Shock Absorber - Isolation Block The Elastic Modulus And The Shear Modulus Is Low

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Rubber:

Natural rubber is a kind of polyisoprene as the main component of natural high molecular compound, its composition in 91% ~ 94% is the rubber hydrocarbon(polyisoprene), the protein, fatty acid, carbohydrate, ash and other non rubber substance. Natural rubber is the most widely used general rubber..

2. Main features of Oil Seal:

1) High Elasticity, According To The Formula, The Elastic Can Reach 80% Of The Maximum.

2) High Elongation, The Maximum Can Reach More Than 1000%.

3) The Elastic Modulus And The Shear Modulus Is Low, Than Some Rigid Substances Such As Iron And Steel And Other Low Much.

4) Cold Resistant, The Glass Transition Temperature Of Minus 72 Degrees

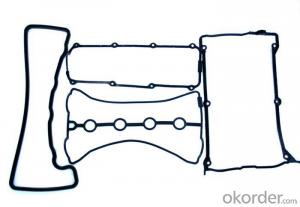

3. Rubber Images:

4. Rubber Application:

Rubber elasticity, good insulation, impermeability and plasticity characteristics of natural rubber, and through the mix after appropriate treatment also has oil resistance, acid and alkali resistance, heat resistance, cold resistance, pressure resistance, wear resistance and other properties, therefore, has the widespread use, mainly used for automobile, machinery, industrial etc. industry as a shock, sealing parts.

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Rubber is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:I need to replace the left front axle of my 99 sentra and I'd like to know if the strut needs to be removed?, my brother in law is going to help me, he's done it before to his cars and the last time didn't aligned correctly or something and when the mechanic changed his transmission he removed both axles and transmission without removing the struts plus I've seen on youtube that a mechanic didn't remove the struts to replace it, Can it be done without messing with the strut.

- Only if you know how to do it without removing the strut

- Q:just wondering what axles came in truck? Front and rear combinations?

- For the best answers, search on this site shorturl.im/axPLw Huh your kidding Toyo are Junk,Bf Goodrich,Michelin, Goodyear are great American made tires and Yokohama are trash too

- Q:I‘m looking to get at least 35 in. tires but I know it will be hard on the trans and it will go slow so I have to re-gear the axles but I was wondering how much that costs

- We need to know the exact year make and model of your car. I've never heard of re-gearing axles. Unless you've added a ton of horsepower the axles themselves wouldn't be affected. Usually the ring and pinion gears are the first to suffer. 35 tall wheels and tires wouldn't fit under a lifted pick up truck! Depending on which rear third member you plan to use the axles have splines on the inside of the center section on a machine with a hobbing cutter. Full floating rear ends such as a racing Ford 9 rear has splines on both ends of each axle.

- Q:im looking for a project car and ive found an infiniti g35 coupe that has a crashed axle, how much would it be or could i even fix it myself? how much would it be if i took it to a mechanic?

- if ur in the dallas area i

- Q:does anyone have any idea on how to prevent bad axles!?? NEED help thanks!!!

- The best way to prevent damage to any part of your car is drive very gently. Harsh stop and go driving with heavy use of the throttle and brakes stresses everything more than it's designed to withstand. Harsh acceleration with the wheels turned sharply is especially bad for drive axles.

- Q:Do you measure from the bottom of the stud plate or the top of the stud plate? To the top of the splines or to the tip of the axle where the c-clip goes on (which is just past the splines).

- If you are replacing the original axle with a stock part, then use the part number-that is the best way to get the correct axle. If you are purchasing from an after market company, they will want to know the year and make of the housing, as you know, there are small differences, due to the track of the various years and vehicles, and each maker has a different way to measure. For example, the 66 through 67 chevelle 12 bolt is about 1.5 inches more narrow than the later models. But If you are trying to junkyard a 12 bolt, a tried and true American hot rodding tradition, then you measure from the tip of the axle spline side to the outside of the stud plate. And remember, check for interchangeable parts with the Howard guide, not all 12 bolts will interchange.

- Q:can you use a full spool on the streets if you have a manaul 4x4 axle in the front

- Absolutely not! If you had a spool inside the front differential you'd eat-up your new set of tires in less than 500 miles. You'd tear the axles right out of the front center-section to boot.The front tires would squeal and jump all over the place as you steer less than 5 mph. If you bought rock-hard rear tires for a rear locked differential, they'd be gone in 1,000 miles. You'd never be able to turn sharp corners on black-top. If you had a custom built third member with short axles rear tire life would be a bit more. Black-top modified race cars have full spools in the rear but the left rear tire has 2 1/2 - 3 inches less circumference to help the car steer left all the time. The larger the track with sweeping corners the less tire stagger you need. Tires last one to two nights of racing.

- Q:I cant believe I‘m asking this, but what the heck. My wife just wrecked her 2002 Suzuki XL-7 (someone hit her on the driver front). Her camber was very negative, I automatically notice and knew to replace the strut due it being bent. Replaced that in less then 20 minutes, but there is still a slight negative in camber. I had the SUV jacked up and did the left and right tire shake and the up and down tire shake. Up and down had no free play but the left and right had a very slight free play. But the tie rods have nothing to deal with camber. The SUV has no upper control arm, so the only opponent left that I could imagine effecting camber is the axle at this point, am I right or wrong?

- No. It does have an upper control arm - the strut its self. There should be no movement if the tire is grabbed at the top and bottom and push in and out. It probably will move if you grab the front and back and push in/out and that is fine. The other component you didn't mention. The lower control arm. It may be bent. Some light reading: THE MACPHERSON STRUT Earle MacPherson confronted both of these limitations when designing the Cadet in the mid-forties. The Cadet's track width was only about 48 inches (122 cm) -- fully a foot (30 cm) narrower than the track width of a contemporary full-size Chevrolet -- which didn't leave a lot of space for suspension components. Furthermore, the ambitious price target meant that the cost had to be reduced as much as possible. Beam axles would have been easier, but they would not have provided acceptable ride or handling, particularly considering the Cadet's low sprung mass. MacPherson's strategy was essentially to simplify the unequal-length control arm layout. The Cadet's suspension retained the lower control arm, which was actually formed by a relatively narrow transverse arm and a skinny, diagonal radius rod. Instead of an upper control arm, however, the wheel spindle was mounted on a vertical strut, mounted rigidly to the body. The strut incorporated a tubular shock absorber, and it served both as the upper control arm and as the axis around which the front wheels were steered. The coil spring was mounted over the upper part of the strut, near where it attached to the body; this saved space, and allowed the lower control arm to be thinner, since it didn't have to handle the loads generated by the springs.

- Q:how do you get axle rpm?

- they work great,they are not a cure for mechanical breakdown but do offer more protection.lucas was originally designed for heavy truck use. i have used these products for many years and never had a problem. as for cold starts the lucas stays on the parts to protect them till oil gets to them. as an example at 20 below 10w30 can take up to 3 minutes to lube the top end were as 5w30 takes less than a minute,this time period is where lucas adds protection

- Q:I have a 2002 wrangler tj and I heard that on some older jeeps you could get 2-3 of lift just by flipping the axles. Is this true and if so, about how much would this cost me?

- No you cant you have coil springs that are already mounted ontop of the axles. FLIPPING the axles refers to a leaf sprung vehicle where the leaf springs are mounted under neath the axle, by moving the above the axle you gain 3-4 of lift and increase axle wrap. This can not be done with a coil sprung vehicle.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Shock Absorber - Isolation Block The Elastic Modulus And The Shear Modulus Is Low

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords