Table Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

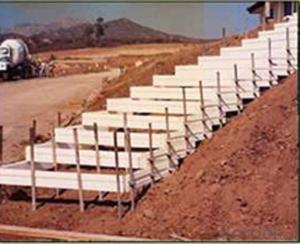

Tabel Formwork:

Table formwork is the most typical application for slab, with timber beam, the slab formwork is

light weight, fast and economic in the construction.

Characteristics:

◆ Simple structure, easy assembly.

◆ Flexible structure, be adapted to different support system.

◆ High construction efficiency with special system tools.

1. Lifting fork for lifting the table formwork to upper floor.

2. Trolley for moving the table formwork on floor.

◆ Flexible application with stand alone props.

◆ Safer condition with handrails.

- Q:What safety measures need to be taken when using steel frame formwork?

- To ensure the well-being of workers and the overall success of the construction project, it is important to take several safety measures when using steel frame formwork. These measures include: 1. Providing adequate training: Workers should receive proper training on how to handle and assemble steel frame formwork. This includes understanding the correct procedures for setting up, dismantling, and moving the formwork. 2. Conducting regular inspections and maintenance: It is essential to regularly inspect the steel frame formwork to identify any potential hazards or defects. Any damaged or faulty parts should be repaired or replaced immediately to prevent accidents. 3. Ensuring secure anchorage: It is crucial to securely anchor the steel frame formwork to the supporting structure to prevent unexpected movements or collapse, reducing the risk of injuries. 4. Providing fall protection: Workers should be given appropriate fall protection measures when working at heights on the steel frame formwork. This may involve using safety harnesses, guardrails, or safety nets. 5. Promoting proper lifting techniques: Workers should use proper lifting techniques when moving or handling steel frame formwork to avoid strains or injuries. Mechanical lifting equipment, such as cranes or forklifts, should be utilized to minimize physical strain. 6. Encouraging clear communication: Effective communication between workers is important to ensure everyone understands their roles and responsibilities when working with steel frame formwork. Clear instructions and signage should be provided to prevent misunderstandings or confusion. 7. Providing adequate lighting and ventilation: Proper lighting and ventilation should be available in the area where steel frame formwork is being used. This will improve visibility and reduce the risk of accidents caused by poor lighting or inadequate air circulation. 8. Supplying personal protective equipment (PPE): Workers should be given the necessary PPE, such as hard hats, safety goggles, gloves, and steel toe boots, to protect them from potential hazards. By implementing these safety measures, construction companies can minimize the risks associated with using steel frame formwork, creating a safer working environment for their employees and ensuring a successful construction project.

- Q:How does steel frame formwork affect the overall energy efficiency of a structure?

- The overall energy efficiency of a structure can be greatly influenced by steel frame formwork. Firstly, the construction process benefits from a robust and long-lasting support system offered by steel frame formwork, allowing for precise and accurate concrete placement. This ensures high-quality standards in construction, reducing the need for future repairs or modifications that would consume additional energy. Moreover, the insulation and thermal performance of the structure can be improved by implementing steel frame formwork. By incorporating insulation materials within the formwork, the building's walls and floors can be effectively insulated, minimizing heat transfer and enhancing energy efficiency. This is especially vital in regions with extreme temperatures, as it reduces reliance on heating or cooling systems, resulting in lower energy consumption and associated costs. Additionally, steel frame formwork allows for the seamless integration of renewable energy systems, such as solar panels or wind turbines, during the construction phase. These energy sources can be effortlessly incorporated into the formwork, augmenting the structure's overall energy efficiency by generating renewable energy on-site. Lastly, opting for steel frame formwork makes for a sustainable and environmentally friendly choice. Steel is a highly recyclable material, reducing the need for new resources and minimizing waste in the construction process. By choosing steel frame formwork, the carbon footprint of the construction project can be significantly reduced, contributing to a more sustainable and energy-efficient structure. In conclusion, steel frame formwork positively impacts the overall energy efficiency of a structure through its strong support system, improved insulation and thermal performance, integration of renewable energy systems, and promotion of sustainability.

- Q:What are the different types of accessories and attachments available for steel frame formwork?

- Steel frame formwork offers a range of accessories and attachments that serve to improve the system's performance and streamline the construction process. An adjustable prop stands out as one of the most commonly used accessories. It lends support to the formwork system, ensuring its stability. With the ability to easily adjust to varying heights, these props offer flexibility in construction projects. Formwork clamps are another crucial accessory. They securely fasten the formwork panels together, preventing any movement or displacement during concrete pouring. Formwork brackets are commonly employed accessories as well. They attach to the steel frame formwork, providing additional support to the formwork panels and beams. This results in improved stability and strength for the system. Formwork connectors are used to connect the formwork panels together, while formwork ties secure the formwork system to the structure being constructed. In addition to these accessories, various attachments are available for steel frame formwork. For instance, the formwork corner allows for the creation of sharp corners and angles in the formwork system. This attachment ensures that the formwork can be adjusted to meet the specific design requirements of a construction project. Another attachment, the formwork bracket arm, extends the reach of the formwork brackets, facilitating greater flexibility in formwork placement. Overall, the array of accessories and attachments for steel frame formwork aims to enhance stability, flexibility, and functionality. By incorporating these accessories and attachments, the construction process becomes more efficient and effective, leading to a higher quality finished product.

- Q:How does steel frame formwork handle the placement of fire-rated barriers and partitions within the concrete structure?

- Steel frame formwork provides a robust and efficient solution for the placement of fire-rated barriers and partitions within a concrete structure. With its strong and durable nature, steel frame formwork ensures the accurate positioning and alignment of these fire-rated elements. The rigid framework allows for precise installation, ensuring that the barriers and partitions are securely embedded within the concrete structure, providing reliable fire protection. Additionally, steel frame formwork allows for easy adjustment and modification when necessary, making it a versatile choice for incorporating fire-rated barriers and partitions into the concrete structure.

- Q:What safety precautions should be taken when using steel frame formwork?

- When using steel frame formwork, several safety precautions should be taken to ensure the well-being of workers and the successful completion of the construction project. Here are some important safety precautions to consider: 1. Training: All workers involved in the use of steel frame formwork should receive proper training on its assembly, disassembly, and handling. This training should cover relevant safety guidelines and procedures. 2. Inspection: Before using steel frame formwork, it is crucial to inspect it thoroughly. Check for any damaged or worn-out parts, sharp edges, or loose connections. Any defects should be repaired or replaced immediately. 3. Proper storage: When not in use, steel frame formwork should be stored in a designated area, away from heavy equipment or potential hazards. It should be stacked securely, ensuring that it cannot collapse or fall. 4. Personal Protective Equipment (PPE): Workers should always wear appropriate PPE, including hard hats, safety goggles, gloves, and safety boots, to protect themselves from potential hazards such as falling objects or sharp edges. 5. Fall protection: Steel frame formwork is often used at heights, so fall protection measures must be in place. This may include the use of guardrails, safety nets, or personal fall arrest systems to prevent falls and minimize the risk of injuries. 6. Secure installation: Steel frame formwork should be properly secured to prevent any movement or collapse during usage. This involves ensuring that all connections are tightened and all support elements are correctly positioned. 7. Regular maintenance: Regular maintenance and inspections should be conducted on the steel frame formwork to identify any defects, such as rust or structural damage, and address them promptly. This will help maintain its integrity and ensure safe usage. 8. Communication and coordination: Effective communication and coordination among all workers involved in the use of steel frame formwork are essential. This includes clear instructions, proper signaling, and adherence to safe work practices. By following these safety precautions, the risk of accidents or injuries when using steel frame formwork can be significantly reduced. It is crucial to prioritize safety at all times and regularly review and update safety procedures to ensure a safe working environment.

- Q:What is the typical lifespan of steel frame formwork?

- The typical lifespan of steel frame formwork can vary depending on various factors such as the quality of the steel, the type of construction projects it is used for, and the maintenance and care it receives. However, with proper care and maintenance, steel frame formwork can have a lifespan of 10 to 15 years or even more. Steel frame formwork is known for its durability and strength, making it suitable for multiple uses in construction projects. With regular cleaning, rust prevention, and proper storage, the steel frames can withstand the wear and tear of repetitive use and exposure to weather conditions. However, it is important to note that the lifespan of steel frame formwork can be significantly reduced if it is subjected to harsh conditions, such as extreme temperatures or corrosive environments. In such cases, the frames may require more frequent maintenance and repairs to prolong their lifespan. Ultimately, the longevity of steel frame formwork is highly dependent on the usage and maintenance practices. By following recommended maintenance procedures and ensuring timely repairs, the lifespan of steel frame formwork can be maximized, providing cost-effective and reliable solutions for construction projects.

- Q:What are the different types of formwork bracing used with steel frame formwork?

- There are several different types of formwork bracing that can be used with steel frame formwork. These bracing systems are designed to provide support and stability to the formwork during the concrete pouring process. 1. Adjustable Steel Props: Adjustable steel props are commonly used as vertical bracing elements. They consist of a steel tube with a threaded end and a base plate. The props can be adjusted to different heights and are secured in place using locking pins. 2. Horizontal Steel Bracing: Horizontal steel bracing is used to provide lateral stability to the formwork. This type of bracing consists of steel tubes that are connected to the vertical props and secured using clamps or couplers. The bracing is typically installed at regular intervals along the length of the formwork. 3. Diagonal Bracing: Diagonal bracing is used to provide diagonal support to the formwork. This type of bracing is made up of steel tubes that are connected to the vertical props and secured using clamps or couplers. Diagonal bracing is typically installed at different angles to provide maximum stability. 4. Tie Rods: Tie rods are used to provide additional strength and stability to the formwork. They consist of steel rods that are threaded at both ends and are used to connect the formwork panels together. The tie rods are tightened using nuts and washers to hold the formwork in place. 5. Cross Bracing: Cross bracing is used to provide additional lateral stability to the formwork. This type of bracing consists of steel tubes that are connected diagonally between the vertical props. Cross bracing is typically installed at regular intervals to prevent any shifting or movement of the formwork. Overall, the different types of formwork bracing used with steel frame formwork are designed to provide support, stability, and strength to the formwork system during the concrete pouring process. These bracing systems ensure that the formwork remains in place and can withstand the pressure exerted by the concrete.

- Q:Can steel frame formwork be used for bridge and infrastructure construction?

- Bridge and infrastructure construction can indeed utilize steel frame formwork. This type of formwork is versatile and long-lasting, providing effective support for concrete during the construction process. Its ability to withstand heavy loads and maintain stability makes it particularly suitable for large-scale projects like bridges and infrastructure. There are numerous advantages to using steel frame formwork in bridge and infrastructure construction. Firstly, it enables quick and precise assembly, guaranteeing a high level of accuracy and quality in concrete placement. This precision is crucial for ensuring the structural integrity of bridges, where exact alignment is essential. Secondly, steel frame formwork is highly reusable, offering both cost-effective and environmentally-friendly benefits. With proper maintenance and care, the same formwork can be used for multiple projects, reducing the need for new materials and minimizing waste. Furthermore, steel frame formwork provides exceptional strength and stability, making it ideal for supporting large spans and heavy loads, both of which are commonly encountered in bridge and infrastructure construction. The steel frames are capable of withstanding the pressure exerted by wet concrete, ensuring the overall stability and durability of the structure. Additionally, steel formwork systems offer design flexibility and can be customized to meet the specific requirements of each project. This allows engineers and contractors to adapt the formwork to accommodate the unique shape and size of the bridge or infrastructure being constructed. In conclusion, steel frame formwork is a dependable and efficient solution for bridge and infrastructure construction. Its strength, durability, reusability, and flexibility make it an ideal choice for these types of projects, guaranteeing the successful completion of complex structures with high-quality concrete placement.

- Q:How does steel frame formwork contribute to better concrete curing?

- Steel frame formwork is a construction technique that utilizes steel frames to create molds into which concrete is poured. This method of formwork offers several advantages that contribute to better concrete curing. Firstly, steel frame formwork provides a high level of precision and stability during the pouring of concrete. The steel frames are designed to be rigid and have accurate dimensions, ensuring that the formwork maintains its shape and does not deform during the curing process. This precision enables the concrete to cure evenly, reducing the risk of cracking or uneven surfaces. Additionally, the use of steel frames allows for easy customization and flexibility in formwork design. The frames can be easily adjusted and modified to accommodate various shapes and sizes of concrete structures. This adaptability ensures that the formwork fits the specific requirements of the project, resulting in better concrete curing and a higher quality finished product. Moreover, steel frame formwork provides excellent support and reinforcement for the concrete during the curing process. The steel frames act as a strong framework, preventing the concrete from sagging or bulging while it hardens. This support ensures that the concrete maintains its desired shape and form, resulting in a more durable and structurally sound final product. Furthermore, steel frame formwork allows for efficient and convenient removal once the concrete has cured. The frames can be easily disassembled and reused for future projects, reducing waste and saving costs. This efficient removal process minimizes the disruption to the curing concrete and ensures that the curing process is not disturbed, leading to better overall curing results. In conclusion, steel frame formwork contributes to better concrete curing through its precision, stability, support, and flexibility. By providing a high level of accuracy and strength, this construction technique ensures that the concrete cures evenly, resulting in a higher quality finished product. Additionally, the adaptability and efficient removal process offered by steel frame formwork further enhance the overall curing process and contribute to better concrete outcomes.

- Q:What are the different types of joints used in steel frame formwork?

- Steel frame formwork utilizes various types of joints, each serving a distinct purpose in the construction process. 1. The most commonly employed joint in steel frame formwork is the butt joint. This joint involves connecting two steel members end to end, resulting in a seamless and flush connection. Typically, butt joints are utilized in straight sections of the formwork where angular changes are not required. 2. A lap joint is employed when two steel members need to be connected side by side. In this joint, one member overlaps the other and is subsequently welded or bolted together. Lap joints are often used in corners or areas with high load-bearing requirements to enhance strength and stability. 3. Corner joints are specifically used to connect steel members at corners or angles. These joints are designed to ensure a robust and stable connection, enabling the formwork to retain its shape and withstand the forces exerted during the concrete pouring process. 4. T-joints are implemented to connect three steel members in a T-shape configuration. These joints are commonly used to provide additional support or reinforcement at specific points within the formwork system. 5. Splice joints are employed to connect two steel members end to end, similar to butt joints. However, splice joints are typically used in longer sections of the formwork where a seamless connection is not necessary. These joints are often utilized in situations where ease of assembly and disassembly is of utmost importance. Ultimately, the selection of a joint for steel frame formwork depends on the specific requirements of the construction project. Each type of joint offers unique advantages in terms of strength, stability, and ease of assembly, allowing the formwork system to be tailored to meet the project's needs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Table Formwork System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords