All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different bend testing requirements for seamless steel pipe?

The different bend testing requirements for seamless steel pipe typically include tests such as the guided bend test, free bend test, and wrap-around bend test. These tests assess the pipe's ability to withstand bending without fracturing or exhibiting any defects. They are important for evaluating the pipe's mechanical properties and ensuring its suitability for various applications.

What are the different methods of joining seamless steel pipe?

There are several methods of joining seamless steel pipes, including welding, threading, and flanging. Welding involves melting the edges of the pipes and fusing them together using heat. Threading involves cutting threads into the pipe ends and using a threaded fitting to join them. Flanging involves using a flange and bolts to connect two pipes together. These methods provide different options for joining seamless steel pipes, depending on the specific requirements of the application.

Can seamless steel pipes be used for steel mills?

Yes, seamless steel pipes can be used for steel mills. Seamless steel pipes are known for their high strength, durability, and ability to withstand extreme temperatures, making them suitable for various industrial applications including steel mills. They are commonly used for transporting fluids and gases, as well as for structural purposes in steel mills.

What are the common uses of seamless steel pipes in the oil and gas industry?

Seamless steel pipes are commonly used in the oil and gas industry for various purposes such as drilling, exploration, production, and transportation. They are primarily used for conveying fluids and gases over long distances, including crude oil, natural gas, and refined petroleum products. Seamless steel pipes are preferred in this industry due to their high strength, durability, and resistance to corrosion, which ensures safe and efficient operation in harsh environments. Additionally, their seamless construction allows for smoother flow of fluids, reducing friction and maximizing efficiency.

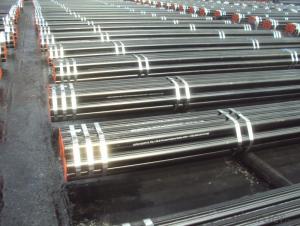

Wholesale Seamless Steel Pipe from supplier in Chile

Whether you require Seamless Steel Pipes for industrial, commercial, or infrastructure projects in Chile, we have the expertise and resources to meet your specific requirements. Our product range includes a wide variety of sizes, grades, and specifications to cater to diverse applications.

We prioritize the quality of our Seamless Steel Pipes, ensuring they meet international standards and specifications. Our products undergo rigorous quality control processes to guarantee their durability, efficiency, and reliability. You can trust in our seamless pipes to withstand high pressure, temperature, and corrosive environments, delivering optimal performance and longevity.

In addition to supplying top-quality Seamless Steel Pipes, we understand the importance of providing excellent customer service. Our dedicated team is committed to providing prompt and accurate quotations, addressing your inquiries, and assisting you throughout the procurement process. We strive to offer personalized solutions tailored to your specific project requirements.

Furthermore, we offer comprehensive technical support services to help you make informed decisions and overcome any challenges that may arise during the implementation of your projects. Our team of experts is equipped with extensive knowledge and experience in the field, enabling us to offer valuable insights and recommendations.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the backing and support of a renowned and reputable organization. This allows us to leverage our resources, networks, and expertise to provide comprehensive Seamless Steel Pipe procurement solutions in Chile. We are committed to delivering exceptional products and services that meet the highest industry standards.

Contact us today to discuss your Seamless Steel Pipe requirements in Chile and discover how we can add value to your projects.

We prioritize the quality of our Seamless Steel Pipes, ensuring they meet international standards and specifications. Our products undergo rigorous quality control processes to guarantee their durability, efficiency, and reliability. You can trust in our seamless pipes to withstand high pressure, temperature, and corrosive environments, delivering optimal performance and longevity.

In addition to supplying top-quality Seamless Steel Pipes, we understand the importance of providing excellent customer service. Our dedicated team is committed to providing prompt and accurate quotations, addressing your inquiries, and assisting you throughout the procurement process. We strive to offer personalized solutions tailored to your specific project requirements.

Furthermore, we offer comprehensive technical support services to help you make informed decisions and overcome any challenges that may arise during the implementation of your projects. Our team of experts is equipped with extensive knowledge and experience in the field, enabling us to offer valuable insights and recommendations.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the backing and support of a renowned and reputable organization. This allows us to leverage our resources, networks, and expertise to provide comprehensive Seamless Steel Pipe procurement solutions in Chile. We are committed to delivering exceptional products and services that meet the highest industry standards.

Contact us today to discuss your Seamless Steel Pipe requirements in Chile and discover how we can add value to your projects.