cold rolled stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless Steel round Bar

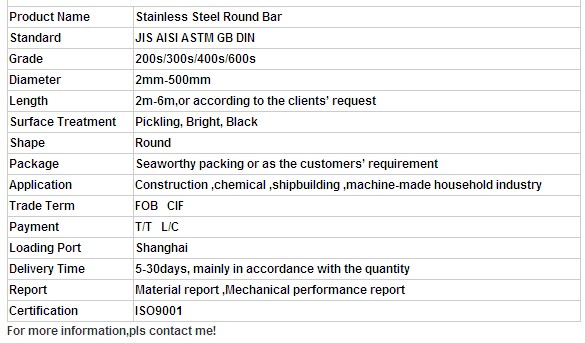

Specifications

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

A series of pictures

- Q:What are the different joining methods for stainless steel bars?

- When it comes to stainless steel bars, there are a variety of joining methods available depending on the specific application and requirements. Some commonly used methods include: 1. Welding: Among the most widely utilized techniques, welding involves melting the edges of the bars and allowing them to solidify, resulting in a strong bond. TIG welding, MIG welding, and spot welding are a few examples of welding techniques that can be employed. 2. Adhesive bonding: This method entails using a high-strength adhesive to join the stainless steel bars together. Adhesive bonding can be effective for complex shapes or when a more visually pleasing appearance is desired. However, it may not be suitable for applications requiring high strength or resistance to extreme temperatures. 3. Mechanical fastening: This method involves using mechanical fasteners like bolts, screws, or rivets to connect the stainless steel bars. Mechanical fastening is a quick and cost-effective joining method that allows for easy disassembly if necessary. However, it may not offer the same level of strength as welding or adhesive bonding. 4. Brazing: By heating the stainless steel bars and introducing a filler metal with a lower melting point, brazing creates a joint as the filler metal flows between the bars and solidifies. Brazing is a good option for joining dissimilar metals or when lower heat input is desired compared to welding. 5. Soldering: Similar to brazing, soldering uses a lower melting point filler metal to join the stainless steel bars. Soldering is typically used for lighter applications or when the bars have thinner sections, as it requires less heat input compared to other joining methods. Each joining method has its own advantages and limitations. The choice of method will depend on factors such as desired strength, appearance, and specific application requirements. It is crucial to consider these factors and seek advice from experts to determine the most suitable joining method for stainless steel bars in a given situation.

- Q:Can stainless steel bars be cut to custom lengths?

- Yes, stainless steel bars can be cut to custom lengths using different cutting techniques such as sawing, shearing, or plasma cutting.

- Q:Are stainless steel bars suitable for the brewing industry?

- Yes, stainless steel bars are suitable for the brewing industry. Stainless steel is a commonly used material in the brewing industry due to its excellent resistance to corrosion, heat, and chemicals. It is easy to clean and maintain hygiene standards, which is crucial in the brewing process. Stainless steel bars offer durability and longevity, making them ideal for use in brewing equipment such as fermentation tanks, kegs, and piping systems.

- Q:Can stainless steel bars be sandblasted?

- Yes, stainless steel bars can be sandblasted. Sandblasting is a common method used to clean and prepare the surface of stainless steel for various applications. It involves propelling abrasive materials, such as sand or fine glass beads, at high speeds onto the stainless steel surface to remove any contaminants, rust, or old coatings. Sandblasting can create a rough texture on the stainless steel, which can be desirable for certain applications, such as improving adhesion for paint or coatings. However, it is important to ensure that the sandblasting process is done correctly to avoid damaging the stainless steel bars.

- Q:What is the difference between standard and custom-sized stainless steel bars?

- The difference between standard and custom-sized stainless steel bars lies in their dimensions. Standard-sized stainless steel bars are pre-determined sizes that are readily available in the market, while custom-sized stainless steel bars are specifically manufactured to meet unique size requirements of individual projects. Custom-sized bars offer greater flexibility and can be tailored to fit precise specifications, whereas standard-sized bars are more commonly used and easily accessible.

- Q:What are the common sizes of stainless steel bars?

- The common sizes of stainless steel bars vary depending on the type and application, but some commonly available sizes include 1/8 inch, 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch, and 1 inch diameters. These sizes are often found in round bars, but stainless steel bars are also available in other shapes such as square, hexagonal, or flat bars, with varying dimensions.

- Q:Do stainless steel bars require any special handling during transportation?

- Yes, stainless steel bars typically require special handling during transportation. This is because stainless steel is prone to scratching and damage. To prevent this, it is important to handle stainless steel bars with care and avoid dragging or sliding them during transportation. Additionally, stainless steel bars should be securely packaged and protected from moisture, as exposure to water can cause staining and corrosion. It is also recommended to use appropriate lifting equipment and secure the bars properly to prevent accidents or damage during transportation. Overall, taking these precautions ensures that stainless steel bars arrive at their destination in good condition.

- Q:What are the different grades of stainless steel for bars?

- Bars commonly use several grades of stainless steel. The most frequently used grades are 304, 316, and 17-4 PH stainless steel. The most versatile and widely used grade is 304 stainless steel. It is commonly utilized in various applications, including bars, due to its excellent corrosion resistance and formability. With a minimum of 18% chromium and 8% nickel, it provides good strength and durability. Grade 316 stainless steel, often known as "marine grade" stainless steel, contains a higher amount of molybdenum. This enhances its corrosion resistance, particularly against aggressive environments like chlorides. It is frequently used in bars for applications that demand superior corrosion resistance, such as marine or chemical environments. Another frequently used grade for bars is 17-4 PH stainless steel. This grade, which can be heat treated, offers a combination of high strength and good corrosion resistance. It is suitable for applications requiring both strength and corrosion resistance, such as in aerospace or high-temperature environments. These examples represent only a few of the stainless steel grades used in bars. Each grade possesses unique properties and is selected based on specific application requirements. Factors to consider include corrosion resistance, strength, formability, and cost when choosing the appropriate grade of stainless steel for bars.

- Q:Can stainless steel bars be brushed or sandblasted?

- Yes, stainless steel bars can be brushed or sandblasted. Brushing involves using abrasive materials such as wire brushes to create a textured finish on the surface of the stainless steel bars. Sandblasting, on the other hand, utilizes high-pressure air and abrasive particles to remove any impurities or create a matte finish. Both methods can be used to enhance the aesthetics and improve the surface quality of stainless steel bars.

- Q:Are stainless steel bars suitable for pharmaceutical packaging equipment?

- Yes, stainless steel bars are suitable for pharmaceutical packaging equipment. Stainless steel is known for its corrosion resistance, strength, and hygienic properties, making it an ideal material choice for equipment used in pharmaceutical packaging. It ensures that the packaging process remains sanitary, protects the integrity of the pharmaceutical products, and complies with the stringent standards and regulations of the industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

cold rolled stainless steel round bar

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords