Stainless Angle Steel Bar ASTM 316l with Customized Surface Treatment

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ASTM 316l Stainless Angle Steel Bar

Main Structure of Angle Steel Bar

1.Surface:Bright,Polished,Turn smooth(Peeled),Brush,Mill,Pickled

2.Length:3m, 6m,9m,12m

3.Use:These products are widely supplied to areas of machine-made industry,chemical industry,spin,shipping industry,architecture,food industry,household products etc

4 ISO9001:2008

Data Information of Angle Steel Bar

Standard | AISI, ASTM, BS, DIN, GB, JIS, etc |

Grade | Q195, Q215, Q235, Q345, SS400, A36, S235JR, ST37, etc |

Technical parameters:

1) Material: Q235B , Q 345B, SS400 ,SS540, S235JR ,ETC. | |||

| 2) Usage: structure construction and electronic tower building | |||

| 3) Weight tolarance: -4% TO -10% | |||

| 4) Size tolarance : | |||

| ANGLE STEEL SIstructural steel angleE TOLARANCE (MM) | |||

| SIstructural steel angleE cm | WIDTH b/mm | THICKNESS d/mm | LENGTH /m |

| 2-5.6 | +/-0.8 | +/-0.4 | 4-12 |

| 6.3-9 | +/-1.2 | +/-0.6 | 4-12 |

| 10-14 | +/-1.8 | +/-0.7 | 4-12 |

| 16-20 | +/-2.5 | +/-1.0 | 4-12 |

| 5) Payment terms: TT or LC | |||

| 6) Delivery date: within 30 days after receiving the LC or TT prepay | |||

| 7) Packing: Export package | |||

| 8) Inspection: accept third party inspection | |||

Specification of Angle Steel Bar

1.Square bar:Size: 4mm*4mm~100mm*100mm

2.Round Bar:Diameter: 3mm~800mm

3.Angel Bar:Size: 3mm*20mm*20mm~12mm*100mm*100mm

4.Flat bar:Thickness: 2mm~100mm,Width: 10mm~500mm,

5.Hexagonal :Size: 2mm~100mm

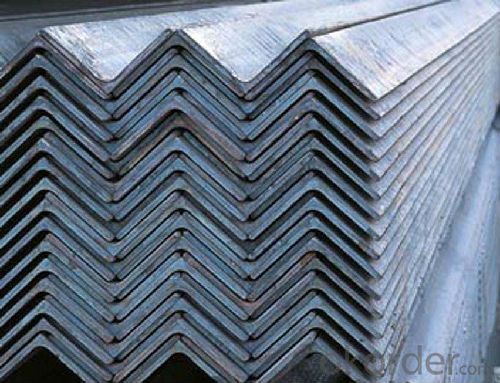

Picture

- Q:Can stainless steel angles be used in the production of construction machinery?

- Yes, stainless steel angles can be used in the production of construction machinery. Stainless steel is known for its durability, corrosion resistance, and strength, making it suitable for heavy-duty applications like construction machinery. Stainless steel angles can provide structural support and reinforcement, ensuring the durability and longevity of the machinery.

- Q:Can stainless steel angles be used in construction projects?

- It is indeed possible to utilize stainless steel angles in construction ventures. Due to its longevity and resistance to corrosion, stainless steel emerges as an outstanding option for construction purposes. In construction, stainless steel angles serve diverse functions, encompassing support for structures, framing, and fortifying buildings by contributing extra strength and stability. They find widespread employment in commercial and industrial projects, where robustness and durability hold immense importance. Furthermore, stainless steel angles come in a range of sizes and shapes, providing flexibility in both design and construction.

- Q:What are the fatigue properties of stainless steel angle?

- The fatigue properties of stainless steel angle refer to its ability to withstand repeated cyclic loading without experiencing failure or deformation. Stainless steel angle is known for its high strength and excellent corrosion resistance, making it suitable for various applications in structural and engineering industries. Stainless steel typically exhibits good fatigue properties due to its unique microstructure and composition. The presence of chromium in stainless steel enhances its corrosion resistance, while other alloying elements like nickel and molybdenum improve its strength and fatigue resistance. The fatigue strength of stainless steel angle depends on various factors, including the specific grade of stainless steel, surface condition, loading conditions, and environmental factors. Stainless steel angles with higher alloy content, such as duplex or precipitation-hardening grades, tend to have superior fatigue properties compared to standard austenitic stainless steels. The fatigue behavior of stainless steel angle is commonly assessed through fatigue testing, which involves subjecting the material to cyclic loading until failure. These tests provide valuable information about the stress-life (S-N) curve, which represents the relationship between applied stress amplitude and the number of cycles to failure. Stainless steel angle is often used in structural applications where fatigue resistance is critical, such as bridges, offshore platforms, and industrial machinery. Engineers and designers consider the fatigue properties of stainless steel angle to ensure the structural integrity and durability of these applications under cyclic loading conditions. Overall, stainless steel angle exhibits good fatigue properties, making it a reliable and durable material for various structural and engineering applications. However, it is essential to consider the specific grade, loading conditions, and environmental factors to accurately assess and optimize its fatigue performance.

- Q:Can stainless steel angles be used for shelving?

- Indeed, shelving can make use of stainless steel angles. Stainless steel, renowned for its durability and resistance to corrosion, finds widespread application, notably in shelving systems. Stainless steel angles contribute to the stability and structural support necessary for heavy-duty shelving. Their installation is hassle-free, and they exhibit a sleek and contemporary aesthetic. Furthermore, stainless steel can be effortlessly cleaned and maintained, rendering it an ideal selection for shelving in places demanding strict hygiene standards, such as kitchens, hospitals, or laboratories.

- Q:What is the difference between 304L and 304H stainless steel angles?

- The difference between 304L and 304H stainless steel angles lies in their carbon content. 304L stainless steel angles have a lower carbon content compared to 304H stainless steel angles. This difference in carbon content results in different mechanical and chemical properties of the two grades. 304L stainless steel angles are known for their excellent corrosion resistance and are often used in environments where exposure to corrosive substances is a concern. The lower carbon content reduces the susceptibility to sensitization, which is the formation of chromium carbides at grain boundaries. This makes 304L stainless steel angles resistant to intergranular corrosion and suitable for applications in the as-welded condition. On the other hand, 304H stainless steel angles have a higher carbon content, which provides increased strength at elevated temperatures. This makes 304H stainless steel angles suitable for high-temperature applications such as heat exchangers, furnace parts, and boiler components. However, the higher carbon content also makes 304H stainless steel angles more prone to sensitization and intergranular corrosion. Therefore, proper heat treatment and post-weld annealing are necessary to mitigate these issues. In summary, the difference between 304L and 304H stainless steel angles lies in their carbon content, which affects their corrosion resistance, strength at elevated temperatures, and susceptibility to sensitization and intergranular corrosion. The choice between the two grades depends on the specific requirements of the application.

- Q:What are the common industries that use stainless steel angles?

- Due to their versatile properties and durability, stainless steel angles are used in a wide range of industries. In construction, they are commonly used for structural purposes, providing support and reinforcement in various building components such as beams, columns, and frames. Their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme weather conditions make them an ideal choice for construction projects. Architects often incorporate stainless steel angles into their designs for aesthetic purposes. These angles can be used for decorative trims, handrails, and balustrades, adding a modern and sleek look to buildings. Stainless steel angles offer a clean and polished appearance, making them popular in architectural applications. In manufacturing industries, particularly those involved in machinery and equipment production, stainless steel angles are relied upon. They are commonly used in the fabrication of conveyor systems, platforms, and industrial equipment. The corrosion resistance and robustness of stainless steel angles make them suitable for harsh and demanding manufacturing environments. The transportation industry, including the automotive, aerospace, and marine sectors, often integrates stainless steel angles into their designs. These angles are utilized for manufacturing vehicle frames, shipbuilding components, and aircraft structures. The high strength and corrosion resistance of stainless steel angles make them reliable and long-lasting solutions in the transportation sector. Overall, due to their exceptional properties, stainless steel angles are widely employed in the construction, architecture, manufacturing, and transportation industries. Their versatility, strength, and resistance to corrosion make them an ideal choice for various applications across different sectors.

- Q:What is the density of stainless steel angles?

- The density of stainless steel angles typically ranges from 7.9 to 8.0 grams per cubic centimeter.

- Q:What is the difference between 304 and 316 stainless steel angles?

- The composition and presence of certain elements differentiate 304 and 316 stainless steel angles. 304 stainless steel, a versatile and widely used alloy, contains chromium and nickel. It is recognized for its excellent corrosion resistance, durability, and ease of fabrication. However, 304 stainless steel angles are less resistant to corrosion in specific environments, like marine or highly corrosive settings, compared to 316 stainless steel angles. On the contrary, 316 stainless steel angles are a higher grade alloy with additional elements like molybdenum, enhancing their corrosion resistance. This makes them well-suited for applications expecting exposure to chloride-based substances, acids, or high salinity. Marine environments, chemical processing plants, and medical equipment commonly employ 316 stainless steel angles. Regarding appearance, both 304 and 316 stainless steel angles possess a similar look and finish. However, due to the presence of additional elements, 316 stainless steel angles may exhibit a slightly higher luster. In summary, while both 304 and 316 stainless steel angles offer good corrosion resistance and durability, 316 stainless steel angles are better suited for applications requiring higher levels of corrosion and pitting resistance, especially in harsh or corrosive environments.

- Q:Can stainless steel angles be used in food processing applications?

- Yes, stainless steel angles can be used in food processing applications. Stainless steel is commonly used in the food industry due to its excellent corrosion resistance, hygienic properties, and durability. Stainless steel angles are particularly useful in food processing as they can be easily fabricated and installed to create structural frameworks, equipment supports, and sanitary surfaces. The smooth and non-porous surface of stainless steel angles prevents the accumulation of dirt, bacteria, and other contaminants, making them ideal for use in food processing facilities where cleanliness and hygiene are of utmost importance. Additionally, stainless steel angles are capable of withstanding high temperatures, heavy loads, and harsh cleaning agents, making them suitable for a wide range of food processing applications such as conveyor systems, cutting tables, and storage racks.

- Q:What are the common applications of stainless steel angles?

- Stainless steel angles are commonly used in various applications such as construction, architecture, machinery, transportation, and manufacturing industries. They are widely used for structural support, framing, reinforcement, and bracing in buildings, bridges, and infrastructure projects. Additionally, stainless steel angles find application in the production of machinery and equipment, as well as in the fabrication of automotive parts and components. Their corrosion resistance, strength, and versatility make them an ideal choice for numerous industrial and commercial applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Angle Steel Bar ASTM 316l with Customized Surface Treatment

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords