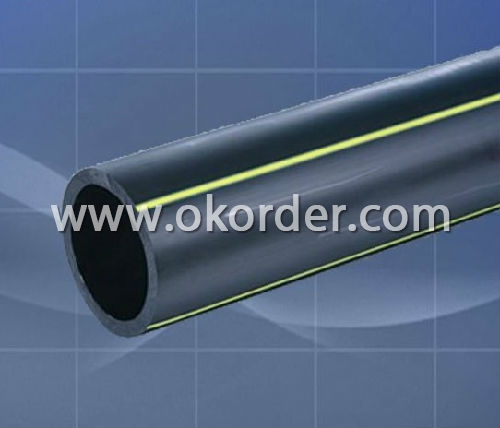

PE Gas Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meters m

- Supply Capability:

- 1000000 Meters m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of PE Gas Pipe :

Place of Origin | China (Mainland) |

Material | HDPE |

Specification | dn20~dn630 |

Length | 4m,5.8m,11.8m |

Thickness | Standard |

Standard | ISO4427, ISO4437 |

Raw Material | PE80, PE100 |

Color | Black, Blue |

Temperature | -40℃~60℃ |

Product Description of PE Gas Pipe:

Material: PE80/ PE100 (mainly PE 100 now).

Sizes: 20mm--630mm

SDR: SDR11, SDR13.6, SDR17, SDR21, SDR26, SDR33

Pressure: 0.4Mpa(PN4), 0.6Mpa(PN6), 0.8Mpa(PN8), 1.0Mpa(PN10), 1.25Mpa(PN12.5), 1.6Mpa(PN16)

Color: Black or others on request

Connection: Socket-fusion jointed, butt-fusion jointed , electron-fusion jointed, flange jointed

Standard: ISO4427, ISO4437, GB/T 13663-2000

Certification: ISO9001, ISO14001

Application: Water supply, Industries liquids transportation , sewage conduit

Identifies: black water pipe identifies the color at least three blue stripes, and evenly distributed along the pipe circumference

Advantage of PE Gas Pipe:

1. Non-toxic, no heavy metal additives, no fouling, not breed bacterium,

2. Corrosion resistant: PE is inert material and it can resist the corrosion of many chemical mediums, or electron chemical corrosion. except for few strong oxidants

3. High strength, good performance to resist the environmental stress cracking, good creep resistance.

4. Good flexibility: small diameters, PE pipe for water supply can be coiled and supplied for longer length, which saves a large number of fittings, PE pipe can be easily shifted according to requirement of the projects.

5. Light weight, simple safe and reliable welding technique, convenient construction and lower cost of the whole engineering,

6. Smooth interior wall, small water resistance, high flow capacity,

7. Long service life, up to 50 years under normal conditions.

8. Recyclable, benefit to the environment

- Q:Can composite pipes be used in chemical processing plants?

- Yes, composite pipes can be used in chemical processing plants. Composite pipes are known for their excellent chemical resistance, corrosion resistance, and durability. They can handle a wide range of chemicals and offer better performance compared to traditional metal pipes. Additionally, composite pipes are lightweight, easy to install, and require minimal maintenance, making them a suitable choice for chemical processing plants.

- Q:Are composite pipes suitable for oil and gas refineries?

- Yes, composite pipes are suitable for oil and gas refineries. Composite pipes offer numerous advantages such as excellent corrosion resistance, high strength-to-weight ratio, and durability, making them ideal for transporting various fluids, including oil and gas, in refinery operations. Their lightweight nature allows for easier installation, maintenance, and reduced transportation costs. Additionally, composite pipes can withstand extreme temperatures and pressure, ensuring the safe and efficient flow of oil and gas within the refineries.

- Q:Can aluminum plastic PPR composite pipe hold bending?

- So if PPR basically can not nest, then aluminum plastic PPR can not nest bending. Generally speaking, the hot melt connection can be bent, PE-RT, not aluminum plastic PPR.

- Q:Are composite pipes suitable for offshore applications?

- Yes, composite pipes are suitable for offshore applications. They offer numerous advantages such as corrosion resistance, high strength-to-weight ratio, and excellent fatigue performance, making them ideal for the harsh and corrosive offshore environments. Additionally, composite pipes are easy to install and require less maintenance compared to traditional metal pipes.

- Q:What is plastic composite pipe?

- Plastic composite pipe is usually made of several materials of composite pipes, such as PP and glass fiber composite

- Q:Can composite pipes be used for rainwater drainage systems?

- Yes, composite pipes can be used for rainwater drainage systems. Composite pipes are made of a combination of materials such as fiberglass, plastic, and resin, making them highly durable, corrosion-resistant, and lightweight. These properties make them suitable for various applications, including rainwater drainage systems, where they can effectively transport rainwater while withstanding the harsh environmental conditions. Additionally, composite pipes offer flexibility in design, allowing for easy installation and maintenance.

- Q:PP-R steel plastic composite pipe

- PP- plastic steel composite pipe has only carbon and hydrogen elements, and has no harmful toxic elements. It can be used not only for hot and cold water pipelines, but also for the Spring Festival drinking water system.

- Q:Are composite pipes resistant to soil settlement?

- Yes, composite pipes are generally resistant to soil settlement. The combination of materials used in composite pipes, such as fiberglass and resin, provide them with inherent strength and flexibility. This allows them to withstand soil settlement and ground movements without compromising their structural integrity.

- Q:Internal and external epoxy composite pipe, belong to plastic composite pipe?

- As a result of the heavy anti-corrosion modified epoxy resin belongs to thermosetting plastics, its coating has good temperature resistance, and can be used at 30 ~ 200 degrees centigrade for a long time, and does not burn. At the same time, with chemical corrosion resistant, resistant to corrosion, high temperature resistant and fire extinguishing agent, and the resistant wood crib fire protection water and anhydrous conditions or flame resistant properties, especially suitable for fire water, gas fire extinguisher. 3, epoxy water (gas) inside and outside the plastic pipe is combined with plastic products, the plastic pipe with high strength, good rigidity, high pressure resistance strength.

- Q:How to connect the steel plastic composite pipe?

- Method for connecting steel plastic composite pipe:Steel plastic composite pipe is divided into two kinds of plastic and plastic lining, if the design is lined with plastic coated steel pipe can be used instead, but if the design is not available to replace the plastic lining plastic pipe. The general connection mode is PSP steel plastic composite pipe. The specification is thread connection within one hundred millimeters; the groove connection is between one hundred and two hundred; and more than two hundred is flange welding. Sometimes it is necessary to determine the method according to the actual pressure requirement.

1. Manufacturer Overview |

|

|---|---|

| Location | Wuxi,China |

| Year Established | 1998 |

| Annual Output Value | US$1.5 Million - US$2 Million |

| Main Markets | South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia |

| Company Certifications | NONE |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered;Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

PE Gas Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meters m

- Supply Capability:

- 1000000 Meters m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords