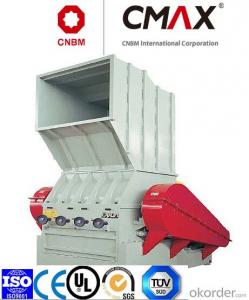

Low speed recycled plastic crusher

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Low speed recycled plastic crusher

1.Durable Low Speed Low Noise

2.Low dust

3.Run automatically

Low speed recycled plastic crusher

The leftover material of the injection mould machine and blow molding machine should be crushed and put back into charge port immediately.Doing in this way,we can achieve material recovery and assure the true quality of recovered material.

Features of Low speed recycled plastic crusher

1.Low-speed running,low energy consumptionj ,super low noise.

2.Coarse crushing and fine crushing at the same time.

3.Well-made crushed particle,no powder or dust.

4.No mesh screen,well-made particle.

5.Central segmentation design which assure easy cleaning.

6.Automatic discharging settings are optional for this machine.

Specifications of Low speed recycled plastic crusher

Model GMS-30

Power(kw) 2.2

Inlet size 250*290MM

R.P. M 36

Machine size 950*350*1230MM

Weight 230KG

Capacity 18-30kg/hr

Our work process

A. Before-sale

a. Introduce products and applications detain

b. Recommend suitable solution

c. Provide with reference in formation

d. Offer lab for test

B. During manufacturing

a. Provide with layout and engineering conditions

b. Inform the project processing status

c. Offer other documents

C. After-sale

a. Provide with installation ,commissioning and training

b. Register and record customer information

c. Offer spare parts

d. Provide with necessary technical support for new application

e. Visit customer regularly and correct information

Trade information of mid speed recycled plastic crusher

Trade Terms:FOB,CIF,EXW

Payment terms:T/T,Westem Umion,PayPal,,Escrow,MoneryGram

Delivery Time:7-20working days after deposit,3working days for inventory

Packing: According to the customer's requirment

Shipping:By sea

- Q:Working video of aluminium crusher

- Cans are mature aluminum, cooked aluminum or raw aluminum, there is no rigid target, once again cooked aluminum refers to the higher content of aluminum, more than 96% or so,

- Q:Classification of equipment for plastics mills

- (three) plastic pipe, plastic crusher:1, suitable for crushing all kinds of small and medium-sized plastic pipe, such as PE, PVC pipe, silicon core tube and other pipe crushing, recycling;2, for the tube material crushing and unique design of the round pipe type feeding mouth, easy to strip tube into grinding, improve work efficiency. The utility model can be provided with a suction fan, a storage barrel and a pipe crushing and recovering system, so as to give full play to the recovery efficiency;3, the use of sealed bearings, so that the rotation of the bearings for a long time to maintain good; knife design is reasonable, can make products into granules evenly; knife holder heat treatment, so that the shape of the design beautiful and generous.JHL series crusher main function:The utility model is used for crushing various soft and hard plastics, and the blocks, balls and strips of plastics are crushed into granules for recycling, thereby greatly improving the utilization ratio of plastics.JHL series crusher features:

- Q:How to calculate the crushing capacity of a coal crusher?What's the formula?

- What are the main factors that affect the work of the jaw crusher?Generally, the main factors affecting the operation of jaw crusher are meshing angle and RevolutionIs the angle between the meshing angle of moving jaw and fixed jaw. According to the 32 degree calculation of the maximum meshing angle up. The actual use are less than 25 degrees, generally 1820 degrees. The meshing angle is too large, would break up the ore out of the cavity, sand production line, resulting in injury or damage to other equipment. At the same time as the meshing angle increases (crushing ratio increase) decreased productivity. Adjust the size of the mouth of discharge, will change the size of the nip angle. In real life, to adjust the size of the mouth of discharge according to the ore granularity requirements. Therefore, to ensure product size requirements, as far as possible amplification of discharge mouth is reasonable. Gape size can be adjusted by adjusting the block, on the relation between the regulation of discharge should pay attention to broken mouth size ratio and productivity.

- Q:Plastic crusher is slow to eat. Why?

- Fixed, then remove the fixed knife grinding, so as to better the fixed knife.

- Q:What are the differences between plastic crushers and particle machines, as well as the amount of money needed to buy machines and running capital? How much do I have to do to make it work? Yes, there are machines to buy machines, washing machines and crushers, and so on. Is everything a set? How much is the set? I'll do that. I'll go to the manufacturer and find the Department in it. And how do I ask him if he accepts my plastic?

- Compress and extrude and make plastic granules of mung bean size for easy use. Manufacturing of recycled plastic particles must have plastic crusher and plastic granulator, equipment according to advanced level and quality requirements, the price varies greatly,

- Q:Points for attention of plastic recycling granulator

- 3, the main bearing room at both ends of the bearing parts burned, hand burning or noise, we should stop, repair and add butter. During normal operation, the bearing chamber butter once every 5-6 days.4, pay attention to find out the law of operation of the machine, such as: machine temperature, speed, speed, according to the situation, timely processing.5, the operation is stable, should pay attention to check the gap coupling agreement is too tight, to timely adjust some loose.

- Q:What's the difference between a domestic crusher and another crusher?

- According to the different manufacturing process, it can be divided into crawler mobile crushing station and tire mobile crushing station.

- Q:Is the waste plastics crusher harmful to the environment when it is produced?

- Low carbon, energy saving, low noise, tearing materials, recycling, and so on.It's the latest plastic shredder machine:

- Q:What type of crusher is good for heavy crusher?

- Heavy crusher can be widely used in all kinds of building aggregate, limestone, gypsum, shale and other compressive strength of less than 200Mpa, low abrasive material fragmentation

- Q:Plastic crusher blade easily broken, because what?

- Second, the brittleness of the tool's steel is only the main reason for the collapse;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Low speed recycled plastic crusher

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords