HR Steel Equal Beams with High Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

.

.

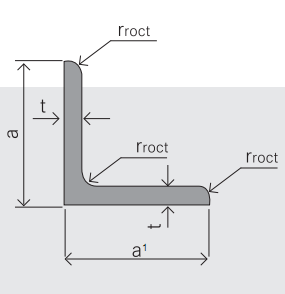

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery:

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q:How do you install steel I-beams correctly?

- Careful planning and proper execution are necessary for the correct installation of steel I-beams to ensure safety and structural integrity. Follow these step-by-step instructions to install steel I-beams correctly: 1. Select suitable beam size and length: Calculate the load-bearing requirements and span distance to choose the appropriate steel I-beam size and length. To ensure accuracy, consult a structural engineer or professional. 2. Prepare the site: Clear the area where the I-beams will be installed by removing debris and obstructions. Ensure that the foundation or supporting structure is in place and meets the necessary specifications. 3. Clean and inspect the I-beams: Thoroughly clean the steel I-beams to remove dirt, rust, or debris that could affect their stability. Inspect the beams for any defects or damage and address them accordingly. 4. Position the I-beams: Lift the I-beams carefully into position using suitable lifting equipment, such as a crane or forklift. Ensure proper alignment with the foundation or supporting structure. 5. Secure the I-beams: Use appropriate connectors or brackets to fasten the I-beams securely to the foundation or supporting structure. Follow the manufacturer's specifications and use the correct type and size of connectors. 6. Check alignment and level: Verify that the installed I-beams are level and properly aligned. Use a spirit level or laser level for accuracy. Make adjustments if necessary. 7. Weld or bolt connections: Depending on the design and specifications, secure the connections between the I-beams and other structural components by welding or bolting. Follow safety procedures and adhere to welding or bolting codes and standards. 8. Inspect and reinforce: Conduct a thorough inspection of the installed I-beams, paying attention to welds, connections, and potential stress points. Strengthen weak areas or make necessary adjustments as recommended by the engineer. 9. Obtain necessary approvals: Ensure that the installation complies with local building codes and regulations before proceeding with further construction or load-bearing activities. Obtain required permits and inspections. 10. Seek professional assistance: If you lack experience or confidence in installing steel I-beams, it is important to consult a professional or structural engineer to oversee the process and provide guidance. They can ensure correct installation and compliance with relevant standards and regulations. Always remember that the proper installation of steel I-beams is crucial for the structural integrity of a building or structure. Seeking professional advice and assistance is recommended to ensure a safe and accurate installation.

- Q:What are the different aesthetic options available for steel I-beams?

- The different aesthetic options available for steel I-beams include various surface finishes such as powder coating, galvanizing, or painting in different colors. Additionally, decorative elements like cladding or facade systems can be added to enhance the visual appeal of the beams.

- Q:How is I-beam connected?

- Connections between steel column and steel beam:1. The steel column is connected with the steel beam and the 2 stiffened plate is arranged in the direction of the steel beam. The distance between the stiffener and the steel beam is the height of the stiffener;2 、 steel column stiffener plate welding plate (open bolt hole), connecting plate height = steel beam web height;3. The connection between the steel beam and the steel column is bolted.

- Q:How do you calculate the deflection due to bending in a steel I-beam?

- To determine the deflection caused by bending in a steel I-beam, one can utilize the Euler-Bernoulli beam theory. This theory assumes that the beam possesses a long and slender structure, with a deflection that is considerably smaller compared to its length. The initial step in the calculation of the deflection involves the determination of the bending moment at the specific point of interest within the beam. This can be accomplished through an analysis of the external loads and supports applied to the beam. Once the bending moment has been ascertained, the following formula can be employed: δ = (5 * M * L^3) / (384 * E * I) Here, δ represents the deflection, M denotes the bending moment, L signifies the length of the beam, E corresponds to the modulus of elasticity of the steel, and I denotes the moment of inertia of the beam's cross-sectional shape. The moment of inertia (I) serves as a measure of the beam's resistance to bending and can be calculated based on the cross-sectional dimensions of the beam. In the case of an I-beam, it is typically given by the following equation: I = (b * h^3 - b' * h'^3) / 12 In this equation, b and h represent the dimensions of the top and bottom flanges respectively, while b' and h' represent the dimensions of the web. The modulus of elasticity (E) is a material property of steel and can be obtained from engineering references or material data sheets. By substituting the values for the bending moment, length, modulus of elasticity, and moment of inertia into the deflection formula, one can accurately determine the deflection caused by bending in a steel I-beam. It is important to note that this formula assumes linear elastic behavior and disregards factors such as shear deformation and non-linear material properties, which may impact the actual deflection.

- Q:How do steel I-beams perform in terms of earthquake resistance for renovations?

- Steel I-beams are highly effective in providing earthquake resistance for renovations. Due to their high strength and stiffness, they can effectively absorb and distribute seismic forces, reducing the risk of structural failure during an earthquake. Additionally, steel I-beams can be easily integrated into existing structures, making them a popular choice for retrofitting projects. Their excellent performance in seismic events makes them a reliable and durable option for enhancing earthquake resistance in renovations.

- Q:How are steel I-beams protected against rust and corrosion during storage?

- To prevent rust and corrosion during storage, steel I-beams are commonly safeguarded using various methods. One such method involves applying a protective coating, such as paint or galvanizing, which acts as a barrier between the steel and the environment. This barrier effectively hinders the formation of rust and corrosion by preventing direct contact between the metal surface and moisture or oxygen. When using paint as a protective coating, a layer of primer is typically applied first to improve adhesion and corrosion resistance. This is then followed by one or more layers of paint to provide additional protection. The choice of paint type and quality depends on factors such as the duration of storage and expected environmental conditions. Alternatively, galvanizing is widely employed to protect steel I-beams. This process involves coating the steel with a layer of zinc through hot-dip galvanizing or electroplating. Zinc acts as a sacrificial anode, corroding before the steel does. This sacrificial corrosion process effectively safeguards the steel against rust and corrosion. In addition to protective coatings, steel I-beams can be stored in controlled environments with reduced humidity levels or in specially designed storage facilities that minimize exposure to moisture and corrosive elements. Regular inspections and maintenance are essential to detect and address any signs of rust or corrosion that may occur despite these preventive measures. Overall, a combination of protective coatings, controlled environments, and proper maintenance practices ensures that steel I-beams remain free from rust and corrosion during storage.

- Q:What are the common design standards for steel I-beams?

- The common design standards for steel I-beams are established by various organizations and regulatory bodies that aim to ensure the safe and efficient use of these structural components. Some of the widely recognized design standards for steel I-beams include: 1. American Institute of Steel Construction (AISC): The AISC is a leading organization in the United States that develops design standards and specifications for structural steel. Its publication, the AISC Manual of Steel Construction, provides comprehensive guidelines for the design, fabrication, and erection of steel structures, including I-beams. 2. European Committee for Standardization (CEN): The CEN develops and publishes European standards for various engineering disciplines. The Eurocode series, specifically Eurocode 3 - Design of Steel Structures, provides design rules and procedures for steel structures, including I-beams, in European countries. 3. British Standards Institution (BSI): The BSI is the national standards body of the United Kingdom, and it issues design standards for steel structures. The British Standard BS 5950 series, particularly BS 5950-1:2000 - Structural Use of Steelwork in Building - Code of Practice for Design - Rolled and Welded Sections, includes guidelines for the design of I-beams and other steel sections. 4. Canadian Standards Association (CSA): The CSA develops and publishes design standards for various industries in Canada. The CSA Standard S16 - Design of Steel Structures provides guidance for the design, fabrication, and construction of steel structures, including I-beams. 5. International Organization for Standardization (ISO): The ISO is an international standard-setting body that develops and publishes standards applicable to various industries. ISO 630-3:2012 - Structural Steels - Part 3: Technical Delivery Conditions for Fine Grain Structural Steels specifies technical delivery conditions for hot-rolled steel plates, sheets, and wide-flange sections used in the construction of I-beams. These design standards cover aspects such as material properties, allowable stresses, geometric dimensions, load capacities, and fabrication requirements for steel I-beams. They aim to ensure that I-beams are designed and used safely and efficiently, meeting specific structural and performance requirements. It is essential for engineers, architects, and fabricators to adhere to these standards to ensure the structural integrity and safety of steel I-beam applications.

- Q:Are there any alternatives to steel I-beams for structural support in construction?

- Yes, there are numerous options for structural support in construction instead of steel I-beams. One possibility is to utilize reinforced concrete beams, which involve embedding steel rebar within the concrete. This combination allows for both the compressive strength of concrete and the tensile strength of steel, resulting in highly durable beams capable of withstanding heavy loads. Another option is the use of laminated timber beams, also known as glulam beams. These beams are created by bonding multiple layers of timber together using adhesives. As a result, they are not only strong and lightweight but also aesthetically pleasing. Glulam beams offer a sustainable alternative to steel since they are made from renewable resources and have a lower carbon footprint. In addition, engineered wood products like laminated veneer lumber (LVL) and parallel strand lumber (PSL) can serve as alternatives to steel I-beams. LVL is manufactured by layering thin wood veneers and bonding them together, creating a robust and dimensionally stable beam. PSL, on the other hand, is produced by aligning and bonding wood strands, resulting in a beam with high strength and stiffness. Fiber-reinforced polymers (FRP) are also emerging as an alternative to steel I-beams. FRP composites consist of fibers embedded in a polymer matrix, such as carbon fiber reinforced polymer (CFRP) or glass fiber reinforced polymer (GFRP). These materials offer excellent strength-to-weight ratios, corrosion resistance, and durability. However, they are still undergoing research and development for widespread use in construction. In conclusion, despite the common utilization of steel I-beams for structural support in construction, there are several viable alternatives available, including reinforced concrete beams, laminated timber beams, engineered wood products, and fiber-reinforced polymers. The choice of an alternative will depend on various factors such as load requirements, design preferences, sustainability objectives, and cost considerations.

- Q:How do steel I-beams perform in high humidity areas?

- Steel I-beams perform well in high humidity areas as they are made from a combination of iron and carbon, which makes them highly resistant to corrosion and moisture damage. The steel is typically coated with protective coatings or paint to further enhance its resistance to humidity. Additionally, I-beams are designed to distribute weight evenly, providing excellent structural support even in moist environments. Therefore, steel I-beams are a reliable choice for construction projects in high humidity areas, ensuring durability and longevity in such conditions.

- Q:How do you determine the appropriate size of a steel I-beam for a specific application?

- To determine the appropriate size of a steel I-beam for a specific application, several factors need to be considered. These include the load requirements, span length, support conditions, and the material properties of the beam. Engineers typically use structural analysis and design calculations to evaluate these factors and select the appropriate size of the I-beam that can safely support the anticipated load and meet the structural requirements of the application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HR Steel Equal Beams with High Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords