Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

Scaffolding Screw Jack Formwork Scaffolding China Low Price

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

Scaffolding Screw Jack Formwork Scaffolding China Low Price

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

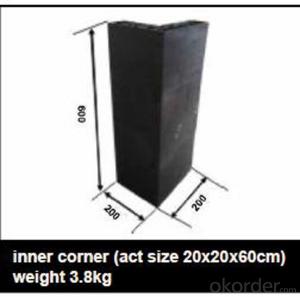

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

- Q:How does steel frame formwork handle different types of concrete surface protection methods?

- Steel frame formwork proves to be a versatile and long-lasting system capable of accommodating a variety of concrete surface protection techniques. The primary objective of safeguarding the concrete surface is to enhance both its durability and visual appeal. Numerous methods exist for ensuring this protection, including the use of surface coatings, membranes, and form liners. By utilizing steel frame formwork, a reliable and stable structure is provided for the implementation of these protective methods. Consisting of steel frames and panels specifically engineered to withstand the pressure exerted by fresh concrete during pouring and curing, this robust structure guarantees the even and effective application of concrete surface protection techniques. The utilization of steel frame formwork facilitates the easy application of surface coatings such as sealers and paints to the concrete surface. The smooth and level surface offered by the formwork system enables the straightforward application of these coatings, ensuring a uniform and consistent finish. Additionally, the steel frames provide a sturdy support system for workers, granting them access to the entirety of the surface and ensuring the thorough and accurate application of coatings. Steel frame formwork also allows for the installation of membranes such as waterproofing and vapor barriers. The formwork system's precision enables precise positioning and attachment of these membranes, guaranteeing comprehensive coverage of the concrete surface and effective protection against moisture and other external factors. The steel frames provide a robust foundation for the membranes, securing them firmly in place throughout the concrete pouring and curing processes. Moreover, steel frame formwork readily accommodates the incorporation of form liners, which are employed to create decorative patterns and textures on the concrete surface. The form liners can be affixed to the steel panels, enabling the creation of unique and visually appealing designs. The rigid structure of the steel frames ensures that the form liners remain securely in place during pouring and curing, resulting in precise and consistent patterns. To conclude, steel frame formwork is highly suitable for a diverse range of concrete surface protection methods. Its sturdy and durable structure enables the effective implementation of surface coatings, membranes, and form liners, ultimately yielding a safeguarded and aesthetically pleasing finished concrete surface.

- Q:What are the different types of edge protection systems used with steel frame formwork for bridge construction?

- There are several types of edge protection systems that are commonly used with steel frame formwork for bridge construction. These systems are designed to ensure the safety of workers and prevent accidents during construction. One type of edge protection system is the guardrail system. This system consists of metal or plastic guardrails that are installed along the edges of the formwork to provide a physical barrier between workers and the edge of the bridge. Guardrail systems are often adjustable, allowing for easy installation and removal as the construction progresses. Another type of edge protection system is the safety net system. Safety nets are typically made of strong nylon or polypropylene material and are installed below the formwork to catch falling objects or workers. These nets are designed to absorb the impact and prevent serious injuries in case of a fall. In addition to guardrail and safety net systems, some bridge construction projects may also utilize toe boards. Toe boards are horizontal boards that are installed at the base of the formwork to prevent tools, equipment, or materials from falling off the edge of the bridge. Toe boards are often made of wood or metal and are securely attached to the formwork to provide a sturdy barrier. Finally, some edge protection systems may include personal protective equipment (PPE) such as safety harnesses and lifelines. These systems are typically used in conjunction with guardrails or safety nets to provide an additional layer of protection for workers who may need to access the edge of the bridge during construction. Safety harnesses and lifelines are designed to prevent falls and allow workers to safely move about the construction site. Overall, the different types of edge protection systems used with steel frame formwork for bridge construction are designed to enhance the safety of workers and prevent accidents. The specific type of system used will depend on the requirements of the project and the regulations in place.

- Q:Main types of building templates

- 8, composite building template and its processing technology9, composite plastic building template (made of recycled plastics in accordance with the use of renewable resources)10, the improvement of the structure of the building with a combination of template 13, toughened glass combination of large formwork14, reinforced concrete component forming combination template15, steel frame plywood formwork16, the construction of light body template

- Q:Are there any specific safety considerations when using steel frame formwork?

- When using steel frame formwork, there are multiple safety considerations that must be kept in mind. To begin with, it is crucial to ensure the proper erection and securement of the steel frames in order to prevent any collapse or instability. This involves correctly aligning and leveling the frames, as well as appropriately tightening all connections and joints. The weight of the steel frames is another safety concern. They can be quite heavy, so it is important to utilize suitable lifting equipment and techniques to avoid injuries. This may entail the use of cranes, hoists, or other mechanical aids to lift and maneuver the frames. Furthermore, it is essential to take into account the potential for falls from heights when working with steel frame formwork. This necessitates the implementation of proper guardrails and edge protection systems to prevent falls, as well as the provision of appropriate personal protective equipment such as harnesses and safety helmets for workers. Fire safety is also a consideration when utilizing steel frame formwork. Steel can lose its structural integrity when exposed to high temperatures, so it is vital to have fire prevention and protection measures in place. This might involve ensuring that fire extinguishers are easily accessible, establishing evacuation plans, and providing workers with training in fire safety procedures. Lastly, it is crucial to provide adequate training and supervision to workers who are using steel frame formwork to ensure that they are aware of potential hazards and know how to work safely. Regular inspections and maintenance of the formwork should also be carried out to promptly identify and address any safety issues.

- Q:Can steel frame formwork be used in projects with limited construction resources or equipment?

- Yes, steel frame formwork can be used in projects with limited construction resources or equipment. Steel frame formwork is known for its durability and strength, making it suitable for various construction projects. Additionally, it can be easily reused multiple times, reducing the need for frequent replacements and saving costs. Its versatility allows it to be used in diverse construction scenarios, regardless of limited resources or equipment availability.

- Q:Are there any restrictions on the formwork height that can be achieved with steel frame formwork in high-rise structures?

- There are generally no specific restrictions on the formwork height that can be achieved with steel frame formwork in high-rise structures. Steel frame formwork is known for its versatility and ability to be customized to fit the specific requirements of a project. It can be easily adjusted and extended to achieve the desired formwork height for high-rise structures. However, there are a few factors that need to be considered when determining the formwork height. These include the structural stability of the formwork system, the weight-bearing capacity of the steel frame, and the safety of the workers involved in the construction process. Structural stability is crucial in high-rise structures, and the formwork system needs to be designed and engineered to withstand the loads and forces exerted by the concrete during pouring and curing. The formwork should be able to resist any deflection or deformation that may occur due to the height and weight of the concrete. The weight-bearing capacity of the steel frame formwork is also a critical factor. The formwork must be able to support the weight of the concrete, reinforcement, and any additional equipment or materials used during construction. Adequate calculations and analysis should be conducted to ensure that the steel frame can handle the anticipated loads at various heights. Furthermore, safety is paramount in high-rise construction. The formwork system should be designed and installed in compliance with relevant safety regulations and standards. Measures like guardrails, fall protection systems, and proper access should be implemented to ensure the safety of workers working at higher elevations. In summary, while there are generally no specific restrictions on the formwork height achievable with steel frame formwork in high-rise structures, factors such as structural stability, weight-bearing capacity, and safety considerations need to be carefully evaluated and addressed to ensure successful and safe construction.

- Q:What are the different types of formwork joints used with steel frame formwork?

- Steel frame formwork can be used with various types of formwork joints to ensure the stability and strength of the system during the concrete pouring process. Some commonly used joints include the butt joint, corner joint, T-joint, L-joint, Y-joint, slip joint, and key joint. The butt joint is the simplest joint, joining two panels end to end and is suitable for straight walls or columns. The corner joint connects two panels at a corner, providing stability and maintaining the desired shape. The T-joint forms a T-shape where three panels meet and is ideal for connecting intersecting walls. The L-joint, similar to the T-joint, connects two panels at a 90-degree angle, forming an L-shape, commonly used for walls or columns. The Y-joint is used for branching walls or columns, creating a Y-shape and ensuring concrete containment. The slip joint allows for movement between panels and is used in situations where thermal expansion or contraction may occur. The key joint creates a keyway in the concrete, transferring loads between adjacent pours and is commonly used in large-scale projects. Each joint serves a specific purpose and is selected based on the construction requirements. Proper installation and use of these joints are crucial for maintaining the stability and integrity of the formwork system and the resulting concrete structure.

- Q:Are there any environmental concerns associated with steel frame formwork?

- There are indeed some environmental concerns linked to steel frame formwork. Firstly, the production of steel requires a significant amount of energy and results in the emission of greenhouse gases, which contribute to climate change. The extraction and processing of raw materials for steel production also have detrimental effects on the environment, such as deforestation and the destruction of habitats. Moreover, steel frame formwork is often used only once for a specific construction project and then discarded, leading to a significant amount of waste generation and contributing to pollution in landfills. On the other hand, reusable formwork systems made from sustainable materials like bamboo or recycled plastic can help reduce waste and minimize environmental impacts. Furthermore, the transportation of steel formwork to construction sites requires fuel consumption and results in transportation emissions, which can further contribute to air pollution and carbon emissions. However, it is worth noting that steel formwork also has its advantages. It is durable, strong, and easy to assemble and disassemble, making it popular in the construction industry. Additionally, steel can be recycled, which helps reduce the environmental impact of its disposal. To address the environmental concerns associated with steel frame formwork, it is crucial to focus on improving the overall sustainability of construction practices. This can involve using more eco-friendly alternatives, implementing efficient waste management strategies, promoting recycling, and adopting sustainable transportation methods. Additionally, incorporating renewable energy sources into steel production can help reduce its carbon footprint.

- Q:Are there any specific considerations for using steel frame formwork in heritage buildings?

- Yes, there are several specific considerations for using steel frame formwork in heritage buildings. Firstly, it is important to ensure that the steel frame formwork does not cause any damage to the existing heritage structure. This can be achieved by conducting a thorough structural analysis of the building and designing the formwork accordingly. The formwork should be able to support the weight of the concrete without exerting excessive pressure on the heritage structure. Secondly, the design of the steel frame formwork should take into account any architectural or historical features of the building that need to be preserved. This may include intricate detailing, decorative elements, or specific construction techniques that are unique to the heritage building. The formwork should be flexible enough to accommodate these features and ensure their preservation. Additionally, the use of steel frame formwork should be in compliance with any heritage preservation guidelines or regulations. These guidelines may dictate specific materials, techniques, or processes that need to be followed in order to protect the integrity of the heritage structure. It is important to consult with heritage preservation experts, architects, and engineers to ensure that the steel frame formwork meets these requirements. Furthermore, steel frame formwork should be carefully installed and dismantled to minimize any potential damage to the heritage building. This may involve using specialized equipment, techniques, or protective measures to prevent any accidental impacts or vibrations. It is crucial to work closely with experienced contractors who have expertise in working with heritage structures to ensure the safety and preservation of the building. In conclusion, the use of steel frame formwork in heritage buildings requires careful consideration of the structural, architectural, and historical aspects of the building. By taking these specific considerations into account, it is possible to successfully utilize steel frame formwork while preserving the integrity and heritage value of the building.

- Q:How does steel frame formwork handle the placement of MEP (mechanical, electrical, plumbing) systems within the concrete structure?

- The versatility and efficiency of steel frame formwork make it an excellent choice for accommodating MEP systems in concrete structures. The sturdy steel frames provide reliable support, allowing for seamless integration of MEP components. One of the main advantages of steel frame formwork is its adaptability. The frames can be easily customized to meet the specific requirements of MEP systems, including creating openings for pipes, conduits, and ducts. This flexibility ensures that MEP systems can be incorporated efficiently without compromising the integrity of the concrete structure. In addition, steel frame formwork offers exceptional load-bearing capabilities, which is crucial considering the weight and potential vibrations associated with MEP systems. The strong and durable steel frames can withstand the weight and movement of MEP components, providing a stable platform for their installation. Furthermore, steel frame formwork allows for precise placement of MEP systems. The frames can be easily aligned and leveled, ensuring accurate installation. This is especially important in complex MEP installations to avoid clashes between different systems. Moreover, steel frame formwork simplifies the installation and maintenance of MEP systems. The frames provide easy access to the components, facilitating convenient installation, inspection, and maintenance. This accessibility allows for efficient repairs and modifications, reducing downtime and minimizing disruptions to the concrete structure. In conclusion, steel frame formwork is an efficient and effective system for integrating MEP systems into concrete structures. Its adaptability, load-bearing capabilities, precision, and accessibility make it an ideal choice for seamless integration of MEP components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Scaffolding Metal Deck Formwork Scaffolding Wire For Wholesales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords