prefab steel warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

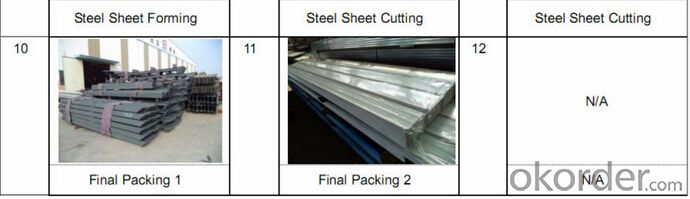

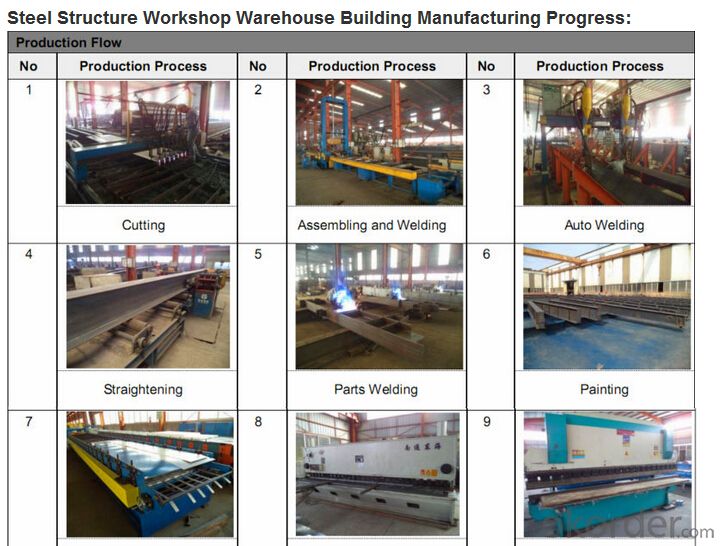

steel structure warehouse/sheds/factory Specifications

Prefabricated House.

Repeat use and long life.

Anti-rust.low cost

| Material | C Purlin, H Beam, Sandwich panel, Hot Galvanised Steel, etc. |

| Features | 1. Firm and Artistic |

| 2. Durable for 30 years at least. | |

| 3. Reusale, and Easy to intall and dismantle: usually, one worker could install 20-30 square meters per day, six workers could work out 3K*10K houses in two days. | |

4. Extensive Applications: Warehouse, Plant, Exhibition Hall, Terminal Building, Stadium, Theater, Special-shaped Buildings. | |

| 5. Hot Galvanised… | |

| 6.Flexible composition: Doors and Windows could be installed at any positions,Separate Walls could be built at any transverse axis. Stairs could be outside Steel buildings. |

- Q:What are the design considerations for steel healthcare campuses?

- Some design considerations for steel healthcare campuses include structural integrity, flexibility for future expansion, infection control measures, efficient space utilization, and accessibility for patients with disabilities. Additionally, incorporating natural light, creating a soothing and healing environment, and implementing sustainable design features are also important considerations.

- Q:What are the considerations for steel structure design in earthquake-prone areas?

- When designing steel structures in earthquake-prone areas, it is important to take into account several key considerations to ensure the safety and stability of the structure during seismic events. The first consideration is to adhere to the specific seismic design codes and regulations for the region. These codes provide guidelines for designing, constructing, and maintaining structures in earthquake-prone areas. A thorough structural analysis must be performed to determine the expected seismic forces and their effects on the steel structure. This analysis involves assessing the building's response to ground motion, evaluating the strength and deformation capacity of the steel elements, and considering the interaction between various components. Steel structures in earthquake-prone areas should be designed with high ductility and redundancy. This means that the structure should be able to deform without losing its load-carrying capacity, and it should be able to redistribute loads and resist failure even if certain elements are damaged. Moment-resisting frames are commonly used in seismic design to provide resistance against lateral forces. These frames consist of beams and columns connected by rigid or semi-rigid connections, allowing them to effectively transfer forces and moments. Base isolation techniques can be used to separate the structure from the ground using flexible bearings or isolators. This helps to reduce the transmission of seismic energy to the building. Damping devices such as viscoelastic dampers or tuned mass dampers can also be incorporated to dissipate energy during earthquakes. Existing steel structures in earthquake-prone areas may need to be strengthened to meet the seismic design requirements. Techniques such as adding bracing systems, steel jackets, or external post-tensioning can be employed to improve the structure's resistance to earthquakes. Considering the interaction between the steel structure and the underlying soil is crucial. The characteristics of the soil, such as its stiffness and damping properties, can significantly affect the seismic response of the structure. Soil-structure interaction analysis should be conducted to ensure the design accounts for these effects. Regular quality control checks and inspections during construction are essential to ensure that the steel structure is being built according to the design specifications. Special attention should be given to welding, connections, and material quality to ensure the integrity of the structure. By considering these aspects, engineers can design steel structures that can withstand seismic forces and minimize damage, ensuring the safety of occupants and preserving the structural integrity of the building in earthquake-prone areas.

- Q:Are there any restrictions or regulations for building steel structures?

- Yes, there are restrictions and regulations for building steel structures. These regulations vary by country and region but typically include guidelines for structural design, material specifications, construction techniques, and safety measures. Building codes and standards, such as those set by organizations like the American Institute of Steel Construction (AISC) or the International Building Code (IBC), provide comprehensive guidelines to ensure the structural integrity and safety of steel buildings. Compliance with these regulations is crucial to ensure the durability, stability, and safety of steel structures.

- Q:What are the types of steel structures?

- Steel structure is a structure made of steel material, and is one of the main types of building structures. The structure is mainly composed of steel beams and steel plates, such as steel beams, steel columns, steel trusses and so on. Each component or component is usually connected with welds, bolts or rivets. Because of its light weight and simple construction, it is widely used in large factories, stadiums, super high-rise and other fields.

- Q:How do steel structures meet building code requirements?

- Steel structures meet building code requirements by being designed and constructed in accordance with industry standards and regulations. This includes following specific guidelines for structural integrity, fire safety, seismic resistance, wind load capacity, and other relevant factors. Steel's high strength-to-weight ratio, durability, and versatility make it a preferred material for meeting these requirements, as it can withstand various loads and environmental conditions. Additionally, steel structures undergo thorough inspections and testing during the construction process to ensure compliance with building codes and ensure the safety of occupants.

- Q:What are the factors to consider when designing steel structures for retail and commercial spaces?

- When designing steel structures for retail and commercial spaces, several factors need to be considered. These include the load requirements, such as the weight of the building, equipment, and inventory. The design must also account for the specific needs of the retail or commercial space, such as the layout, flexibility for future expansions or alterations, and the aesthetic appeal. Additionally, factors like the location's climate, seismic activity, and local building codes must be considered to ensure the structure's safety and durability.

- Q:How are steel structures designed for exhibition centers?

- Steel structures for exhibition centers are designed with careful consideration of various factors to ensure their functionality, safety, and aesthetic appeal. Firstly, the design process begins with assessing the specific requirements and constraints of the exhibition center. This includes determining the size and shape of the space, as well as the load-bearing capacity needed to support the weight of the exhibits, equipment, and visitors. Steel is often chosen for its high strength-to-weight ratio, making it ideal for constructing large-scale structures. Next, the design team considers the architectural concept and style of the exhibition center. The steel structure must complement the overall design and create a visually appealing space. This involves selecting the appropriate steel profiles and connections to achieve the desired aesthetic while maintaining structural integrity. Structural engineers play a crucial role in the design process. They analyze the loads, such as wind, snow, and seismic forces, that the steel structure will be subjected to, ensuring it can withstand these forces without compromising safety. Computer-aided design software is commonly used to simulate and analyze the behavior of the structure under various conditions. In addition to strength and aesthetics, functionality is a key consideration. Exhibition centers often require large open spaces with minimal obstructions to accommodate exhibits and allow for flexible use of the space. Steel structures can provide wide spans and open floor plans, allowing for the creation of expansive exhibition halls and versatile layouts. Another important aspect is the integration of various building systems within the steel structure. This includes HVAC (heating, ventilation, and air conditioning), lighting, electrical, and plumbing systems. The steel framework must be designed to accommodate these systems, ensuring efficient functionality and ease of maintenance. Lastly, sustainability and energy efficiency are increasingly important considerations in the design of exhibition centers. Steel is a highly sustainable material as it is recyclable and can be fabricated off-site, reducing waste and construction time. Additionally, the design may incorporate energy-efficient features such as natural lighting, insulation, and renewable energy sources to reduce the environmental impact of the exhibition center. In conclusion, steel structures for exhibition centers are carefully designed to meet the specific requirements of the space, while considering factors such as aesthetics, functionality, safety, and sustainability. The design process involves collaboration between architects, structural engineers, and other professionals to create an innovative and visually striking space that can accommodate a wide range of exhibits and events.

- Q:What are the key considerations in the design of steel structures for educational facilities?

- The key considerations in the design of steel structures for educational facilities include factors such as safety, functionality, flexibility, durability, and sustainability. Safety is paramount, with the design needing to meet all relevant building codes and regulations to ensure the protection of students, staff, and visitors. Functionality is crucial, as the design should accommodate various educational activities, from classrooms to laboratories, libraries, and recreational spaces. Flexibility is also important to allow for future expansion or changes in the educational programs. Durability is a key consideration to ensure the longevity of the structure and minimize maintenance costs. Lastly, sustainability plays a significant role in the design, with a focus on energy efficiency, use of sustainable materials, and incorporation of green technologies to minimize the environmental impact of the facility.

- Q:How are steel structures used in educational laboratories and research facilities?

- Educational laboratories and research facilities extensively utilize steel structures due to the multitude of advantages they offer. To begin with, steel possesses remarkable strength and durability, rendering it ideal for the construction of large and intricate edifices. In such settings, steel structures are employed to fashion expansive and adaptable spaces capable of accommodating diverse experiments and equipment. Furthermore, steel structures exhibit superb resistance to fire, earthquakes, and other severe weather conditions, thereby ensuring the safety of students, researchers, and valuable equipment. This is of particular significance in locations prone to natural disasters or where hazardous experiments are conducted. Moreover, steel structures provide exceptional design and customization flexibility. They can be effortlessly altered and expanded to meet the evolving needs and requirements of the laboratory or research facility. This adaptability permits the integration of specialized rooms, such as cleanrooms, containment areas, or vibration-free spaces, which are indispensable for conducting specific experiments and research. Additionally, steel structures boast a lengthier lifespan in comparison to traditional construction materials. Their minimal maintenance demands and resistance to corrosion and decay make them a cost-effective choice in the long term. This frees up funds for investment in cutting-edge equipment and technology, thereby enhancing the educational and research capabilities of the facility. Lastly, steel structures deliver excellent acoustic and thermal insulation, fostering a conducive environment for focused research and learning. These structures can be designed to minimize noise and vibrations, which is crucial in sensitive experiments or when multiple experiments are being conducted concurrently. In conclusion, steel structures play an indispensable role in educational laboratories and research facilities, providing strength, durability, safety, versatility, and cost-effectiveness. Their utilization ensures the creation of well-equipped, flexible, and efficient spaces that promote innovation, scientific advancements, and educational excellence.

- Q:What are the safety considerations when working with steel structures?

- When working with steel structures, several safety considerations should be taken into account. Firstly, it is important to ensure proper training and knowledge of steelwork as it involves heavy materials, complex machinery, and potentially hazardous equipment. Secondly, personal protective equipment (PPE) such as helmets, gloves, and steel-toed boots should be worn to protect against potential injuries. Additionally, proper lifting techniques and equipment should be used to prevent strains and accidents during the handling of heavy steel components. Regular inspections of the structure for any signs of damage or deterioration are crucial to maintain its integrity and prevent accidents. Lastly, following all relevant safety regulations and guidelines, and having a comprehensive emergency response plan in place, are essential to minimize risks and ensure the well-being of workers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

prefab steel warehouse building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords