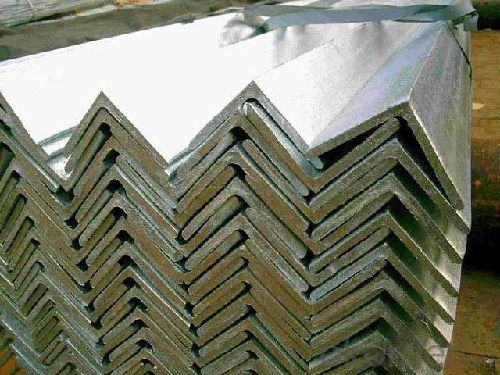

Steel Angle Bar Middle Size

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Steel Angle Bar Middle Size at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Steel Angle Bar Middle Size are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Angle Bar Middle Size are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:How are steel I-beams used in commercial construction?

- Steel I-beams are commonly used in commercial construction as structural support elements. These beams are designed to withstand heavy loads and provide stability to the building. They are often used as columns, beams, and framework in the construction of high-rise buildings, warehouses, bridges, and other large-scale structures. The I-shape of the beam helps distribute the weight evenly, making it a reliable choice for supporting heavy loads over long spans.

- Q:Are there any health or safety concerns associated with steel I-beams?

- Yes, there can be health and safety concerns associated with steel I-beams. Here are a few examples: 1. Installation Hazards: During the installation of steel I-beams, there is a risk of accidents or injuries due to the heavy weight and size of the beams. Proper lifting techniques and safety precautions should be followed to prevent accidents. 2. Structural Integrity: If steel I-beams are not properly designed, manufactured, or installed, there is a risk of structural failure. This can lead to collapses or accidents, posing significant safety hazards to workers or occupants of the building. 3. Fire Resistance: Steel I-beams are susceptible to heat and can lose their strength when exposed to high temperatures. In the event of a fire, the structural integrity of the building can be compromised, potentially endangering the lives of occupants. 4. Corrosion: If steel I-beams are not adequately protected against corrosion, they can deteriorate over time. Corroded beams may lose their strength, posing safety risks to the structure. Regular maintenance and inspection are crucial to identify and address any signs of corrosion. 5. Noise and Vibration: Steel I-beams can transmit noise and vibrations throughout the structure, especially in buildings with heavy machinery or equipment. Prolonged exposure to excessive noise and vibrations can have detrimental effects on human health, such as hearing loss or musculoskeletal disorders. It is important to prioritize safety measures and consult with professionals, such as structural engineers and construction experts, to ensure that steel I-beams are installed and maintained properly, minimizing any potential health or safety concerns.

- Q:What are the common challenges in erecting steel I-beams on-site?

- When it comes to erecting steel I-beams on-site, there are numerous common challenges that can arise. One of the primary obstacles involves ensuring the proper alignment and positioning of the beams. Given their size and weight, maneuvering and lifting I-beams into place can be quite difficult. To ensure correct alignment and secure fit, precise measurements and meticulous planning are imperative. Another challenge lies in the requirement for specialized equipment and skilled labor. The process of erecting steel I-beams often necessitates the use of cranes, hoists, and other heavy machinery. These tools must be operated by trained professionals who possess a thorough understanding of the specific requirements and safety protocols associated with working with steel beams. The lack of access to such equipment and skilled labor can pose a significant hurdle during the erection process. Furthermore, the weight of steel I-beams can create challenges during transportation and installation. These beams typically exhibit considerable heaviness, necessitating careful coordination and planning to ensure that the site is adequately prepared to handle the weight. Additionally, the need for proper safety precautions, such as securely fastening the beams and ensuring proper bracing, adds complexity to the process. Moreover, weather conditions can also present challenges during the erection of steel I-beams. High winds, rain, or extreme temperatures can impact the stability of the beams and jeopardize the safety of the workers involved. It is crucial to closely monitor weather conditions and implement appropriate measures to mitigate any potential risks. Lastly, coordinating and communicating among the various stakeholders involved in the construction project can prove to be a challenge. Erecting steel I-beams often requires collaboration between architects, engineers, contractors, and subcontractors. Effective communication and coordination between these parties are pivotal in ensuring that the beams are installed correctly and meet the project's requirements. In conclusion, the challenges encountered while erecting steel I-beams on-site encompass alignment and positioning, the need for specialized equipment and skilled labor, the weight of the beams, weather conditions, and coordination among project stakeholders. Successfully addressing these challenges necessitates careful planning, expertise, and effective communication to guarantee a safe and successful installation process.

- Q:Can steel I-beams be used in retail or commercial buildings?

- Yes, steel I-beams can be used in retail or commercial buildings. Steel I-beams are commonly used in the construction industry due to their strength, durability, and versatility. They provide structural support and can withstand heavy loads and stresses, making them suitable for large retail or commercial buildings. Steel I-beams also allow for open and flexible floor plans, enabling the creation of spacious and customizable retail or commercial spaces. Additionally, steel I-beams are fire-resistant and have a high resistance to pests, which makes them a reliable choice for commercial structures. Overall, steel I-beams are a popular choice for retail or commercial buildings due to their structural integrity, design flexibility, and long-term cost-effectiveness.

- Q:What are the advantages of using painted steel I-beams?

- There are several advantages of using painted steel I-beams in construction projects. Firstly, the paint coating on the steel I-beams provides a protective barrier against corrosion and rust. Steel is vulnerable to oxidation when exposed to moisture and chemicals, but the paint acts as a shield, preventing contact between the metal and these elements. This extends the lifespan of the I-beams and reduces the need for frequent maintenance or replacement. Secondly, painted steel I-beams offer enhanced aesthetics to the overall structure. The paint can be customized to match the desired color scheme or architectural style, making the beams blend seamlessly with the surrounding elements. This allows for a more visually appealing and cohesive appearance, enhancing the overall appeal and value of the building. Furthermore, the application of paint on steel I-beams can also improve their visibility and safety. By using high-visibility paint, the beams become more noticeable in low-light conditions, increasing safety for workers and pedestrians. This is particularly beneficial in industrial or construction settings where heavy machinery or vehicles operate near these beams. Additionally, painted steel I-beams offer easier identification and labeling within a construction site. By assigning different colors or markings to specific beams, it becomes simpler to identify and track their location and purpose. This aids in the organization and efficiency of the construction project, reducing errors and saving time. Lastly, painted steel I-beams are cost-effective in the long run. While the initial investment may be slightly higher compared to unpainted beams, the added protection against corrosion and rust significantly reduces maintenance and repair costs over time. Additionally, the enhanced durability of the painted beams ensures a longer lifespan, minimizing the need for replacement or repairs. In conclusion, the advantages of using painted steel I-beams include corrosion protection, enhanced aesthetics, improved visibility and safety, easier identification, and long-term cost savings. These benefits make painted steel I-beams a popular choice in various construction applications.

- Q:Are steel I-beams cost-effective compared to other structural options?

- Comparatively, steel I-beams are a cost-effective option when compared to alternative structural choices. Steel, being an incredibly durable and versatile material, offers numerous advantages in terms of strength, load-bearing capacity, and longevity. A notable feature of steel I-beams is their exceptional strength-to-weight ratio, allowing them to bear heavy loads while utilizing minimal material. This not only reduces construction expenses but also maximizes available space efficiency. Moreover, steel is readily accessible, making it a more convenient and cost-effective sourcing option when compared to other alternatives. Additionally, steel is highly recyclable, making it an environmentally conscious choice. The longevity of steel I-beams ensures a prolonged lifespan, reducing the need for frequent repairs or replacements, thereby further contributing to their cost-effectiveness. Furthermore, steel structures can be prefabricated, resulting in reduced construction time and labor expenses. The ease of assembly and modular nature of steel I-beams make them suitable for a wide range of applications, including residential, commercial, and industrial projects. However, it is crucial to acknowledge that the cost-effectiveness of steel I-beams may vary depending on various factors, such as project requirements, design complexity, and regional material availability. Therefore, it is advisable to consult with structural engineers and construction professionals to accurately assess the specific needs and constraints of a project and determine the most cost-effective solution.

- Q:Are steel I-beams suitable for load-bearing walls or partitions?

- Generally, steel I-beams are not suitable for load-bearing walls or partitions. Instead, their main purpose is to provide structural support in vertical applications, like building frames or bridges. Their design is focused on carrying heavy vertical loads, such as the weight of a building or bridge. In contrast, load-bearing walls or partitions are intended to bear both vertical and horizontal loads. They must support the weight of the structure above and withstand lateral forces like wind or seismic activity. Materials used for load-bearing walls or partitions, such as concrete, masonry, or wood, are chosen specifically for their ability to handle these types of loads. They have superior resistance to lateral forces and distribute the load evenly across the wall or partition. While steel I-beams can offer support and reinforcement to load-bearing walls or partitions, they are typically not the primary load-bearing element in these applications. Therefore, it is more appropriate to utilize materials specifically designed for load-bearing walls or partitions rather than relying on steel I-beams.

- Q:Can steel I-beams be used for curtain walls?

- No, steel I-beams are typically not used for curtain walls. Curtain walls are typically made of aluminum or glass, as they are lightweight and provide better insulation and aesthetic appeal. Steel I-beams are more commonly used for structural support in buildings.

- Q:Do steel I-beams require any maintenance?

- Yes, steel I-beams do require maintenance. Regular inspections should be conducted to identify any signs of corrosion, damage, or structural issues. Additionally, cleaning, painting, and applying protective coatings can help prevent rust and extend the lifespan of the beams.

- Q:How do Steel I-Beams perform in terms of insulation?

- Steel I-beams do not provide any insulation as they are primarily used for structural support and load-bearing purposes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Angle Bar Middle Size

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords