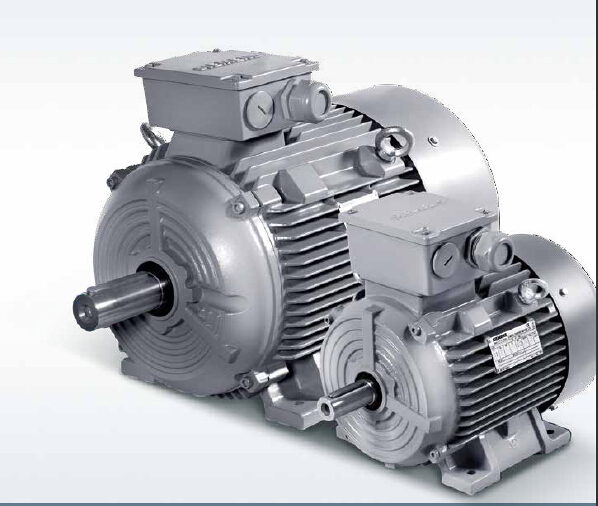

Siemens ILG Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Is switch bad on my pickup if, the acurator motor is not opening the heater box door for inside when max ac?

- Is this an early model Chevrolet in the 1990's? If it is there is a link on the motor actuator, under the dash, that has fallen off. When it falls off you will have either full defrost with no max. ac from the dash, or you will have max ac from the dash with no defrost. Get upside down under your dash with a small flashlight so you can get your head in there to find it. If this is the case it will go right back on. It is located up under the dash just to the right of the steering column. Good luck.

- Q:Can anyone give me the torque equations for AC synchronous motor and generator

- Torque=Kt*I, where Kt is the torque constant and I is the current. It's that simple.

- Q:again after it sits 3 to 4 hours. What could be causing this?

- sounds like its over heating somehow but i wouldnt really know which directiong to point you in as far as fixing the problem..sorry

- Q:is it jus possible by altering d electrical connections

- Maybe. It depends on the rotor. If the rotor is made of permenant magnets, simply rotating it will turn the motor into a dynamo and create electrical energy. However, many motors rely on electricity to create magnetic fields around the rotor, so there is going to have to be some feedback from the output back into the rotor circuit to generate the fields. However, this energy is going to be responcible for creating the output in the first place. Therefore, this would be an impossible design, since it would be essentially a perpetual motion machine. The electricity supplying the rotor coils would have to be input from an independant circuit. Perhaps linking a magnet driven electric motor to the rotor of the coil driven motor would work, but it would be highly inefficient unless the system was balanced precisely in terms of the energy flowing between the coil and the magnet based dynamo. Another approach might be to use solar cells to drive the rotor coils. I don't have any idea of how efficient this might be, but I suspect it is going to take fairly large sized cells to drive the rotor windings. Of course one last thing to concider is the fact dynamos and solar cells generate direct current. Most coil driven rotors operate off alternating current. The DC current would have to be transformed into AC current at 60 cycles per second at a voltage sufficient to drive the coils. DC to AC circuits are easy to build and if one can manage to generate 60 cycles per second, the construction of the coils on the rotor will take care of the rest. 60 CPS (cycles/second) is a universal design in power grids, and electric motors are designed around this standard.

- Q:The difference and advantage between DC motor and AC motor

- DC motor:Advantages: 1., you can achieve a smooth and economical speed adjustment;2. does not require the coordination of other equipment, as long as the input or excitation voltage, current

- Q:Is this the part that controls wether i get cold or hot air? Please give lots of detail about the location of this part.Thanks

- Yes it controls the blend door inside the plynum so its called a blend door acuator.Its either a acuator motor or vacuum controled diaphram thats located in the plynum,basically the giant plastic box mounted inbetween the dash and fire wall near the heater core.Would have to rip up the dash to get to,and would be a good idea to get a chiltons or take it into a shop, its a big job..GL

- Q:Soooo... my outside condensor fan has started making this LOUD squealing noise... its like the noise you hear sometimes when it starts up... but it doesn't stop, and gets louder and Louder..like grinding metal.. and it only happens in the winter time when it gets below 45 degrees (F) or so... it works perfectly fine in the summer... The fan spins good and come on fine.. its just the noise..... So what i'm trying to figure out is ... is it the Motor.... or the Fan blades... because the motor is spinning the blades just fine...and with my research i found that when bad fan blades get wet they make a squealing noise..so i thought maybe the same applys with the cold...... or is it the motor with some bad barrings or something... any help??...thanks

- First of all, your AC condensor outside should only have the fan come on when the AC is on, not when the heat is on, so why would it be coming on when it is below 45F? Usually the fan is mounted on and directly driven by the motor. Fan blades do not usually make a squealing noise when wet. Most likely the bearings have ran dry and at the very least need lubed. That it's been allowed to run like this for a while (presumably), the bearing may have worn enough that the whole motor needs replaced. Many fans today are considered permanently lubed but that is nonsense, they just don't put a lube hole in to save money and make people buy a new motor sooner. They just need pulled out, the through-bolts removed, and disassembled like this until you have access to the bearings or the felt oil reservoir rings to add a few (several, depending on the motor size) drops of oil. Standard 20wt motor oil, or even 5W20, 5W30, 10W30, etc will do in a pinch. If you have a legitimate need to run the A/C in the winter at 45F which I questioned above, then go with one of the thinner oils like 5W20. The only time the blades should/would squeal is if the nut that secures it to the motor shaft is loose and so the blade assembly is wobbling around.

- Q:working of stator ,rotar.

- Most AC motors are induction motors. They contain some stationary coils of wire called the stator. The stator is connected to an AC power source and AC current flows through the stator coils. The current in the stator creates a magnetic field that rotates at a speed that is determined by the frequency of the alternating current. The rotating part of the motor, the rotor, contains electrical conductors, usually aluminum bars that are connected together. The rotating magnetic field of the stator passes through these conductors and causes an alternating current to flow in the rotor. The rotor current creates another magnetic field. That magnetic field is attracted to the rotating stator magnetic field. The force of that magnetic attraction, moves the rotor and causes it to rotate at a speed that is only sightly slower than the speed of the stator field.

- Q:I have a 220v motor stripped from a hair dryer that looks like a DC. How can I differentiate (visually or through tests) a DC motor from a AC / DC (universal) motor?

- DC MOTORS ARE NOT 220V. It uses your wall without a large converter box that gets warm, so there isn't DC conversion. DC motors are usually 24 volts and under.

- Q:other?

- Some of the largest AC motors are pumped-storage hydroelectricity generators that are operated as synchronous motors to pump water to a reservoir at a higher elevation for later use to generate electricity using the same machinery. Six 350-megawatt generators are installed in the Bath County Pumped Storage Station in Warm Springs, VA USA. When pumping, each unit can produce 563,400 horsepower (420,127 kilowatts).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Siemens ILG Series Motor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords