Portable Floss Roll Clean Environmentally Friendly Floss Roll For House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Portable Floss roll clean environmentally friendly floss roll for house

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Brand OEM/Ok Floss

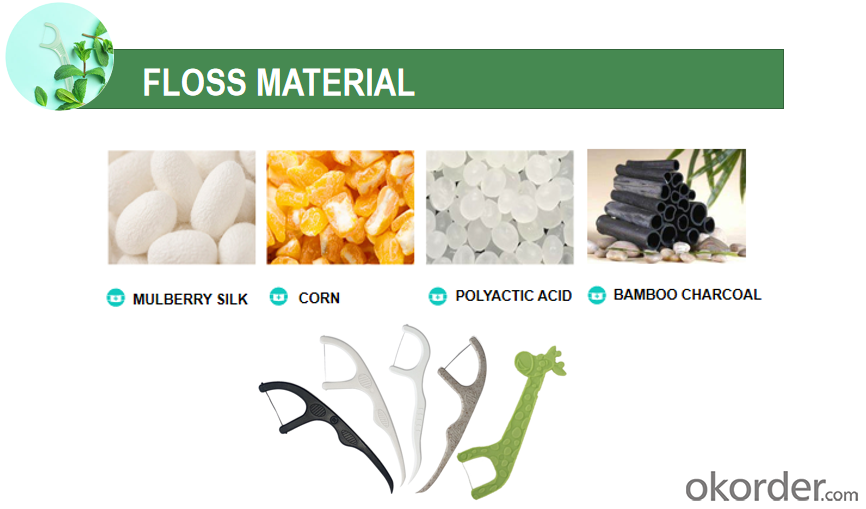

Floss materialCharcoal ,UHMWPE ,nylon

Floss length7.4*2.2cm/25-30M/OEM

WaxImport germany wax/american wax/bee wax/candelilla wax/customized wax

FlavorMint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss original color

Floss original colorIndividual bulk PP bag/individual paper box/as customized

ApplicationsFamily,Hotel,Travel,Supermarket

DeliveryBy sea,By air,By express.

Lead time20-30days

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots where your

toothbrush can’t reach, generally between your teeth and under the gumline.

Various flavors to choose:Mulberry Silk,Corn, Polyactic Acid, Bamboo Chacoal, and any flavor you want.

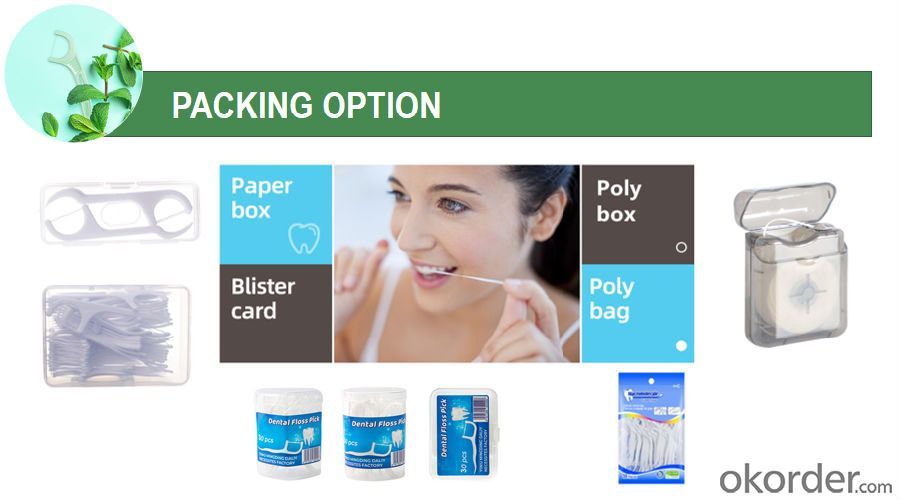

Many kinds of packaging options are available.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:Can medical plastics leach chemicals into the body?

- Yes, medical plastics can leach chemicals into the body.

- Q:Can medical plastic be safely used in geriatric applications?

- Yes, medical plastic can be safely used in geriatric applications. Medical-grade plastics are specifically designed and tested to meet the necessary standards for safety and compatibility with human health. They are often used in various medical devices and equipment, including those used in geriatric care, such as prosthetics, hearing aids, orthopedic implants, and assistive devices. These plastics are biocompatible, durable, lightweight, and resistant to bacteria, making them suitable and safe for use in geriatric applications.

- Q:How does medical plastic contribute to the development of biomaterials?

- Medical plastic plays a crucial role in the development of biomaterials by providing a versatile and customizable platform for creating various medical devices and implants. Its unique properties, such as biocompatibility, durability, and flexibility, allow for the fabrication of biomaterials that can mimic natural tissues and organs. Medical plastic enables the production of implants, prosthetics, and medical devices that are safe, reliable, and capable of integrating seamlessly with the human body, thereby advancing the field of biomaterials and improving patient outcomes.

- Q:How is medical plastic used in radiation therapy devices?

- Medical plastic is used in radiation therapy devices to provide a safe and precise delivery of radiation to the targeted area of the body. It is utilized in the construction of various components such as immobilization devices, patient positioning systems, and radiation shields. These plastics are designed to be compatible with radiation and ensure accurate treatment while minimizing the risk of side effects to patients.

- Q:What are the considerations for preventing leaching of chemicals from medical plastic?

- There are several key considerations for preventing leaching of chemicals from medical plastic. First and foremost, the selection of suitable plastic materials is crucial. Medical-grade plastics should be chosen carefully, ensuring they meet regulatory standards and have low levels of extractable substances. Proper testing and certification of the plastic materials should also be conducted to ensure their suitability for medical applications. Additionally, the manufacturing process plays a significant role in preventing chemical leaching. Strict control and monitoring of the production environment, including temperature and humidity, can help prevent the degradation of plastic and the release of chemicals. It is important to use techniques such as cleanroom manufacturing to minimize contamination and ensure the purity of the final product. Proper storage and handling of medical plastic products are equally important. Exposure to extreme temperatures, sunlight, or harsh chemicals can accelerate the leaching process. Therefore, storing medical plastic in controlled environments and following recommended storage guidelines can help prevent chemical leaching. Regular inspection and maintenance of medical plastic products are also necessary to ensure their integrity and prevent degradation over time. Monitoring for any signs of wear, cracks, or deterioration can help identify potential leaching risks and allow for timely replacements or repairs. Overall, a combination of careful material selection, stringent manufacturing processes, appropriate storage and handling, and regular maintenance are essential considerations for preventing the leaching of chemicals from medical plastic.

- Q:What are the alternatives to medical plastic in healthcare applications?

- There are several alternatives to medical plastic in healthcare applications, including glass, stainless steel, silicone, and biodegradable materials. Each of these alternatives offers unique properties and benefits, such as durability, chemical resistance, flexibility, and environmental friendliness. The choice of alternative material depends on the specific healthcare application and its requirements.

- Q:Can medical plastics be used in neurological applications?

- Yes, medical plastics can be used in neurological applications. They are often used in the development of various medical devices and implants for neurological surgeries and treatments. These plastics offer advantages such as biocompatibility, flexibility, and durability, making them suitable for applications like neurostimulation devices, cranial plates, and spinal implants.

- Q:How are medical plastics used in IV catheters?

- Medical plastics are commonly used in IV catheters to create the flexible tubing that allows for the safe and efficient administration of fluids and medications directly into a patient's bloodstream. These plastics are biocompatible and provide excellent performance characteristics such as flexibility, clarity, and resistance to kinking or collapsing. The use of medical plastics in IV catheters ensures patient comfort, reduces the risk of infections, and enables healthcare professionals to accurately monitor and deliver necessary treatments.

- Q:How do I erase labels affixed to glass or plastic?

- Hand cream. First, the surface of the printed products tear off, and then put some hand cream on the top, slowly thumb rub, rub for a while, you will be able to rub all the residual gum. Just a little slower. Hand cream is a kind of grease, which is not compatible with gum. Remove glue is to use this characteristic.

- Q:The use of various plastic materials?

- Suitable plastic products: tray, cups, cutlery, toothbrush, refrigerator cabinet, knob, lighting accessories, accessories, instrument mirror, packing box, stationeryABS acrylonitrile butadiene styrene copolymerABS acrylonitrile (chemical corrosion resistance, surface hardness of butadiene styrene) (toughness) (good processability, good dyeing weatherability, easy oxidation) with good comprehensive performance, high impact toughness and good mechanical properties, excellent heat resistance, oil resistance and chemical stability, stable size, easy to machine processing, surface plating, good electrical properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Portable Floss Roll Clean Environmentally Friendly Floss Roll For House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords