IPEAA IPE/ beam steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

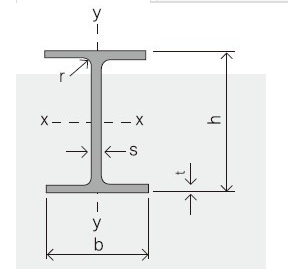

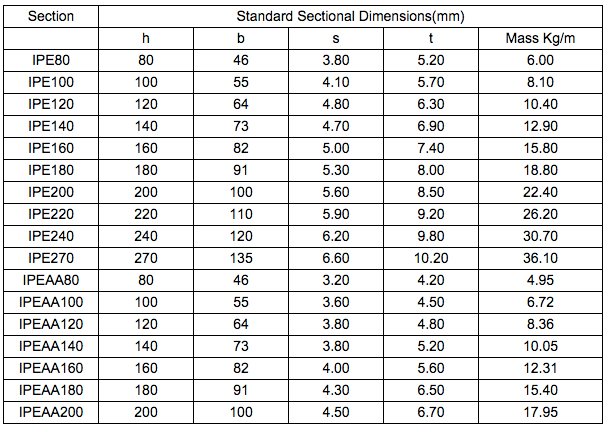

Specifications of IPE/IPEAA Beam Steel

1. Product name: IPE/IPEAA Beam Steel

2. Standard: EN10025, GB Standard, ASTM, JIS etc.

3. Grade: Q235B, A36, S235JR, Q345, SS400 or other equivalent.

4. Length: 5.8M, 6M, 9M, 10M, 12M or as your requirements

Applications of IPE/IPEAA Beam Steel

IPE/IPEAA Beam Steel are widely used in various construction structures, bridges, autos, brackets, mechanisms and so on.

Packing & Delivery Terms of IPE/IPEAA Beam Steel

1. Package: All the IPE/IPEAA Beam Steel will be tired by wire rod in bundles

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Shipment: In containers or in bulk cargo

5. Delivery time: All the IPE/IPEAA Beam Steel will be at the port of the shipment within 45 days after receiving the L/C at sight ot the advance pyment.

6. Payment: L/C at sight; 30% advance payment before production, 70% before shipment by T/T, etc.

Production flow of IPE/IPEAA Beams

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q:Can steel I-beams be used for bridge construction?

- Yes, steel I-beams can be used for bridge construction. Steel I-beams are commonly used in bridge construction due to their high strength and durability. They provide excellent load-bearing capabilities, making them suitable for supporting heavy loads such as vehicles and pedestrians. Additionally, steel I-beams are resistant to corrosion and can withstand harsh weather conditions, making them ideal for building bridges that need to withstand various environmental factors. The versatility of steel I-beams allows engineers to design bridges of various spans and shapes, making them a popular choice in modern bridge construction. Overall, steel I-beams are a reliable and efficient choice for bridge construction.

- Q:Can Steel I-Beams be used for solar panel installations?

- Solar panel installations can indeed utilize steel I-beams. These beams are widely employed in construction due to their impressive strength and durability. Their ability to provide exceptional support for heavy loads makes them an excellent choice for bearing the weight of solar panels. Moreover, steel I-beams can be effortlessly installed and interconnected, creating a robust framework for mounting solar panels. However, it is crucial to ensure that the I-beams are appropriately sized and designed to withstand the specific load and wind conditions associated with solar panel installations. Consulting a structural engineer or a professional solar panel installer is highly recommended to guarantee the secure and efficient utilization of steel I-beams for solar panel installations.

- Q:Can steel I-beams be used in data centers or technology facilities?

- Yes, steel I-beams can be used in data centers or technology facilities. Steel I-beams are commonly used in construction due to their high strength and durability. In data centers and technology facilities, where heavy equipment such as servers and storage racks are installed, steel I-beams can provide the necessary structural support to handle the weight and load of the equipment. Furthermore, steel I-beams offer various advantages for data centers and technology facilities. They have a high load-bearing capacity, which means they can support heavy loads without flexing or bending. This is crucial for ensuring the stability and safety of the facility. Steel I-beams are also fire-resistant, which is crucial in data centers where the risk of fire can have catastrophic consequences. The fire-resistant properties of steel I-beams can help prevent the collapse of the structure and provide additional time for evacuation or firefighting efforts. Additionally, steel I-beams can be designed and engineered to meet specific requirements and load capacities. This flexibility allows for customization and optimization of the structural design, ensuring that the data center or technology facility can accommodate the specific needs and equipment configurations. Overall, steel I-beams are a reliable and commonly used structural element in data centers and technology facilities due to their strength, durability, fire resistance, and flexibility in design.

- Q:How are steel I-beams protected from corrosion?

- There are several methods available to protect steel I-beams from corrosion. Among them, one commonly used approach is to apply a protective coating. This coating can take the form of paint, epoxy, or a zinc-based material. Its purpose is to act as a barrier, preventing moisture and oxygen from reaching the metal surface and causing corrosion. Additionally, steel I-beams can also undergo galvanization. This process entails applying a layer of zinc to the beams, either through hot-dip galvanizing or electroplating. The zinc coating serves as sacrificial protection, corroding in place of the steel and effectively safeguarding the I-beams against rust. Another method for corrosion protection is cathodic protection. This technique involves connecting the steel I-beams to a sacrificial anode, such as zinc or aluminum, using a conductive material. By doing so, the anode corrodes instead of the steel, thus preserving the integrity of the I-beams. To ensure the continued effectiveness of these protective measures, regular maintenance and inspection are essential.

- Q:How many kilograms per kilo is I-beam 16?

- The theoretical weight of No. 16 I-beam is 20.513 kg / m..

- Q:Are there any health and safety considerations when working with steel I-beams?

- When working with steel I-beams, there are multiple health and safety considerations to take into account. These considerations encompass the following: 1. Personal Protective Equipment (PPE): To safeguard against potential dangers such as falling objects, cuts, and impacts, workers must consistently wear suitable PPE including safety glasses, steel-toed boots, gloves, and hard hats. 2. Manual Handling: Proper lifting techniques are necessary to prevent strains, sprains, or other musculoskeletal injuries caused by the weight of steel I-beams. Workers should undergo adequate training on safe lifting and moving methods, and whenever possible, mechanical lifting aids should be utilized. 3. Structural Stability: Prior to commencing work with steel I-beams, it is crucial to verify the stability and capacity of the supporting structure to prevent collapse or structural failures. Structural engineers should assess the integrity of the structure to ensure it can withstand the weight of the beams and the workers. 4. Falls from Heights: Given that working with steel I-beams often involves tasks performed at elevated positions during installation or maintenance, measures for fall protection such as guardrails, safety nets, or personal fall arrest systems must be in place. These precautions are vital to prevent falls and safeguard workers against severe injuries. 5. Welding and Cutting Hazards: The fabrication or modification of steel I-beams may necessitate welding or cutting processes that produce hazardous fumes, sparks, and intense heat. To minimize risks associated with these operations, adequate ventilation, fire prevention measures, and comprehensive training in welding and cutting techniques are imperative. 6. Hazardous Materials: Certain steel I-beams may be coated with paints, coatings, or preservatives containing hazardous substances like lead or asbestos. Workers should be aware of these potential hazards and follow proper safety procedures, such as utilizing respiratory protection and employing appropriate handling techniques, to prevent exposure. In summary, working with steel I-beams necessitates strict adherence to safety protocols in order to protect workers from various hazards arising from the weight, structural integrity, height, welding processes, and potential exposure to hazardous materials.

- Q:Can steel I-beams be used for industrial structures?

- Yes, steel I-beams can be used for industrial structures. Steel I-beams are commonly used in the construction industry due to their high strength-to-weight ratio, which allows for the creation of large and durable structures. Industrial structures such as warehouses, manufacturing plants, and power plants often require a strong and reliable support system, and steel I-beams provide the necessary structural integrity. Additionally, steel I-beams are versatile and can be easily fabricated and customized to meet specific design requirements, making them a preferred choice for industrial construction projects.

- Q:How do you calculate the shear capacity of steel I-beams?

- To calculate the shear capacity of steel I-beams, you need to consider the shear force acting on the beam and its resistance to shearing. The shear capacity can be determined using the following steps: 1. Determine the shear force acting on the beam: This can be obtained from the structural analysis of the overall structure or by considering the loads and their distribution on the beam. The shear force is typically expressed in units of force (kN or lb). 2. Calculate the shear stress: Shear stress is calculated by dividing the shear force by the cross-sectional area of the beam. The cross-sectional area is the product of the width of the flanges and the thickness of the web. 3. Determine the shear yield strength: This is the maximum shear stress that the steel can withstand without permanent deformation. It can be obtained from the steel material specifications or design codes. The yield strength is typically expressed in units of stress (MPa or psi). 4. Check for shear failure: Compare the calculated shear stress with the shear yield strength. If the calculated shear stress is less than the shear yield strength, the beam is safe from shear failure. However, if the calculated shear stress exceeds the shear yield strength, the beam may experience shear failure. It is important to note that the shear capacity of steel I-beams can also be influenced by factors such as the beam's length, moment of inertia, and the type and size of the connections. Therefore, it is advisable to consult design codes or engineering handbooks for more detailed calculations and considerations specific to the particular beam and its application.

- Q:Will the raw material of I-beam and channel steel be re examined?

- The inspection of the incoming materials of I-beam and channel steel is no longer necessary for re examination

- Q:What is the difference between I-beam and H steel?

- There are hot rolled I-beam and hot rolled H section steel. Only welded type H steel, without welded i-beam. 2. the meaning of "I-beam" does not include H steel. They are of the two type.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

IPEAA IPE/ beam steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords