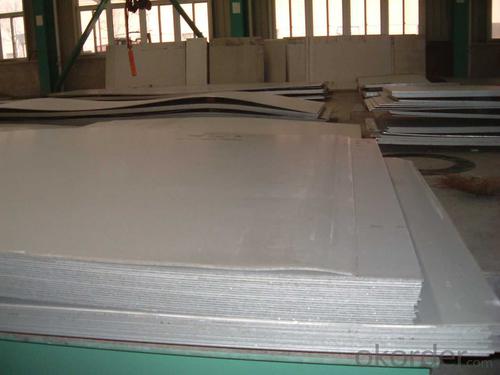

Stainless Steel sheet 443 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/316l/321,410/420/430/444/443/409L, and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

FAQ:

1. What's the quality?

very fine

2. How long get reply?

within 24 hours

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q:Can stainless steel sheets be used for elevator mirror panels?

- Yes, stainless steel sheets can be used for elevator mirror panels. Stainless steel is a durable and corrosion-resistant material that is commonly used in the construction of elevator interiors. Additionally, stainless steel can be polished to a high shine, making it suitable for mirror panels in elevators.

- Q:Can stainless steel sheets be used in high-pressure environments?

- Yes, stainless steel sheets can be used in high-pressure environments. Stainless steel is known for its excellent strength, durability, and corrosion resistance, making it suitable for applications that require withstanding high pressure conditions. The material's ability to resist deformation and maintain its integrity under extreme pressure makes it a preferred choice in industries such as oil and gas, chemical processing, and aerospace.

- Q:What is the maximum width of stainless steel sheets available?

- The supplier and customer requirements can cause variations in the maximum width of stainless steel sheets. Typically, these sheets come in widths ranging from 36 inches (91.44 cm) to 72 inches (182.88 cm). However, certain specialty suppliers may have wider options, exceeding 96 inches (243.84 cm) or even more. It is crucial to consider that wider sheets might incur higher production expenses and longer delivery times. Therefore, customers should consult their supplier to ascertain the maximum width suitable for their particular demands.

- Q:Can stainless steel sheets be used for magnetic shielding?

- To a certain extent, stainless steel sheets can be utilized for magnetic shielding. Although stainless steel is not intrinsically magnetic, it possesses some magnetic properties due to the presence of iron, a magnetic material, in stainless steel alloys. This enables stainless steel sheets to exhibit weak magnetic characteristics. Nevertheless, the magnetic shielding capabilities of stainless steel sheets are limited when compared to materials specifically engineered for magnetic shielding, such as mu-metal or nickel-iron alloys. These materials have a higher permeability, meaning they can redirect and absorb magnetic fields more efficiently than stainless steel. However, stainless steel sheets can still offer some level of magnetic shielding, particularly in environments with lower intensity magnetic fields. They can assist in reducing the transmission of magnetic fields from one area to another, which can be beneficial in certain applications. Nonetheless, for situations that require high-intensity or sensitive magnetic shielding, it is recommended to utilize specialized magnetic shielding materials for optimal effectiveness.

- Q:Which is better, stainless steel plate kitchen?

- According to the organizational structure of classification at room temperature, a martensitic, Austenitic, Ferritic and duplex stainless steel; according to the classification of the main chemical components, basically can be divided into chromium and chromium nickel stainless steel two systems; by use of minute nitric acid resistant stainless steel, stainless steel, stainless steel corrosion resistance to sulfuric acid and so on, according to the corrosion resistance the type can be divided into stainless steel pitting corrosion, stress corrosion resistant stainless steel, intergranular corrosion resistant stainless steel etc.;

- Q:Can stainless steel sheets be used for jewelry making?

- Yes, stainless steel sheets can be used for jewelry making. Stainless steel is a popular material for creating jewelry due to its durability, resistance to tarnishing, and hypoallergenic properties. It can be easily cut, shaped, and textured to create unique designs. Stainless steel sheets can be used to make various types of jewelry, including earrings, rings, bracelets, pendants, and even intricate chains. Additionally, stainless steel jewelry is often more affordable compared to precious metals like gold or silver, making it a popular choice for budget-conscious individuals or those looking for a more modern and industrial aesthetic.

- Q:What welding equipment do we need for welding stainless steel sheet and stainless steel square tube?

- 1 argon arc welding machine! If the person who has not been married, as little as possible, that thing has radiation, long time use of physiology is influential. You know what you do.2, regardless of the front and back can be, as long as it looks beautiful and practical.3, welding technology is good, it will not be ugly after welding.4, only the use of technology to make up for the lack of machinery, and then cattle B hardware, there is no good software is not good.5, welding rod, protective mask and so on.

- Q:Can stainless steel sheets be used for decorative panels?

- Yes, stainless steel sheets can be used for decorative panels. The versatility, durability, and sleek appearance of stainless steel make it a popular choice for various decorative applications, including panels. It can be used to create modern and stylish designs in both residential and commercial settings.

- Q:Can stainless steel sheets be used for food packaging equipment?

- Food packaging equipment can utilize stainless steel sheets, as they possess several desirable qualities. Due to their durability, corrosion resistance, and hygienic properties, stainless steel is a popular choice for food processing and packaging equipment. Notably, it is non-reactive, ensuring that the food's quality and taste remain unaffected. Moreover, stainless steel sheets are easily cleaned and sanitized, making them appropriate for use in food packaging equipment where cleanliness and hygiene are vital. Additionally, the smooth surface of stainless steel prevents food particles from adhering to the equipment, further enhancing its usability. In summary, stainless steel sheets offer a dependable and secure solution for food packaging equipment.

- Q:How do I determine the hardness of stainless steel sheets?

- There are various techniques available for determining the hardness of stainless steel sheets. One commonly used method is the Rockwell hardness test, which involves measuring the depth of penetration of an indenter into the material. The Rockwell scale offers different scales for different materials, so it is essential to select the appropriate scale for stainless steel. To conduct the Rockwell hardness test, you will require a Rockwell hardness tester and either a diamond or tungsten carbide indenter. Begin by placing the stainless steel sheet on a stable, flat surface. Next, position the indenter on the surface of the sheet and apply a minor load. Once the minor load is applied, proceed to apply the major load until it reaches its maximum value. After the load has been applied and released, the hardness value will be displayed on the dial or digital display of the Rockwell hardness tester. This value corresponds to a specific hardness scale, such as HRC for stainless steel. It is important to remember that the Rockwell hardness test provides a relative measurement of hardness and may not accurately reflect the physical properties of the material. Moreover, the hardness of stainless steel can vary depending on factors such as alloy composition, heat treatment, and manufacturing process. Therefore, it is advisable to consult the material's specifications or conduct additional tests to obtain a more accurate and comprehensive understanding of the stainless steel sheet's hardness.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel sheet 443 with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords