Plastic White Masterbatch Color & Additive Master Batch for Film PPR Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

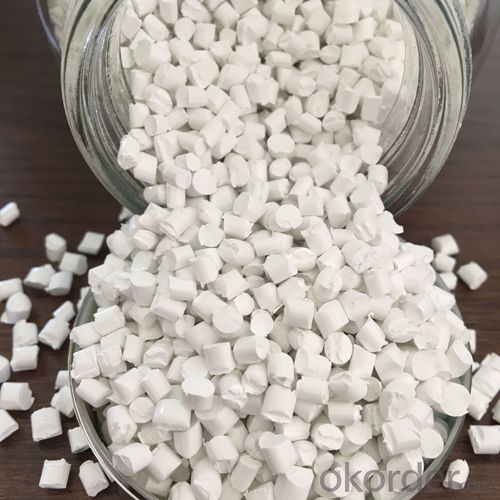

White masterbatch is made of imported Tio2 and virgin pe resin and additives production

Effect:High covering,spread evenly,strong tinting strength

Additive amount:2%-10% amount is recommened.Or adjust the dosage as per your products performance

Application:blowing film,casting film,packing film,PP-R Pipe,ect

Packaging:Paper-plastic compound bags,or PE bags,25kg net weight/bag.

Advantage of White Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of White Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

Product Pictures of White Masterbatch

- Q:How to use all kinds of plastic materials?

- GPPS modified polystyrene 204The transparency of 88-92%, refractive index 1.59-1.60, suitable for light products, dyeing is strong, non-toxic and tasteless, no fungus growth, high impact strength, resistance to acid and alkali resistant performance is good, not on the basis of solvent, excellent electrical properties, easy molding, moisture less than 0.02% can maintain the strength and size of high humidity, but the brittleness.Suitable plastic products: decorations, lighting signs, lampshades, stationery, transparent toys, daily necessities, instrument lenses, freezers and thermal insulation in the refrigerator (after foaming).

- Q:What kinds of plastic properties can be divided into thermal properties?

- A. thermoplastic(a) polyvinyl chloride (PVC)Is the most widely used plastic varieties. Polyvinyl chloride resin is made from poly (vinyl chloride) monomer. According to the amount of plasticizer, it is divided into hard PVC and soft PVC. The former adds 30~70 phr of plasticizer <5 in 100 heavy resins, and the latter adds plasticizers.Physical properties: the relative density of hard PVC is 1.35 to 1.60, which is 1 / 5 of carbon steel; the relative density of soft PVC is 1.2 ~ 1.4.The water absorption rate of hard PVC is very low. The water absorption rate in long-term immersion in water is <0.5%; the soaking water is 24h, and the water absorption is 0.05%. The permeability of PVC is very low.The glass state temperature of PVC is 80~85 DEG C, the viscosity is 180 DEG C, the decomposition temperature is 240~260 DEG C (including stabilizer), and the brittleness temperature is -50 ~ -60 DEG C.The recommended temperature range of hard PVC is, in principle, maintained in terms of brittleness and glass temperature. If it is used above 50 degrees, necessary measures should be taken.The pure PVC, without stabilizers, begins to decompose at 150 C, releases hydrogen chloride, and further accelerates its decomposition. It decomposes faster than 180 DEG C. The polyvinyl chloride with the stabilizer decomposes the temperature to 240~260 degrees centigrade, but breaks down hydrogen chloride if used for 220 years. The material changes from dark grey to yellow brown, or even black. Therefore, in welding, we should try to avoid this phenomenon, the linear expansion coefficient of hard polyvinyl chloride is (5~6) X10-5 / DEG, 5-6 times larger than carbon steel. Therefore, when installing polyvinyl chloride pipes, expansion joints or bracing shall be installed to prevent deformation. When polyvinyl chloride is used as lining or bonding with other materials, the peeling phenomenon may be considered when heated.

- Q:What material is best for plastic gears?

- The most commonly used is the POM. It can be made of carbon fiber reinforced, more stable size, of course, can also use high-end engineering plastics, such as: PEEK, SP-1, Teflon, LR, and so on. For different occasions, different characteristics of the use of choice

- Q:What kind of material is the raw material of plastic pipes?

- Plastic pipe raw material is plastic particles, according to the pipeline production processing performance requirements, with the different requirements of finished products, there are different manufacturers grades, grades and performance differences.

- Q:Chemical, plastic raw materials, plastic raw materials how sub grade?

- Plastic bucket is usually added to the resin, in the production of lubricants, plasticizers, dispersant, pigment, polyethylene wax, and these materials good variety, price range, and some high melting point, good whiteness, production out of the finished product is good texture, high brightness, good conscience manufacturers add some heat thermoplastic elastomer, feel very well; and a point of the raw materials, the relative performance is low, the production of plastic barrels must be of poor quality.

- Q:What is the difference between PP raw material and modified PP?

- PP raw materials refer to resinsConcept: the word "plastic" in the word "plastic material" is intended as a material or plastic material that can be arbitrarily shaped into various shapes. In the dictionary is defined as "synthetic or natural polymers as the main component, under certain conditions can plasticization and molding can keep shape, the end product of materials.

- Q:What are the common raw materials used in plastic bottles? What are the main features?

- PC bottles are transparent, shock resistant and high temperature resistant. They are expensive. 5 gallon pure water bottles are used at most. They can be sterilized by high temperature steam.The key depends on what you want to install, there is no corrosive, appearance requirements, and so on, decided to use what materials.

- Q:How do plastic materials come from?

- Plastic materials: is made of macromolecule resin (polymer) as the main ingredients penetrate various auxiliary materials or additives, in particular temperature, has the plasticity and fluidity under pressure, can be molded into shape and maintain the same shape of material under certain conditions.

- Q:What are the raw materials of plastics made of?

- Some plastics are pure resins, such as polyethylene, polystyrene and so on. They are called single component plastics. Some plastics, in addition to synthetic resins, also contain other auxiliary materials, such as plasticizers, stabilizers, colorants, various fillers, etc., known as "multi component plastic.".

- Q:What is the material of plastic flat screen?

- It is made of hot spraying and cold fixing. It has the characteristics of wear resistance, corrosion resistance, toughness and so on. It can be used as a substitute for wire. The utility model has the advantages of corrosion resistance, light weight, long service life, no poison, no smell and good transparency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic White Masterbatch Color & Additive Master Batch for Film PPR Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords