Floss Bamboo Charcoal Fiber Dental Floss Oral Care Tooth Clean Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Floss Bamboo Charcoal Fiber Dental Floss Oral Care Tooth Clean Floss

| Brand | OEM/Ok Floss |

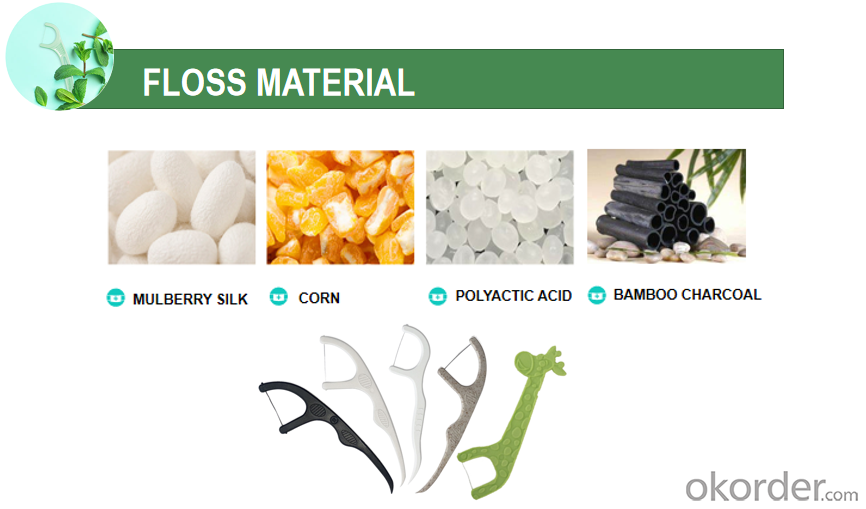

| Floss material | Charcoal /OEM |

| Floss length | 7.4*2.2cm、OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

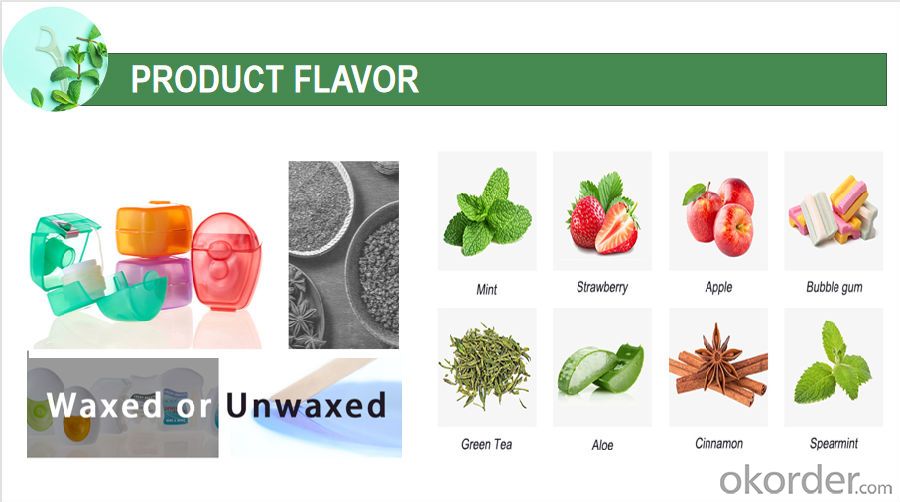

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Black |

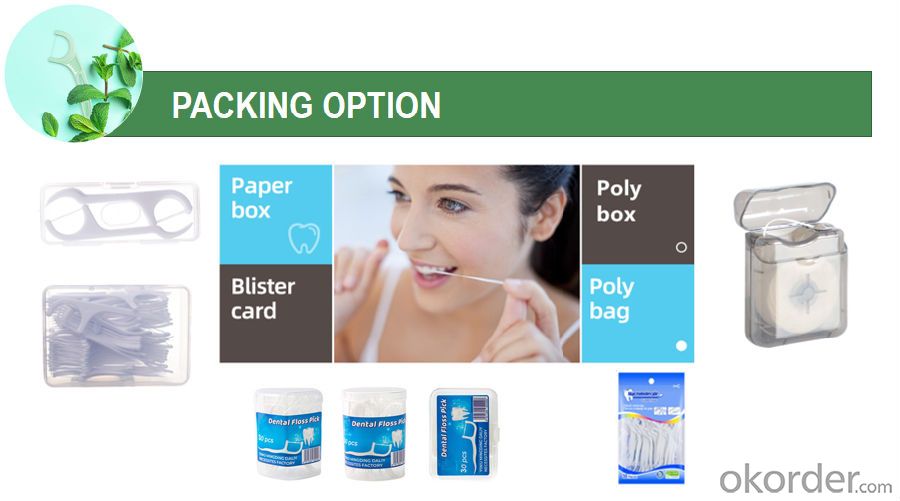

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Top quality dental floss for your business

Ok Floss help your oral care

Professional OEM/ODM provider

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

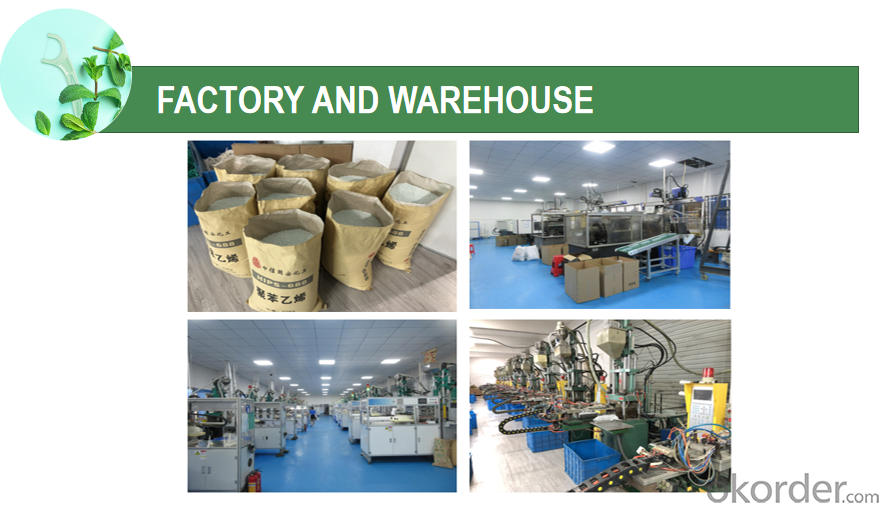

A: For the MOQ, the leading time is about 20-30 days.

- Q:Are there any potential risks associated with the use of recycled medical plastics?

- Yes, there are potential risks associated with the use of recycled medical plastics. These risks primarily stem from the potential presence of contaminants or residual substances in the recycled plastics, such as chemicals, pathogens, or traces of medications. These contaminants could compromise patient safety, cause adverse reactions, or contribute to the spread of infections. Additionally, the quality and integrity of recycled plastics may not meet the stringent standards required for medical devices or equipment, posing a risk in terms of durability and reliability. Therefore, thorough testing, strict quality control measures, and adherence to regulatory guidelines are necessary to mitigate these potential risks and ensure the safe use of recycled medical plastics.

- Q:How can medical plastic film be changed into hydrophilic material?

- The surface of the hydrophilic material is spread and can act by capillary action, and the water is sucked into the material from the water. The hydrophobic surface of the water can only be spread and the water penetrates into the capillary of the materialMaterials such as building materials, hydrophilic materials, cement, concrete, sand, stone, brick, wood and other materials, asphalt, paraffin wax and some plastic hydrophobic materialsHydrophilic materials are used more in bonding designs to make buildings more stable; hydrophobic materials are used as moisture-proof, waterproof and antiseptic materials, and hydrophilic materials are treated by surface treatment to reduce their water absorption

- Q:How does medical plastic help in preventing allergic reactions?

- Medical plastic helps in preventing allergic reactions by being hypoallergenic, meaning it has a low risk of causing allergic responses in patients. It is designed to be biocompatible, reducing the chances of irritation or inflammation when in contact with the skin or body tissues. Additionally, medical plastic is often free from common allergens such as latex, making it a safer alternative for individuals with known allergies.

- Q:What harm does plastic products do to people?

- Plastic bags really bring convenience to our life, but this temporary convenience brings long-term harm

- Q:What are the factors that affect the mechanical strength of medical plastics?

- The factors that affect the mechanical strength of medical plastics include the type and quality of the polymer used, the processing conditions during manufacturing, the presence of additives or fillers, the design and geometry of the medical device, and the environmental conditions to which the plastic is exposed.

- Q:Are there any potential risks associated with the release of microplastics from medical plastics?

- Yes, there are potential risks associated with the release of microplastics from medical plastics. These tiny plastic particles can accumulate in the environment and have the potential to enter the food chain, posing risks to both human health and ecosystem health. Studies have shown that microplastics can absorb and carry toxic chemicals, which can then be transferred to organisms upon ingestion. Additionally, the presence of microplastics in water bodies can have detrimental effects on marine life, disrupting their feeding and reproductive processes. Therefore, it is crucial to address and mitigate the release of microplastics from medical plastics to minimize these potential risks.

- Q:What are the considerations for selecting biocompatible medical plastic materials?

- When selecting biocompatible medical plastic materials, some key considerations include the material's compatibility with the human body, its mechanical properties, chemical resistance, sterilizability, and ease of processing. Additionally, factors such as biocompatibility testing, regulatory compliance, cost-effectiveness, and availability of the material in the required form and quantity should also be taken into account.

- Q:How does medical plastic help in medical packaging?

- Medical plastic helps in medical packaging by providing a sterile and protective barrier for medical devices, drugs, and equipment. It prevents contamination and maintains product integrity, ensuring the safety and efficacy of medical supplies. Additionally, medical plastics offer excellent flexibility, durability, and chemical resistance, making them suitable for various packaging applications.

- Q:How is medical plastic used in drug delivery patches?

- Medical plastic is used in drug delivery patches to provide a safe and effective method of administering medications. These patches are designed with a layer of medical-grade plastic that acts as a barrier, preventing the drug from escaping and ensuring controlled release. The plastic is biocompatible, meaning it is compatible with the human body, and can be easily applied to the skin. This allows for the slow and steady release of medications, ensuring a consistent dosage over a specific period of time.

- Q:Can medical plastic be used in bioartificial organs?

- Yes, medical plastic can be used in bioartificial organs. Medical-grade plastics are widely used in the development and manufacturing of bioartificial organs due to their biocompatibility, durability, and versatility. These plastics can be engineered to mimic the properties of human tissues and organs, enabling them to perform various functions within the bioartificial organs, such as providing structural support, acting as a scaffold for cell growth, or serving as a barrier for fluids or gases. Furthermore, medical plastics can be customized to meet specific requirements, making them a valuable material choice in the field of bioartificial organ development.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Floss Bamboo Charcoal Fiber Dental Floss Oral Care Tooth Clean Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords