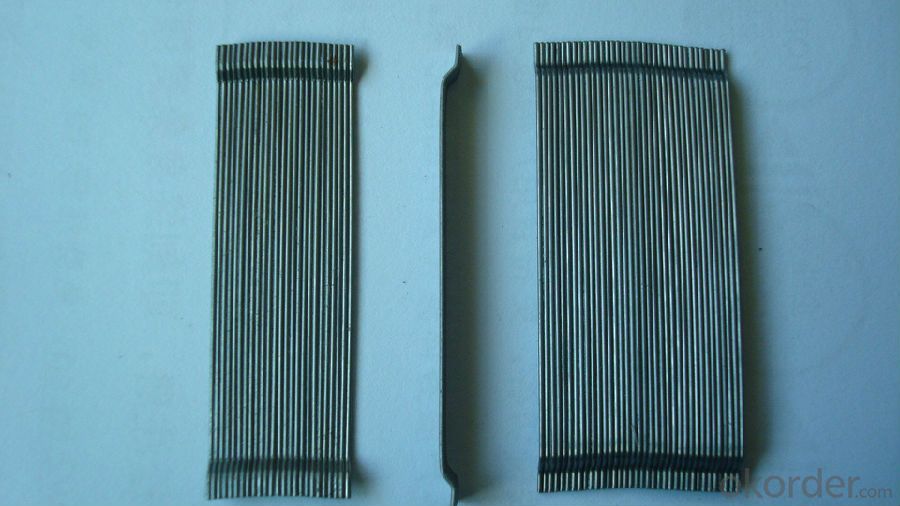

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Such steel fiber using the technology into a row of single steel fiber bonding with water-soluble glue, to ensure that the steel fiber uniformly dispersed in concret, easily stirred, eliminate agglomerate phenomena such as, due to the bonding of steel fiberrows technology, steel fibers in concrete can be evenly distributed, so that the concrete structure by the impact of steel fibers can absorb impact energy, reduce stress concentration, effectively control the emergence and development of cracks in the concrete, to extend the structural life.

As reliable and efficient concrete reinforcement material, it is widely uesd in buildings, bridges, thin roof engineering, highway etc.

In bonding steel fiber concrete internal steel fiber, as long as ramming close-grained, and air separation, steel fiber generally don't happen corrosion phenomena. Dew in the concrete surface or in the crack width more than 0.25 mm, jumper cracks in the steel fiber, vulnerable to corrosion phenomena.

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q:What is the effect of melt extract stainless steel fiber on the creep behavior of concrete?

- Melt extract stainless steel fiber has a positive effect on the creep behavior of concrete. The addition of these fibers helps to reduce the amount of creep deformation, thus improving the overall strength and durability of the concrete. The fibers enhance the tensile strength of the concrete, limiting cracking and preventing long-term deformation under sustained loads. Consequently, the presence of melt extract stainless steel fibers can significantly increase the creep resistance of concrete structures.

- Q:How does melt extract stainless steel fiber affect the curing time of concrete?

- The curing time of concrete can be influenced both positively and negatively by the use of melt extract stainless steel fiber. Incorporating stainless steel fibers into concrete can enhance its early age strength development, resulting in a quicker curing process. These fibers act as reinforcement, improving the overall mechanical properties of the concrete and reducing drying shrinkage. Additionally, stainless steel fibers can enhance the durability and resistance to cracks in concrete, leading to a faster curing time. By preventing cracks and reducing the need for repairs or maintenance, the concrete can cure more efficiently. However, the addition of stainless steel fibers can also lengthen the curing time of concrete. This is because the fibers may impede the movement of water within the concrete mixture, slowing down the hydration process. Moreover, the presence of fibers can increase the viscosity of the concrete, making it more challenging for moisture to penetrate and fully hydrate the cement particles. Ultimately, the impact of melt extract stainless steel fiber on the curing time of concrete relies on various factors like the amount of fiber used, aspect ratio, and mix design. It is crucial to carefully consider these factors and conduct thorough testing to determine the optimal dosage and type of fiber to achieve the desired curing time in concrete applications.

- Q:Can melt extract stainless steel fiber be used in retaining walls?

- Retaining walls can indeed utilize melt extract stainless steel fiber. In numerous construction scenarios, including retaining walls, stainless steel fiber serves as a prevalent reinforcement material. It boasts exceptional tensile strength, corrosion resistance, and durability, rendering it ideal for withstanding the pressures and forces confronting retaining walls. By incorporating stainless steel fiber into the concrete mixture, the overall structural integrity of the retaining wall can be enhanced, reducing the likelihood of cracking and enhancing its long-term performance. As a result, melt extract stainless steel fiber presents itself as a fitting choice for reinforcing retaining walls.

- Q:Can melt extract stainless steel fiber reduce the risk of spalling in high-strength concrete?

- Yes, melt extract stainless steel fiber can reduce the risk of spalling in high-strength concrete. Stainless steel fibers improve the tensile strength, ductility, and overall durability of concrete. When added to high-strength concrete, these fibers help to control cracking and minimize the potential for spalling, especially under severe loading conditions or in high-temperature environments.

- Q:How does melt extract stainless steel fiber affect the shrinkage cracking in concrete overlays?

- Melt extract stainless steel fiber can significantly reduce shrinkage cracking in concrete overlays. The addition of these fibers helps to distribute and absorb the tensile stress caused by shrinkage, preventing the formation of cracks. The fibers act as reinforcement, enhancing the overall durability and performance of the concrete overlay.

- Q:What are the different quality standards and certifications for melt extract stainless steel fiber?

- Melt extract stainless steel fiber must adhere to various quality standards and certifications to ensure its performance and quality. Here are some of the most common ones: 1. ISO 9001: This international standard guarantees that the manufacturer has a consistently effective quality management system that meets customer requirements and regulatory obligations. 2. ASTM International: Globally recognized for setting standards, ASTM International has developed specific standards for stainless steel fibers. For instance, ASTM A820 focuses on steel fibers for fiber-reinforced concrete, while ASTM A1094 deals with steel fibers for concrete reinforcement. 3. EN Eurocodes: The Eurocodes are a collection of European standards for structural design. EN 14889-1 is the specific European standard for steel fibers used in concrete reinforcement, outlining requirements for mechanical properties, dimensions, and durability. 4. AISI: The American Iron and Steel Institute (AISI), representing North American steel producers, has established AISI 304 or AISI 316 as specifications for stainless steel fibers. These specifications cover chemical composition, mechanical properties, and other fiber characteristics. 5. CE Marking: CE marking is compulsory for certain products sold in the European Economic Area (EEA). It signifies compliance with essential health, safety, and environmental requirements specified in European Union directives. 6. ICC-ES: The International Code Council Evaluation Service (ICC-ES) offers evaluation reports and certifications for building products. Their evaluation criteria ensure that steel fibers employed in concrete reinforcement meet specific safety and performance requirements. It is essential to consider that the applicable quality standards and certifications for melt extract stainless steel fiber may vary depending on its intended application. Consulting the manufacturer or supplier is recommended to determine the relevant standards and certifications for a particular product.

- Q:Can melt extract stainless steel fiber be used in elevated slabs?

- Yes, melt extract stainless steel fiber can be used in elevated slabs. Melt extract stainless steel fibers are known for their high tensile strength, excellent corrosion resistance, and durability. These properties make them suitable for use in various concrete applications, including elevated slabs. When used in elevated slabs, melt extract stainless steel fibers help enhance the overall strength and performance of the concrete. They provide additional reinforcement and improve crack resistance, which is especially important in structures subjected to high loads and potential cracking, such as elevated slabs. Moreover, melt extract stainless steel fibers can help control shrinkage and reduce the risk of cracking caused by drying shrinkage in elevated slabs. They act as a reinforcement throughout the concrete matrix, limiting crack propagation and minimizing the likelihood of structural damage. Additionally, melt extract stainless steel fibers offer excellent resistance to corrosion, ensuring the long-term durability of the elevated slab. This is particularly important in environments where the slab is exposed to moisture or chemical substances that could potentially corrode the steel reinforcement. Overall, melt extract stainless steel fibers can be a valuable addition to elevated slabs, providing enhanced strength, crack resistance, and durability. However, it is essential to consult with a structural engineer or construction professional to ensure proper dosage and installation techniques for the specific project requirements.

- Q:Can melt extract stainless steel fiber be used in the construction of wastewater treatment plants?

- Indeed, the utilization of melt extract stainless steel fiber is feasible in the development of wastewater treatment plants. Due to its exceptional resistance to corrosion, stainless steel fiber is well-suited for deployment in settings characterized by elevated humidity levels and chemical exposure, like wastewater treatment plants. Its application within the facility is diverse and includes reinforcing concrete structures, thereby enhancing their resilience and endurance. The longevity of the stainless steel fiber is guaranteed by its resistance to corrosion, which diminishes the likelihood of deterioration over time. Furthermore, the fiber's remarkable tensile strength and capacity to endure extreme temperatures make it a dependable option for employment in wastewater treatment plants.

- Q:Is melt extract stainless steel fiber compatible with different types of cement?

- Melt extract stainless steel fiber is indeed compatible with various types of cement. It proves suitable for both Portland cement and other varieties like slag cement, fly ash cement, or blended cements. By incorporating these stainless steel fibers into the cement mixture, one can effectively bolster its performance and bolster its durability. These fibers actively manage cracking and offer reinforcement to the cement matrix, leading to heightened tensile strength, impact resistance, and fatigue resistance. As a result, melt extract stainless steel fiber emerges as an adaptable material that can elevate the qualities and performance of diverse cement types.

- Q:Does melt extract stainless steel fiber improve the impact resistance of concrete?

- Yes, melt extract stainless steel fiber does improve the impact resistance of concrete.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Fiber Copper Coated From Company CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords