Seamless Steel Tube And Pipe For Gas Cylinder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications of Seamless Steel Tube And Pipe For Gas Cylinder

Wide Range of Size: from 60mm to 559mm

Flexible MOQ: 4 ton/per size

Product: Seamless Steel Pipe for Gas Cylinder

1. Size Range:

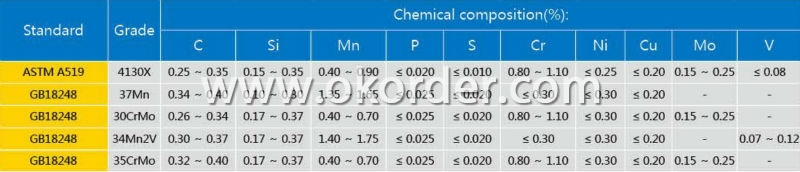

2. Chemical Copmosition(%):

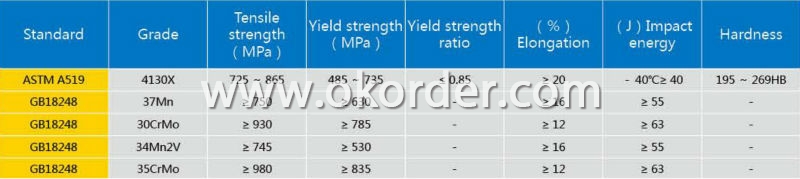

3. Mechanical Properties:

4. Tolerances on Demisions:

Packaging/Delivery of Seamless Steel Tube And Pipe For Gas Cylinder

Wrapped in bundles with steel strips or according to customers' requirements

- Q:Can steel pipes be used for underground water wells?

- Yes, steel pipes can be used for underground water wells. Steel pipes are commonly used for drilling water wells due to their durability, strength, and resistance to corrosion. However, it is important to ensure that the steel pipes are properly coated and protected to prevent any contamination of the underground water source.

- Q:What are the different methods of protecting steel pipes from external damage?

- There are several methods of protecting steel pipes from external damage, including coating the pipes with a corrosion-resistant material such as epoxy or polyethylene, applying a layer of protective tape, installing a cathodic protection system, using concrete or rock shielding, and implementing measures to prevent soil movement or impact damage.

- Q:What is the difference between steel pipes and copper-nickel pipes?

- Steel pipes and copper-nickel pipes differ in material composition and properties. Steel pipes are primarily made from iron and carbon, which provide strength and durability. They are suitable for various applications, including plumbing, construction, and industrial purposes. On the other hand, copper-nickel pipes are composed of a combination of copper and nickel, which offer excellent corrosion resistance and thermal conductivity. These pipes are often used in marine environments, desalination plants, and offshore oil and gas industries due to their ability to withstand saltwater corrosion. Overall, the main distinction lies in their composition and specific applications based on their unique properties.

- Q:How do you calculate the pipe flow velocity coefficient for steel pipes?

- The pipe flow velocity coefficient for steel pipes can be calculated using the Manning's equation. Manning's equation is used to calculate the flow velocity in open channels and pipes, and it takes into account the hydraulic radius, slope, and roughness coefficient of the pipe. To calculate the pipe flow velocity coefficient for steel pipes, follow these steps: 1. Determine the hydraulic radius (R) of the steel pipe. The hydraulic radius is calculated by dividing the cross-sectional area of the pipe (A) by the wetted perimeter (P). The formula is R = A/P. 2. Find the slope (S) of the pipe. The slope represents the change in elevation divided by the length of the pipe. It is usually given as a ratio or a percentage. 3. Determine the roughness coefficient (n) of the steel pipe. The roughness coefficient represents the internal roughness of the pipe and can be obtained from literature or pipe manufacturer specifications. It is commonly given in terms of the Manning's roughness coefficient. 4. Substitute the values of hydraulic radius (R), slope (S), and roughness coefficient (n) into the Manning's equation: V = (1/n) * R^(2/3) * S^(1/2) where V is the flow velocity. 5. Solve the equation for V to calculate the pipe flow velocity coefficient for steel pipes. It is important to note that the calculated velocity coefficient may vary based on the specific pipe dimensions, flow conditions, and other factors. Therefore, it is recommended to consult relevant engineering standards or consult with a hydraulic engineer to ensure accurate and reliable calculations for specific applications.

- Q:What are the different types of steel pipe reducers?

- There are several different types of steel pipe reducers that are commonly used in various industrial applications. These reducers are designed to connect pipes of different sizes, allowing for a smooth transition in the flow of fluids or gases. Here are some of the most common types: 1. Concentric Reducers: These reducers have a symmetrical design with a centerline that aligns with the centerline of both the larger and smaller pipes. They provide a gradual reduction in pipe size, ensuring a smooth flow of material. 2. Eccentric Reducers: Unlike concentric reducers, eccentric reducers have an offset centerline. This design is useful when there is a need to prevent the accumulation of air or gases in the piping system. The eccentric reducer helps to direct any gas or air towards a vent or drain point. 3. Welded Reducers: These reducers are made by welding two pipes of different sizes together. They are commonly used in situations where a permanent connection is required. 4. Seamless Reducers: Seamless reducers are manufactured without any welded joints. They are made from a single piece of steel, which enhances their strength and durability. Seamless reducers are often preferred in applications where leak-proof connections are critical, such as in high-pressure or high-temperature environments. 5. Threaded Reducers: These reducers have male and female threads on either end, allowing for easy installation and removal. They are commonly used in low-pressure applications and are an economical choice for systems that require frequent disassembly. 6. Flanged Reducers: Flanged reducers have flanges on both ends, which are bolted together to create a tight seal. They are often used in piping systems that require easy access for maintenance or inspection. Each type of steel pipe reducer has its own advantages and is selected based on the specific requirements of the application. It is important to consider factors such as the type of fluid or gas being transported, pressure and temperature conditions, and the need for easy installation or maintenance when choosing the appropriate reducer for a particular system.

- Q:What is the difference between the stainless steel pipe welded pipe and seamless pipe?

- Welding performance: chemical composition of seamed pipe and seamless pipe are different. The production of seamless steel components only meets the basic requirements of astm. The production of seamed tube steel containing suitable for chemical composition of welding. For example, the mixing of silicon, sulfur, manganese, oxygen, and a certain proportion of elements such as the triangle ferrite can produce a welding flux which is easy to transfer heat during welding, so as to make the whole weld be welded well. The lack of steel pipe above the chemical components, such as seamless tube, can produce all kinds of unstable factors in the process of welding, welding and welding penetration is not easy.

- Q:Are steel pipes suitable for underground gas distribution?

- Yes, steel pipes are suitable for underground gas distribution. Steel pipes are widely used in gas distribution systems due to their high strength, durability, and resistance to corrosion. They are able to withstand the pressure and stress of underground conditions, making them a reliable choice for transporting gas. Additionally, steel pipes have the advantage of being able to handle high temperatures and are resistant to fire, making them a safe option for underground gas distribution. However, it is important to ensure that the steel pipes used are properly coated and protected against corrosion to ensure their longevity and prevent any potential leaks or damage.

- Q:What are the common applications of steel pipes?

- Steel pipes have a wide range of common applications in various industries including oil and gas transportation, plumbing systems, structural support in construction, irrigation systems, and industrial processes such as water and wastewater treatment.

- Q:Are steel pipes resistant to earthquakes?

- Steel pipes are generally considered to be more resistant to earthquakes compared to other materials such as concrete or PVC pipes. This is due to the inherent properties of steel, which include its high tensile strength and flexibility. During an earthquake, steel pipes can absorb and distribute the seismic energy more effectively, allowing them to better withstand the shaking and ground movements. Additionally, steel pipes have the ability to deform without rupturing or collapsing, minimizing the risk of structural failure. However, it is important to note that the earthquake resistance of steel pipes ultimately depends on various factors such as the design, installation, and overall structural integrity of the piping system. Proper engineering and construction practices should be followed to ensure the highest level of earthquake resistance for steel pipes.

- Q:How do you prevent steel pipes from rusting?

- To prevent steel pipes from rusting, various measures can be taken. One effective method is to apply a protective coating on the surface of the pipes. This can be done using different types of coatings such as paint, epoxy, or zinc. These coatings act as a barrier between the steel and the corrosive environment, preventing moisture and oxygen from coming into direct contact with the metal and causing rust. Another approach is to use corrosion inhibitors. These substances are added to the water or fluid flowing through the pipes to create a protective film on the steel's surface. This film acts as a shield, inhibiting the corrosion process and preventing rust formation. Regular maintenance is crucial in preventing rust on steel pipes. This includes inspecting the pipes for any signs of damage or corrosion and promptly repairing or replacing any compromised areas. Additionally, keeping the pipes clean and dry by removing any accumulated dirt or moisture helps to prevent rust formation. In some cases, it may be beneficial to use stainless steel pipes instead of regular steel. Stainless steel contains chromium, which forms a passive oxide layer on the surface of the metal. This layer acts as a natural barrier against corrosion, making stainless steel pipes highly resistant to rust. Lastly, controlling the environment in which the pipes are installed can also help prevent rust. This can be achieved by maintaining proper ventilation, controlling humidity levels, and avoiding exposure to harsh chemicals or corrosive substances. By implementing these preventive measures, the lifespan and integrity of steel pipes can be significantly extended while minimizing the risk of rust formation.

After more than a decade’s construction and development, we have taken a leading position in seamless steel tube industry in China. In the year 2007, it awarded Famous-brand product Certificate. Besides, we have been named as excellent supplier of Qualified Products by our customers for several times.

1. Manufacturer Overview |

|

|---|---|

| Location | Wuxi, China |

| Year Established | 1991 |

| Annual Output Value | 300,000Tons |

| Main Markets | Europe; Southeast Asia; etc. |

| Company Certifications | API 5L;API 5CT;API Q1;ISO/TS29001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Wuxi; Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3900-4000 People |

| Language Spoken: | English; Chinese; Spanish |

| b)Factory Information | |

| Factory Size: | Above 450,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Seamless Steel Tube And Pipe For Gas Cylinder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20mt m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords