Plastic Shredder Plastic crusher Plastic Crushing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

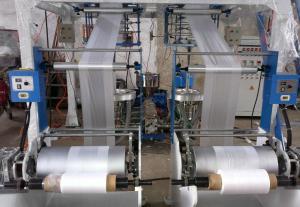

PC series Plastic Crusher

1.high quality tool steel, cutting-tool

2,using life is very long

3,easy operation

Character of PC series Plastic Crusher:

PC series plastic crusher absorbs domestic and foreign advanced technology; it has the rational design and repeated tests and keeps improving.

The machine has some features such as light in weight, low energy consumption, good quality, long life and easy to clean. PC series plastic crusher is suitable for smashing polystyrene, polypropylene, nylon, defective plastic products of injecting and extruding machine. If you change the suitable sieve and adjust the space among the blades, it can also be used in smashing the waste of various plastic such as PVC/PP/PE films, PET bottle, and plastic sheet and so on.

plastic crusher

It is a very important machine for recycling PP PE film, PET bottles and etc plastics.

Model | Crushing room dimension (mm) | Capacity (kg/h) | Motor power | Number of fixing blade | Number of rotating blade | Machine dimension (L*W*H)mm | Weight (KG) |

PC-180 | 190*195 | 30-80 | 2.2 | 2 | 6/9 | 680*530*800 | 250 |

PC-230 | 210*230 | 50-110 | 4 | 2 | 6 | 890*650*1102 | 300 |

PC-300 | 310*240 | 100-250 | 5.5 | 2 | 9 | 1050*800*1200 | 450 |

PC-400 | 410*255 | 200-450 | 7.5 | 2 | 12 | 1200*880*1330 | 550 |

PC-500 | 510*270 | 360-720 | 11 | 4 | 15 | 1380*1000*1380 | 650 |

PC-600 | 610*270 | 470-870 | 15 | 4 | 18 | 1380*1100*1500 | 750 |

PC-500H | 510*350 | 420-720 | 15 | 4 | 9 | 1400*1100*1600 | 1000 |

PC-600H | 650*425 | 600-870 | 22 | 4 | 12 | 1400*1130*1810 | 1800 |

PC-800 | 810*520 | 800-1000 | 30 | 4 | 15 | 2080*1500*2100 | 2000 |

PC-1000 | 1001*650 | 1000-1300 | 37 | 4 | 18 | 2080*1780*2100 | 3000 |

PC-400 for film | 410*255 | 50-150 | 7.5 | 2 | 6 | 1200*880*1330 | 550 |

PC-600 for film | 610*270 | 100-250 | 15 | 4 | 6 | 1330*1100*1500 | 750 |

- Q:Working video of aluminium crusher

- The aluminum is not high enough, the crusher needs to consider separating from other metal, no video can't be delivered here. It needs the equipment to call me!

- Q:Classification of equipment for plastics mills

- Plastic crusher in the injection molding industry, also known as: plastic crusher. There are three main categories:(1) hard plastic crusher, this machine is suitable for crushing all kinds of small and medium plastic sheets:1, ABS, PE, PP board and other plates crushed recovery;2. The rectangular feeding port designed for the crushing of plate materials is convenient for crushing long strip plates and improves work efficiency. The utility model can be matched with a suction fan and a storage barrel to form a plate crushing and recovering system, and the recycling efficiency can be more fully utilized;3, the use of sealed bearings, bearing rotation for a long time to maintain good; knife design is reasonable, the product even granules; knife stand heat shrinkable treatment, shape design beautiful and generous;

- Q:How many kinds of crusher are there? What are the main differences? Please explain them in detail

- Jaw crusher, impact crusher, cone crusher, hammer crusher, impact crusher, to roll crusher, composite crusher etc..

- Q:How should the plastic crusher blade be ground?

- Plastic crusher blades generally need to grind when it is relatively blunt

- Q:How much does a small plastic crusher cost?

- Small several thousand blocks, medium-sized ten thousand or twenty thousand, big thirty thousand or forty thousand have

- Q:How often does the plastic crusher get rid of the knife?

- Bolt tooth nut is not equipped with spring washer. It is easy to loose bolts

- Q:What material should be used for the plastic crusher screen?

- The grate below the plastic crusher is made of alloy.

- Q:How do you melt plastics?I would like to waste plastic (such as: pots, shells), melting and forming, as a useful equipment shell (such as: sound shell). But plastic is non crystal, how to melt like a crystal, please advise!

- It can be heated by plastic injection molding machine. The molten plastic is injected into the corresponding mold at higher pressure. After cooling and shaping, the product is removed

- Q:What kind of heating machine is better for the recycled plastics factory? How long does the crusher sink need to be cleaned?

- Are you talking about an extruder particle? If I heated it with coal

- Q:How much does it cost to process a ton of plastic bottles?

- Market analysis of broken plastic bottles for waste plastics bottlesA bottle of mineral water and other waste polyester plastics have emerged, this kind of products except mineral water, and transparent bottles, beverage bottles of coke, because of its large volume, light weight, it is difficult to transport, so local processing is an economical and practical new way. Among them, it is the simplest and feasible way to break, clean and process plastic fragments. Besides removing the fixed waste materials, it can create economic benefits of about 300 yuan per ton, and the market prospect is very impressive.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Shredder Plastic crusher Plastic Crushing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords