Stainless steel 316 polished round bar H11 tolerance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

2.5-500

Length:

6000

Net Weight:

1-5T

Stainless steel bars,profiles,beams

Product Information:

1) Product feature:

| 1. Product: | Stainless steel 316 polished round bar, 316 stainless steel bright round bar |

| 2. Steel type: | AISI 316 |

| 3. Standard: | ASTM A276, ASTM A484 |

| 4. Diameter: | From Ø1/4'' to Ø16'' ( Diameter: 6mm~400mm ) |

| Such as Ø1'', Ø2'', Ø2.5'', Ø3'', Ø3.5'', Ø4'', Ø4.5'', Ø4.5'', Ø5'',Ø6'', Ø7'', Ø8'' | |

| 5. Length: | 1~ 8meters |

| * Bright: peeled & polished, CNC machined, centreless grinding | |

| 6. Surface: | * Black |

| 7. Diameter tolerance: | H9, H11, H13, K9, K11, K13 etc…as per clients’ request |

| 8. Length tolerance: | 0/+50mm |

| 9. Finishing: | Solution treated |

| 10. Feature of 316L: | Addition of Molybdenum prevents specific forms of corrosion. Also known as "marine grade" |

| 11. Mechanical property: | T.S.: ≥515Mpa, Y.S.: ≥205Mpa, EL: ≥40%, Ruduction of area: ≥50% |

| 12. Application: | Shipbuilding industry, marine shaft, propeller shaft, transmission shaft |

| bolt & nuts, machine-made industry, food industry, paper mill equipment. | |

| 13. Delivery time | Generally within 15~20 days upon receipt the PO, as per the q’ty. |

| 14. Certificate: | ISO, BV, TUV, SGS, mill test certificate |

| 15. Package: | Good quality & fumigated wooden box, which can better protect the bars. ( See pictures below ) |

| 16. Experience:: | * Specialized in producing SS 316L round bar for propeller shaft purpose; |

| * Have a close connection with overseas shipyards , such as Indonesia, Thailand, Philippines, | |

| Singapore, Brazil, Canada etc., so have much experience in this field. |

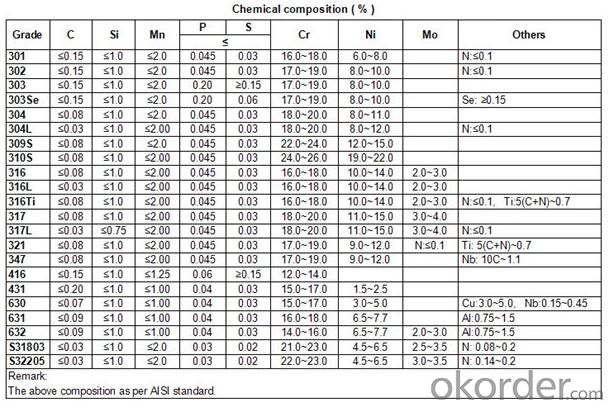

2) Chemical composition:

| Grade | Standard | C | Si | Mn | P | S | Cr | Ni | Mo |

| 316 | ASTM A276 | ≤0.08 | ≤1.0 | ≤2.00 | ≤0.045 | ≤0.03 | 16.0~18.0 | 10.0~14.0 | 2.0~3.0 |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q:Can stainless steel bars be used in the water treatment aftermarket?

- Indeed, the utilization of stainless steel bars in the water treatment aftermarket is feasible. Due to its high resistance to corrosion, stainless steel proves to be a suitable material for water treatment applications that involve frequent exposure to water and chemicals. Within water treatment systems, such as filter systems, pumps, valves, and piping, stainless steel bars can be employed. Their exceptional strength and durability guarantee the equipment's reliability and longevity. Furthermore, stainless steel is non-reactive, meaning it does not contaminate the treated water. This attribute has contributed to the widespread preference for stainless steel bars in the water treatment aftermarket, where the maintenance of efficient and effective water treatment processes necessitates the presence of high-quality and long-lasting components.

- Q:How are stainless steel bars used in the automotive industry?

- Stainless steel bars are extensively used in the automotive industry due to their exceptional properties and benefits. These bars are primarily employed in various components and systems to enhance the overall performance, durability, and safety of automobiles. One of the key uses of stainless steel bars in the automotive sector is for manufacturing exhaust systems. Due to their high resistance to corrosion and heat, stainless steel bars are an ideal material for constructing exhaust pipes, mufflers, and catalytic converters. These components are exposed to extreme conditions, such as high temperatures and corrosive gases, making the use of stainless steel bars crucial for longevity and optimal performance. Moreover, stainless steel bars are also utilized in the production of various engine components. The bars are commonly used for manufacturing crankshafts, camshafts, and valve stems due to their excellent strength, wear resistance, and ability to withstand high pressure and stress. These components ensure the smooth operation of the engine and contribute to the overall efficiency of the vehicle. Furthermore, stainless steel bars find application in the production of suspension and chassis components. The bars are employed in the construction of sway bars, control arms, and tie rods, which are responsible for providing stability, control, and handling characteristics to the vehicle. The high strength and corrosion resistance of stainless steel bars make them suitable for withstanding the constant stress and loads experienced by these components. Additionally, stainless steel bars are utilized in the automotive industry for manufacturing safety-related components. They are commonly used in the production of roll bars and roll cages, which provide protection to occupants in the event of a rollover accident. The superior strength and ductility of stainless steel bars ensure the necessary structural integrity and safety standards are met. Overall, stainless steel bars play a crucial role in the automotive industry by enhancing the performance, durability, and safety of various components and systems. Their exceptional properties make them a preferred material for manufacturing exhaust systems, engine components, suspension and chassis parts, as well as safety-related structures.

- Q:What are the tolerance specifications for stainless steel bars?

- The tolerance specifications for stainless steel bars rely on several factors, including the precise type or grade of stainless steel, the bars' dimensions, and their intended purpose. Generally, stainless steel bars are produced to meet specific industry standards or the demands of customers. In essence, the tolerance specifications for stainless steel bars are established by the permissible variation in dimensions like diameter, length, straightness, and surface finish. For instance, the diameter tolerance for stainless steel bars may vary from narrow tolerances of +/- 0.005 inches to more lenient tolerances of +/- 0.030 inches, depending on the bars' size and grade. Similarly, the length tolerance for stainless steel bars can differ based on the specified length and the desired level of accuracy. The tolerances for straightness ensure that the bars do not exceed allowable bending limits. Surface finish tolerances determine the acceptable imperfections on the bars' surface, such as scratches, pits, or roughness, which can impact their appearance or functionality. It is essential to recognize that different industries and applications may have specific tolerance requirements for stainless steel bars. For instance, aerospace or medical applications often necessitate tighter tolerances due to the critical nature of their usage. Therefore, it is crucial to refer to the relevant industry standards or specifications or collaborate closely with manufacturers or suppliers to determine the suitable tolerance specifications for stainless steel bars within a specific context.

- Q:Can stainless steel bars be molded or cast?

- No, stainless steel bars cannot be molded or cast. Stainless steel is typically formed through hot or cold rolling processes, where the metal is shaped into bars or other desired forms.

- Q:Can stainless steel bars be used in the pulp and paper industry?

- Indeed, the pulp and paper industry can utilize stainless steel bars. Renowned for its resistance to corrosion, stainless steel proves to be a fitting material for a plethora of applications within industries commonly exposed to chemicals, liquids, and high temperatures. Within the realm of the pulp and paper industry, stainless steel bars serve various purposes, including the fabrication of machinery components, the construction of tanks and vessels, and the design of conveyor systems. The unparalleled strength and durability of stainless steel render it an ideal choice for withstanding the demanding conditions and harsh environments typically encountered in pulp and paper mills. Furthermore, stainless steel's hygienic properties and ease of cleaning make it highly suitable for industries that impose stringent sanitation standards, guaranteeing the production of pristine and first-rate paper products.

- Q:Are stainless steel bars resistant to abrasion?

- Yes, stainless steel bars are highly resistant to abrasion. This is due to their unique composition, which includes a high percentage of chromium. The chromium content forms a protective layer on the surface of the stainless steel, known as passive film, which acts as a barrier against abrasion, corrosion, and other forms of damage. Additionally, stainless steel bars are often hardened through various heat treatment processes, further enhancing their resistance to abrasion. As a result, stainless steel bars are commonly used in industries that require materials with excellent durability and resistance to wear, such as construction, manufacturing, and automotive industries.

- Q:Can stainless steel bars be colored or tinted?

- Yes, stainless steel bars can be colored or tinted using various processes such as powder coating, anodizing, or electroplating to achieve different colors and finishes.

- Q:Are stainless steel bars suitable for outdoor furniture?

- Yes, stainless steel bars are highly suitable for outdoor furniture. Stainless steel is known for its exceptional durability and resistance to corrosion, making it an excellent choice for outdoor applications. It can withstand exposure to various weather conditions, including rain, sun, and humidity, without rusting or deteriorating. Additionally, stainless steel has a sleek and modern appearance that complements many outdoor design styles. It is also easy to clean and maintain, making it a practical choice for outdoor furniture that will last for many years.

- Q:What are stainless steel bars used for?

- Stainless steel bars possess durability, strength, and corrosion resistance properties that find extensive use in diverse industries. The construction industry frequently utilizes stainless steel bars to reinforce concrete structures like bridges, buildings, and highways, ensuring the longevity and structural integrity of these projects. In the manufacturing sector, stainless steel bars play a crucial role in producing machinery and equipment. These bars are machined, formed, or welded to create components that require high strength, heat resistance, chemical resistance, and wear resistance. Industries such as automotive, aerospace, and oil and gas heavily rely on stainless steel bars for manufacturing parts like shafts, valves, fasteners, and fittings. The food and beverage industry extensively utilizes stainless steel bars due to their non-reactive nature. This makes stainless steel an ideal material for food processing equipment, including conveyor systems, mixers, tanks, and storage containers. It ensures the safety and hygiene of food products by preventing contamination and facilitating easy cleaning. Furthermore, the marine industry heavily relies on stainless steel bars due to their excellent resistance to saltwater corrosion. These bars are commonly used in boat fittings, propeller shafts, and other components exposed to harsh marine environments. Additionally, stainless steel bars find application in architectural projects such as handrails, balustrades, and decorative elements. The aesthetic appeal, durability, and low maintenance requirements of stainless steel make it a popular choice for enhancing the appearance and functionality of buildings and public spaces. In conclusion, stainless steel bars serve diverse purposes across various industries. Their versatility, strength, and corrosion resistance make them indispensable in the construction, manufacturing, food processing, marine, and architectural sectors.

- Q:What are the different types of stainless steel bar finishes for decorative purposes?

- There are several different types of stainless steel bar finishes that are commonly used for decorative purposes. Some of the most popular finishes include brushed, polished, satin, mirror, and textured. These finishes give stainless steel bars a unique appearance and can be chosen based on the desired aesthetic effect.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless steel 316 polished round bar H11 tolerance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords