Q13(QB)136 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

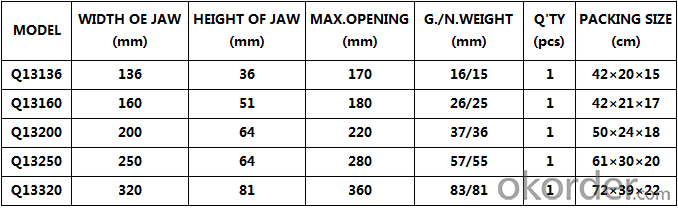

Q13(QB) SeriesMachine Vice

Performance and character:

1. It adopts the high-quality cast irons.

2. Both parallelismand verticality about the two jaws are 0.025mm/100mm.

3. It is widelyused for the milling machine and the drilling machine to process some surface,slots and holes.

- Q:Is there a god who is good at drawing mechanical drawings?

- The bench vice is the necessary tool for the fitter, and is also the source of the fitter's name, because most of the work of the fitter is vise

- Q:What is the commonly used workpiece in milling machine

- Parallel-jaw vice parallel-jaw vice has great versatility and economy, is suitable for smaller square workpiece clamping:) nc milling machine commonly used parallel-jaw vice, often using mechanical screw, pneumatic or hydraulic clamping way.. The tongs of the pincers can be made in various forms and different forms of tongs, which can be used to enlarge the use of the machine. The various forms of the pincers' jaws. Using flat pliers clamping workpiece, according to the first of the artifacts the high precision of cutting height within the flat pliers mat parallel mat iron, in order to make sure. Won't produce in the process of cutting workpiece moving; The second is to find the right of the pincers to ensure that the tongs of the pincers are parallel or perpendicular to the direction of the main shaft cutter. Parallel-jaw vice jaw's alignment method, the indicator with the magnetic table fixed on the spindle, indicator contact contact jaw, along the direction parallel to the jaw moving axis, according to the using readings tongbang tapping parallel-jaw vice adjustment, to ensure that the jaw and parallel or vertical axis direction.

- Q:The large aluminum plate will not deform 250 * 240 * 16

- After testing, you can stabilize the appropriate holding force ~ if you need detailed parameter data, you can trust me, or leave a

- Q:What do you mean by rotating mechanical vice

- It is a kind of tool that can rotate mechanical devices.

- Q:How do milling machine tongs correct

- The left and right side of the bed allows the probe to be moved to the other end of the machine with the tongs, and the measuring reading is different. If different, the machine with soft head hammer and light hammer side of the machine vice side, correct and correct, the machine will be clamped tightly. In general, because of the precision of the vice structure of the machine, it is not necessary to check the parallel degree of the bottom surface of the tongs of the xoxen milling machine

- Q:Do you use a hammer to hit the handle with a clamp?

- Usually not, the screw in the vice clamp should be clamped up so that when you don't use a lot of force on it, it will slip

- Q:The structure of a vice

- The work surface of the tongs is intersected, which makes it difficult to slip when the workpiece is clamped. The tongs are hardened by heat treatment and have good abrasion resistance. Fixed clamp body in a seat, and can rotate axis rotation, when transferred to the requirements of the direction, turn the clamping handle make the clamping screw tightening, can be in the clamping plate under the action of the fixed clamp body is solid and tight. There are three bolt holes in the seat to be fixed with the clamp.

- Q:Who has a parts drawing and assembly diagram for a vice?

- I hope I can help you. Learning ug is a problem, it can be sent to the problem supermarket of abcug BBS, there are more people to answer with you.

- Q:How to draw a vice assembly drawing

- Draw a secondary structure. Check the proofs and revise the supplement.

- Q:How to find a positive two vice

- Then adjust the level of water level (both of which are consistent with the working table) - the magnetic watch seats are drawn on the main shaft

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q13(QB)136 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches