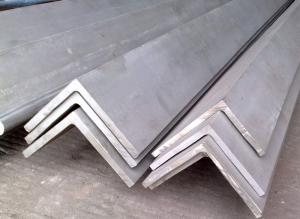

Best Quality for Stainless Steel Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2MT m.t.

- Supply Capability:

- 5000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Details of Stainless Steel Angle:

Size mm | |

Width | Thickness |

25 x 25 | 3 4 5 |

30 x 30 | 3 4 5 |

40 x 40 | 3 4 5 6 |

50 x 50 | 4 5 6 |

60 x 60 | 5 6 7 |

65 x 65 | 5 6 7 |

70 x 70 | 6 7 8 |

75 x 75 | 6 7 8 9 |

80 x 80 | 7 8 9 10 |

100 x 100 | 8 9 10 12 |

Tolerance:GB4227, ASTM A276/A 484M, EN10056/DIN 1028 | |

Features of Stainless Steel Angle:

1. All products are made of high-quality imported raw materials.

2. Our products are certified by ISO9001:2008 authentication quality systems.

3. We are nominated as the AAA enterprise by Jiangsu government.

4. Quickest and most efficient Response to Your Enquiry.

5.Selected quality material

6.Finely processed

7.Prime quality&Bottom price

8.Complete in specifications

9.Abundant stock

Application of Stainless Steel Angle

Stainless steels of various kinds are used in thousands of applications. The following gives a flavour of the full range:

1.Domestic --- cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2.Architectural/Civil Engineering---- cladding, handrails, door and window fittings, street furniture, structural sections,reinforcement bar, lighting columns, lintels, masonry supports

3.Transport --- exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

4.Chemical/Pharmaceutical --- pressure vessels, process piping.

5.Oil and Gas ---platform accommodation, cable trays, subsea pipelines.

6.Medical ---Surgical instruments, surgical implants, MRI scanners.

7.Food and Drink ---Catering equipment, brewing, distilling, food processing.

8.Water ---Water and sewage treatment, water tubing, hot water tanks.

9.General ----springs, fasteners (bolts, nuts and washers), wire.

- Q:Can stainless steel angles withstand extreme weather conditions?

- Yes, stainless steel angles can withstand extreme weather conditions. Stainless steel is highly resistant to corrosion and oxidation, making it durable and suitable for outdoor applications. It can withstand high temperatures, heavy rainfall, and exposure to UV rays without losing its strength or appearance.

- Q:Can stainless steel angles be used in bridge construction?

- Bridge construction can utilize stainless steel angles effectively. Stainless steel is a durable and versatile material that offers exceptional resistance to corrosion, impressive strength, and low maintenance requirements. These qualities make stainless steel angles appropriate for a wide range of applications, including bridges. In bridge construction, stainless steel angles find frequent use for different purposes. They can serve as reinforcement in concrete bridges, augmenting their strength and stability. Stainless steel angles can also fulfill structural needs by supporting beams and columns. Additionally, they contribute to the aesthetic appeal of bridges, adding a modern and sleek touch to their designs. One of the significant advantages of incorporating stainless steel angles into bridge construction is their resistance to corrosion. Bridges face various environmental conditions, including moisture, humidity, and chemicals, which can corrode traditional construction materials. However, stainless steel angles exhibit high resistance to corrosion, ensuring the long-term structural integrity of the bridge. Moreover, stainless steel angles offer a high strength-to-weight ratio, which benefits bridge construction. This means that stainless steel angles can provide the required strength while minimizing the weight of the bridge structure. This advantage becomes particularly important for large-scale bridges, where reducing weight can lead to cost savings and improved performance. In conclusion, stainless steel angles are a suitable choice for bridge construction due to their corrosion resistance, high strength, and aesthetic appeal. Their versatility and durability make them appropriate for various structural and reinforcement applications in bridges.

- Q:Can stainless steel angles be used in the production of power transmission equipment?

- Yes, stainless steel angles can be used in the production of power transmission equipment. Stainless steel is known for its high strength, corrosion resistance, and durability, making it a suitable material for various industrial applications, including power transmission equipment. Stainless steel angles can provide structural support, enhance stability, and withstand the demanding operating conditions of power transmission systems.

- Q:What is the difference between hot rolled and cold rolled stainless steel angles?

- The main difference between hot rolled and cold rolled stainless steel angles lies in the production process and the resulting properties. Hot rolled stainless steel angles are produced by heating a steel billet or ingot above its recrystallization temperature and then shaping it into the desired angle shape. This process allows for a larger range of sizes and shapes to be produced, making hot rolled angles more versatile. The high temperature during production also leads to a rougher surface finish and a scaled appearance on the outer surface, which may require additional surface treatments to achieve a desired aesthetic. On the other hand, cold rolled stainless steel angles are produced by passing the hot rolled angles through a series of rollers at room temperature. This process results in a smoother surface finish and tighter dimensional tolerances compared to hot rolled angles. The cold rolling process also increases the strength and hardness of the stainless steel angles, making them more ideal for applications that require high strength and precision. In terms of properties, hot rolled stainless steel angles typically have a larger grain structure due to the high temperature involved in the production process. This can lead to reduced corrosion resistance and mechanical properties compared to cold rolled angles. Cold rolled angles, on the other hand, have a finer grain structure resulting in improved mechanical properties and better resistance to corrosion. In summary, the main differences between hot rolled and cold rolled stainless steel angles lie in the production process, surface finish, dimensional tolerances, strength, hardness, and corrosion resistance. The choice between the two depends on the specific application requirements and desired properties.

- Q:Are stainless steel angles suitable for manufacturing tanks?

- Yes, stainless steel angles are suitable for manufacturing tanks due to their high strength, corrosion resistance, and durability.

- Q:What is the wear resistance of stainless steel angles?

- Stainless steel angles have excellent wear resistance due to their high levels of chromium and nickel content, which form a protective oxide layer that prevents corrosion and reduces mechanical wear and tear.

- Q:What are the different manufacturing standards for stainless steel angles?

- There are several manufacturing standards for stainless steel angles, including ASTM A276, ASTM A484, and ASTM A582. These standards specify the chemical composition, mechanical properties, and tolerances for dimensions and surface finish of stainless steel angles. These standards ensure quality and consistency in the manufacturing process and facilitate the use of stainless steel angles in various applications.

- Q:How do you calculate the moment of resistance for a perforated stainless steel angle?

- To calculate the moment of resistance for a perforated stainless steel angle, you need to consider the geometry and material properties of the angle. First, determine the cross-sectional properties of the perforated stainless steel angle. This includes the dimensions of the angle (width, height, and thickness) and the location and size of the perforations. You will also need to know the yield strength of the stainless steel material. Next, calculate the section modulus (Z) of the angle. The section modulus is a measure of a section's resistance to bending and can be calculated by multiplying the moment of inertia (I) of the section by the distance from the centroid of the section to the extreme fiber. The moment of inertia can be determined using standard formulas for a perforated angle or by using specialized computer software. Once you have the section modulus, you can calculate the moment of resistance (M) using the formula M = Z * fy, where fy is the yield strength of the stainless steel material. This formula assumes that the angle is subjected to pure bending and that the material is in the elastic range. It is important to note that the moment of resistance calculated using this method provides an estimate of the angle's capacity to resist bending. However, the actual moment of resistance may be affected by additional factors such as the type of perforation, the presence of welds or other connections, and the overall structural system in which the angle is being used. Therefore, it is always recommended to consult relevant design codes and standards or seek professional engineering advice when designing structures involving perforated stainless steel angles.

- Q:Can stainless steel angles be hot-dip galvanized?

- No, stainless steel angles cannot be hot-dip galvanized. Hot-dip galvanizing is a process used to coat steel with a layer of zinc, but stainless steel is already corrosion-resistant due to its high content of chromium.

- Q:What are the different types of machining processes used with stainless steel angles?

- There are several different types of machining processes that can be used with stainless steel angles. Some of the most common ones include: 1. Cutting: This process involves the removal of material from the stainless steel angle to achieve the desired shape or size. It can be done using various tools such as saws, shears, or plasma cutters. 2. Drilling: Drilling is the process of creating holes in the stainless steel angle. It can be done using drill bits specifically designed for stainless steel or using a CNC machine for precision drilling. 3. Grinding: Grinding is used to smooth the surface of the stainless steel angle or to remove any burrs or sharp edges. It involves the use of abrasive wheels or belts that rotate against the angle to achieve the desired finish. 4. Milling: Milling is a machining process that uses rotary cutters to remove material from the stainless steel angle. It can be used to create complex shapes or to achieve a specific surface finish. 5. Welding: Welding is a process that joins two or more stainless steel angles together by melting the edges and allowing them to fuse. It is commonly used in fabrication processes to create larger structures or assemblies. 6. Bending: Bending is the process of deforming the stainless steel angle to a specific angle or shape. It can be done using specialized tools such as press brakes or by using heat to soften the metal and then bending it manually. Each of these machining processes has its own advantages and limitations, and the choice of which process to use depends on factors such as the desired outcome, the complexity of the project, and the available equipment and resources.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for Stainless Steel Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2MT m.t.

- Supply Capability:

- 5000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords