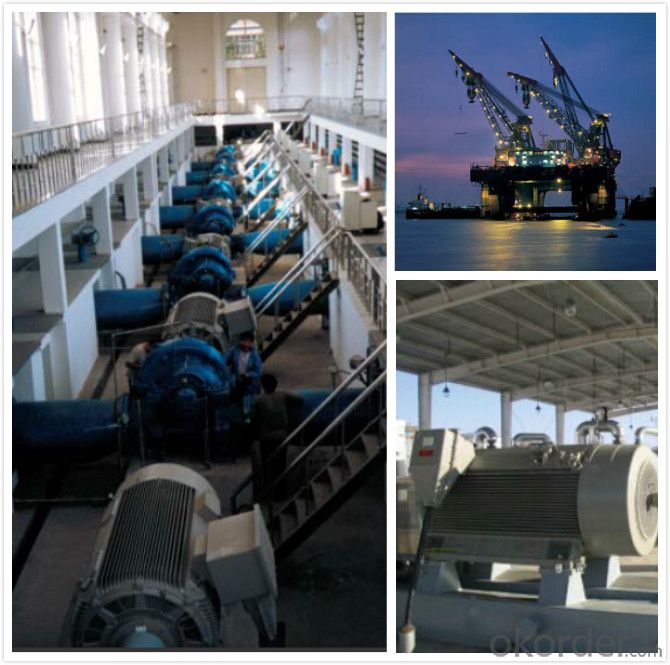

Siemens ILE0001 Series High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| part name | brand | model | Voltage | protection | cooling | |

| motor | Siemens | 1LA8 | 1PQ8 | 400V,690V,2.3KV,4.16KV,6KV | IP55 | IC411 (1LA8,1LA4) |

| IC416 (1PQ8,1PQ4) | ||||||

- Q:Structure of alternating current motor

- AC motor:Single phase motors are mainly divided into series excited motors, such as hand drills, vacuum cleaners, household food processors...... Induction motors generally use capacitive phase shifters, such as fans, air conditioners, and refrigerator compressors...... Used motor. ?The three-phase motor is mainly divided into three phase synchronous motor and three-phase asynchronous motor.

- Q:i need help with a school project. im in high school.

- An electric motor has a rotating armature, and stationary field magnets. The armature's magnets are usually electromagnets, and the field magnets are usually electromagnets in large motors, or permanent magnets in small motors. Whether it's an AC or DC motor, the rotation comes from the interaction of the armature with the field magnets, either attracting or repelling each other. It takes a very intense magnetic field to produce the forces that rotate the motor, and the magnets within the motor are designed to direct the fields so that they can interact strongly. Magnetic fields' intensity varies inversely with the square of distance from the magnet. That means if you move 2x as far from a magnet the intensity drops to 1/4 and if you move 3x as far from a magnet its intensity drops to 1/9. This means that for the motor to be powerful, its magnets must not only be strong, but very close to each other as well. So, what about an outside magnetic field? Will it affect the motor? Yes, it will, but the real question is - how much? Most magnetic fields in our world are not very strong, and not anywhere near as strong as those found inside a motor. In addition, the source of an outside magnetic field is going to be much farther away from the motor than the motor's magnets are from each other. Finally, most practical motors are enclosed in a metal frame that blocks magnetic fields from getting in or out. As a practical matter, a normal outside magnetic field would be too feeble in comparison with the motor's own fields to affect a normal motor. To have a noticeable interaction would require an exceptionally strong outside field, and a very small motor.

- Q:Please tell advantages disadvantages of both?

- AC okorder /

- Q:after changing the brushes on my wood router with a ac motor it is not working and both wires are live

- Sounds like you have a broken connection on the neutral side, maybe a loose wire in the mains plug ? That will give a live reading on the neutral side of the motor.

- Q:AC motor stator winding does not turn, why the back EMF?

- Back EMF is the electromotive force in the opposite direction of the electromotive force of the power supply. EMF may occur when there are multiple power supplies in the circuit. For example, the two metal bars on the same rail circuit cut the magnetic field at different speeds, and there may be a counter electromotive force; the electromotive force and the induced electromotive force exist simultaneously, and the back EMF may occur. For the coil, when the current of the winding changes, both ends of the coil will generate back electromotive force. For example, in the LC oscillating circuit, the change of the voltage at the two ends of the inductance coil is closely related to the counter electromotive force. When the motor coil turns, the back EMF is also generated.

- Q:If the current is 45 amperes under this condition, calculate the power factor, reactive power, and reactive kilovolt-amperes

- If it is a 3-phase motor, the power factor is 0.49 calculated as shown in another answer. That is a rather low power factor, but not unreasonable, particularly if it is a low speed motor or is lightly loaded. If it is a single phase motor, the kva is simply 45 X 230 / 1000 = 10.35 and the power factor is 8.8 / 10.35 = 0.85. Assuming that it is a standard motor operating at full load, it is most likely a 7.5 kW (10 Hp) motor. In that case the efficiency would be 7.5/8.8 X 100 = 85.2%, a reasonable figure for that size motor. It would be unusual for a motor of that size to be a single phase motor, but single phase motors of that size are listed in some motor catalogs.

- Q:Okay well first off our ac was running awesome and then one day the unit stopped spinning outside so we called a professional he came out and said that the capacitator(not sure how to spell it) burnt up which was not uncommon in this heat then he said we needed to change our filters he hosed it all down recharged the freon, a week later it compeltely freezes up, the outside unit was spinning but nothing was coming out of the vents , so we let it thaw out call him he comes out says our blower motor was getting stuck so he readjusted it said it was working already cooling our house down! Awesome except it froze up again! So we call him again and he tells us that our blower motor in our furnace needed replaced, so we replaced that ... We fall asleep to a hot house hoping it would get cooler threw the night w our running ac again only to wake up to it being frozen again ..... Please help ...

- You AC guy, like most others I've run across, has absolutely no idea what's wrong with your system. They are taught in AC school that if this happens, replace that. If that happens, replace this. They are not taught HOW TO TROUBLESHOOT! I've had so called AC techs try to tell me that the motor will cause the capacitor to fail or the capacitor will cause the motor to fail. I've been in electronics for 43 years. It will not. A failed capacitor will prevent the motor from starting or running. Sure, he replaced the capacitor because the motor stopped running - it's a run capacitor needed for the motor. That was the easy part. Cleaning the coils by hosing them down is a maintenance action, not a repair action, unless it was extremely clogged with dirt. I doubt the blower motor was getting stuck and needed adjusting. There is no adjustments for AC motors. If the motor was bad, he should have caught that on the 1st visit. You may have bought a motor you didn't need. He's cleaned the coils and recharged the system (which I doubt was he problem either). I'm not an AC tech, but I believe you have a restriction in the refrigerant line going to the evaporator. That restriction is acting like the expansion valve causing the evaporator to ice up. A plugged or severely restricted expansion valve itself may be the problem. That's what the problem was with my unit. The restriction could also be a kinked refrigerant line going to the evaporator - that was the problem with my daughter's unit. IT'S NOT YOUR COMPRESSOR. The fact that you can create ice tells me the compressor is working. But if the problem isn't fixed soon, you could lose the compressor due to high head pressures caused by the icing problem.

- Q:lionel trains

- I am not understanding your question; Lionel Trains normally use reversible universal motors and are run on AC.

- Q:Their advantages,disadvantages comparison table?

- V/f control is simply the control of the voltage and frequency applied to an AC motor such that the relationship between voltage and frequency is that the ratio of voltage to frequency is a constant. V/f control is often enhanced by adding “boost,” increasing the V/f ratio at the low end of the frequency range. V/f control would not be considered to be torque control although some protective torque limiting method is often included. Control methods that emulate the armature current regulation control strategy of a DC motor are called flux vector control, field orientation control, or direct torque control. These control strategies mathematically model the motor and estimate its performance by measuring the motor current and the instantaneous vector relationship between the applied voltage and the current. A motor shaft speed and position sensor may be used to determine the instantaneous rotor speed and position. Vector control systems are often called “sensorless vector” when a shaft speed and position sensor is not used. Vector control can provide torque control that allows a torque reference to be set and the delivered torque to be held at the set value with the motor being determined by the torque delivered and the characteristics of the load as long as the drive is within rated limits. The details of the control implementation are generally not fully disclosed by the manufacturers. Since drive performance is affected by the characteristics of the load, manufacturers do not generally provide specific performance information. However, there is a lot of application information available form drive manufacturers. Detailed technical papers are published by the IEEE, but it not always possible to determine which products, if any, implement techniques discussed in IEEE papers.

- Q:i need to conttrol the speed on a 24 volt dc motor and i want to use a 120 volt ac dimmer switcth

- you need a 120V ac to 24V dc transformer connect the dimmer switch to the transformer power IN supply, why you want to do this is another Q ;/

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Siemens ILE0001 Series High Low Voltage AC Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords