Melt Extract Stainless Steel Fiber 310

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

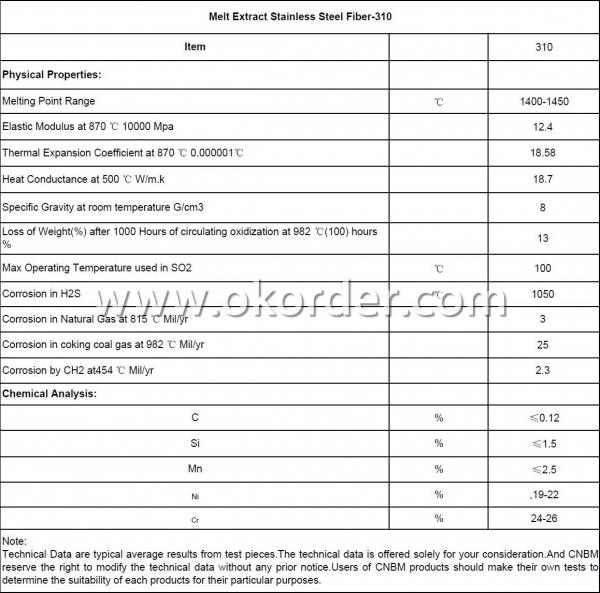

General Information of Melt Extract Stainless Steel Fiber 310

CMAX melt extract stainless steel fiber 310 is produced by melting elements in a crucible packing by paper boxes. A flywheel is then introduced to the crucible and droplets of molten metal are spun into the open air and hardened. CMAX melt extract stainless steel fibers are spun directly from the melt using the company's advanced Melt Extraction (ME) and Melt Overflow (MO) processes. CMAX melt extract stainless steel fiber can increase the lifetime of refractory materials and industrial furnaces by several times, decreasing cost and saving labor costs.

CMAX Melt Extract Stainless Steel Fiber 310 exhibits the following characteristics:

Improve refractories’ performance

Improve refractories’ longevity

Improve refractories’ durability

Significantly reducing downtime and maintance cost

CMAX Melt Extract Stainless Steel Fiberis 310 available in a wide variety of application:

CMAX Melt Extract Stainless Steel Fiberis 310 available in a wide variety of application:

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our company has success in its melt extract stainless steel fiberproducts due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiberapplication and would like to assist you in product selection, system design, and installation techniques. Our products of melt extract stainless steel fiber are in good quality and in best price and we are looking forward for your enquiry.

- Q:Can melt extract stainless steel fiber be used in the construction of water treatment facilities?

- Yes, melt extract stainless steel fiber can be used in the construction of water treatment facilities. Stainless steel fibers are known for their high corrosion resistance, durability, and strength, making them suitable for various applications in water treatment facilities. These fibers can be used in concrete structures to enhance their mechanical properties and resistance to cracking, which is crucial in the construction of water treatment plants where exposure to water and chemicals is common. The stainless steel fibers can also help in preventing the formation of cracks due to shrinkage and thermal stresses, ensuring the long-term integrity and performance of the facility. Additionally, the use of stainless steel fibers can improve the overall structural performance, as well as provide enhanced resistance to abrasion and erosion caused by the movement of water and particles within the treatment processes. Therefore, melt extract stainless steel fiber can be a valuable material in the construction of water treatment facilities.

- Q:Can melt extract stainless steel fiber be used in retaining walls?

- Yes, melt extract stainless steel fiber can be used in retaining walls. Stainless steel fiber is commonly used as a reinforcement material in various construction applications, including retaining walls. It offers excellent tensile strength, corrosion resistance, and durability, making it suitable for withstanding the pressures and forces that retaining walls face. The addition of stainless steel fiber to the concrete mix can improve the overall structural integrity of the retaining wall, reducing the risk of cracking and improving its long-term performance. Therefore, melt extract stainless steel fiber is a suitable option for reinforcing retaining walls.

- Q:How does the addition of melt extract stainless steel fiber affect the toughness of concrete?

- The addition of melt extract stainless steel fiber significantly enhances the toughness of concrete. These fibers act as reinforcement within the concrete matrix, increasing its resistance to cracking and improving its overall durability. The stainless steel fibers help to distribute stress and absorb energy, resulting in a more robust and resilient concrete structure.

- Q:How does melt extract stainless steel fiber improve the resistance to spalling in concrete?

- Melt extract stainless steel fiber improves the resistance to spalling in concrete by reinforcing the material and enhancing its overall durability. When added to the concrete mix, the stainless steel fibers disperse uniformly, forming a three-dimensional network throughout the structure. This network acts as a reinforcement, increasing the tensile strength and crack resistance of the concrete. Spalling in concrete occurs when the surface of the material begins to chip, flake, or peel off due to various factors such as freeze-thaw cycles, high temperatures, or chemical exposure. The addition of melt extract stainless steel fibers helps to mitigate these effects by preventing the propagation of cracks and reducing the expansion and contraction of the concrete. The high tensile strength of stainless steel fibers allows them to absorb and distribute stress throughout the concrete, preventing the formation of cracks and minimizing the impact of external forces. Moreover, the corrosion-resistant properties of stainless steel ensure that the fibers remain intact and do not deteriorate over time, ensuring long-term reinforcement. Additionally, the three-dimensional network created by the stainless steel fibers helps to bridge the cracks that may occur in the concrete. This bridging effect prevents the cracks from widening and propagating, thereby reducing the likelihood of spalling. In summary, melt extract stainless steel fiber improves the resistance to spalling in concrete by reinforcing the material, increasing its tensile strength, reducing crack propagation, and enhancing its overall durability. By adding these fibers to the concrete mix, the risk of spalling due to factors such as freeze-thaw cycles, high temperatures, or chemical exposure is significantly minimized, resulting in a more resilient and long-lasting concrete structure.

- Q:Can melt extract stainless steel fiber be used in tunneling and mining applications?

- Yes, melt extract stainless steel fiber can be used in tunneling and mining applications. This type of fiber is known for its high strength, durability, and resistance to corrosion, which makes it suitable for demanding environments such as tunnels and mines. It can be used to reinforce concrete structures, shotcrete, and other construction materials, providing additional strength and improving their resistance to cracking and deterioration. The stainless steel fiber can also enhance the overall stability and safety of the tunnel or mine by reducing the risk of structural failure or collapse. Additionally, it can withstand high temperatures, fire, and abrasive materials, making it a reliable choice for these applications. Overall, melt extract stainless steel fiber is a valuable material that can effectively enhance the performance and longevity of tunneling and mining projects.

- Q:What are the properties of melt extract stainless steel fiber?

- Melt extract stainless steel fiber has several key properties that make it a highly desirable material in various applications. Firstly, it possesses excellent resistance to high temperatures, making it suitable for use in extreme heat environments. This property allows the stainless steel fiber to maintain its structural integrity and performance even under intense heat conditions. Secondly, melt extract stainless steel fiber exhibits high tensile strength, making it incredibly durable and resistant to breakage or deformation. This property is crucial in applications where the fiber may be subjected to high levels of stress or strain. Additionally, melt extract stainless steel fiber has exceptional corrosion resistance, thanks to its chromium content. This property ensures that the fiber remains resistant to rust, oxidation, and other forms of chemical degradation. Consequently, the stainless steel fiber can be used in harsh environments, including marine or industrial settings where exposure to corrosive substances is common. Another important property of melt extract stainless steel fiber is its electrical conductivity. Due to its metallic nature, the fiber allows for the efficient transfer of electrical currents. This makes it valuable in applications that require electrical grounding or electromagnetic shielding. Moreover, melt extract stainless steel fiber is highly versatile and can be easily incorporated into various materials and structures. It can be blended with concrete, polymers, or other materials to enhance their mechanical properties, such as flexural strength, impact resistance, and crack resistance. This versatility makes it suitable for a wide range of industries, including construction, aerospace, automotive, and textile. In summary, melt extract stainless steel fiber possesses properties such as high temperature resistance, high tensile strength, corrosion resistance, electrical conductivity, and versatility. These properties contribute to its widespread use in diverse applications where strength, durability, and performance under challenging conditions are essential.

- Q:What is the effect of melt extract stainless steel fiber on the thermal conductivity of concrete?

- The inclusion of melt extract stainless steel fiber in concrete tends to enhance its thermal conductivity. The fibers act as heat conductors within the concrete matrix, facilitating the transfer of heat throughout the material. This results in improved thermal conductivity and better heat distribution within the concrete structure.

- Q:Does melt extract stainless steel fiber improve the resistance to spalling of concrete?

- Yes, melt extract stainless steel fiber does improve the resistance to spalling of concrete. Spalling is the phenomenon where the surface layer of concrete flakes or chips off due to various factors such as freeze-thaw cycles, high temperatures, or chemical attacks. By adding melt extract stainless steel fibers to the concrete mix, the fibers act as reinforcement, providing an additional layer of strength and preventing the concrete from spalling. The stainless steel fibers are dispersed throughout the concrete matrix and enhance its overall tensile strength. When the concrete undergoes stress, such as during freeze-thaw cycles or high temperatures, the fibers help to distribute the forces and prevent cracks from propagating. This reinforcement mechanism significantly reduces the chances of spalling, as the stainless steel fibers act as a barrier to prevent the surface layer from chipping off. Additionally, melt extract stainless steel fibers also improve the durability and longevity of the concrete. The fibers enhance the resistance to corrosion, which is a common cause of spalling in concrete exposed to harsh environments or chemical attacks. By providing a protective layer against corrosion, the stainless steel fibers ensure that the concrete retains its integrity and remains resistant to spalling over an extended period. In conclusion, the addition of melt extract stainless steel fiber to concrete does improve its resistance to spalling. The fibers act as reinforcement, distributing stress and preventing cracks from propagating, while also enhancing the durability and corrosion resistance of the concrete.

- Q:How does melt extract stainless steel fiber improve the durability of fiber-reinforced concrete?

- Melt extract stainless steel fiber, as a highly effective material, significantly enhances the durability of fiber-reinforced concrete. This stainless steel fiber offers several key advantages that contribute to the overall strength and longevity of the concrete. To begin with, the incorporation of melt extract stainless steel fiber improves the crack resistance of fiber-reinforced concrete. These fibers possess high tensile strength and exceptional stress distribution capabilities within the concrete matrix. As a result, they effectively prevent the formation and propagation of cracks, even under heavy loads or extreme temperature fluctuations. By reducing crack occurrence, the overall durability and lifespan of the concrete structure are greatly enhanced. Furthermore, melt extract stainless steel fibers exhibit excellent corrosion resistance properties. Unlike other fiber types, these stainless steel fibers are highly resistant to chemical attacks, moisture, and aggressive substances. This corrosion resistance ensures the structural integrity of the fibers over time, even in harsh environments. Consequently, the concrete reinforced with melt extract stainless steel fibers is better equipped to withstand the deteriorating effects of water, chemicals, and other corrosive elements. In addition, melt extract stainless steel fibers enhance the impact and abrasion resistance of fiber-reinforced concrete. The strong and ductile nature of these fibers enables them to absorb and disperse energy efficiently. This characteristic makes the concrete more resistant to impacts, such as heavy loads or dynamic forces, which can cause cracking or surface damage. By improving the concrete's ability to withstand these external forces, the overall durability of the structure is significantly improved. Moreover, the addition of melt extract stainless steel fiber enhances the overall toughness of fiber-reinforced concrete. These fibers act as reinforcements, providing additional strength and ductility to the concrete matrix. This increased toughness allows the concrete to better resist various forms of loading, including bending, tension, and compression. As a result, the concrete becomes less prone to failure or damage, leading to a longer service life and improved durability. In conclusion, melt extract stainless steel fiber greatly enhances the durability of fiber-reinforced concrete by improving crack resistance, corrosion resistance, impact and abrasion resistance, as well as overall toughness. These fibers reinforce the structure and aid in stress distribution, thereby preventing crack formation and propagation. Moreover, their resistance to corrosion ensures long-term structural integrity, even in challenging environments. The increased impact and abrasion resistance, along with enhanced toughness, make the concrete more resistant to external forces, further improving its durability. Overall, the use of melt extract stainless steel fiber is a highly effective approach to enhance the durability and longevity of fiber-reinforced concrete structures.

- Q:Can melt extract stainless steel fiber be used in tunnel linings?

- Certainly! Melt extract stainless steel fiber is a suitable option for reinforcing tunnel linings. Tunnel linings often utilize stainless steel fibers to enhance the concrete's durability and strength. These fibers act as reinforcement, offering additional crack resistance and tensile strength to the concrete. Melt extract stainless steel fibers are particularly beneficial for tunnel linings due to their remarkable resistance to corrosion, an essential quality in an environment where moisture and chemicals may be present. Moreover, these fibers possess exceptional thermal stability, making them suitable for tunnels that may face high temperatures. In summary, melt extract stainless steel fibers are a dependable and efficient choice for reinforcing tunnel linings.

1. Manufacturer Overview |

|

|---|---|

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Melt Extract Stainless Steel Fiber 310

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords