Ms Light Steel Rail Q235, 55Q

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Ms Light Steel Rail Q235, 55Q

Production Standard: GB11264-89

Material: Q235, 55Q

Grade | Element(%) | ||||

C | Mn | S

| P

| Si

| |

Q235 |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

55Q | 0.50—0.60 | 0.70—1.00 | ≤0.050 | ≤0.045 | 0.15-0.35 |

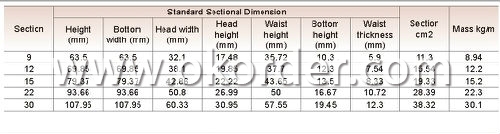

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6M, 8M, 10M, 12M or as the requriement

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Ms Light Steel Rail Q235, 55Q

Light Steel Rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line, for example:

railway, subway, transportation track, express, curve way, tunnel way.

Package & Delivery of Ms Light Steel Rail Q235, 55Q

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Ms Light Steel Rail Q235, 55Q

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Ms Light Steel Rail Q235, 55Q

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

- Q:How are steel rails used in railway electrification systems?

- Steel rails are a crucial component in railway electrification systems as they serve as the primary conductors of electrical current. These rails are specifically designed to provide a reliable path for the flow of electricity, enabling the efficient transfer of power from the power supply to the trains. In railway electrification systems, the steel rails act as the positive conductor, carrying the direct current (DC) to power the electric locomotives or trains. The rails are installed in a continuous track configuration, ensuring a consistent and uninterrupted power supply throughout the railway network. To facilitate electrical conductivity, the steel rails are typically made of high-quality steel that has excellent electrical conductivity properties. They are also manufactured with precision to ensure uniformity and consistency in electrical resistance across the entire railway network. The electrification system is based on the principle of using a pantograph, which is mounted on the roof of the train, to collect electricity from the overhead lines or catenary wires. As the train moves along the tracks, the pantograph maintains contact with the overhead lines, allowing the electrical current to flow from the wires to the steel rails. The steel rails not only serve as conductors but also provide mechanical support to the trains. They ensure smooth movement of the trains by guiding the wheels along the track and distributing the weight of the train evenly. This combination of electrical conductivity and mechanical stability makes steel rails an essential component in railway electrification systems. Overall, steel rails play a critical role in railway electrification systems by providing a reliable path for the flow of electricity, enabling the efficient transfer of power to the trains. They are designed to ensure both electrical conductivity and mechanical stability, making them indispensable for the smooth and reliable operation of electric trains in modern railway networks.

- Q:How do steel rails contribute to train energy consumption?

- Steel rails contribute to train energy consumption in several ways. Firstly, steel rails provide a smooth and stable track surface for trains to travel on. This reduces rolling resistance, which is the force that opposes the motion of the train. A smooth track with minimal friction allows the train to move more easily and efficiently, requiring less energy to overcome resistance and maintain its speed. Secondly, steel rails help distribute the weight of the train across a larger area, which reduces the pressure exerted on the track. This prevents excessive wear and damage to both the train and the track, ensuring that the train can continue to operate efficiently. By minimizing the need for repairs and maintenance, steel rails indirectly contribute to lower energy consumption. Furthermore, steel rails are also responsible for guiding the train along its route. The precise alignment and stability provided by the rails ensure that the train stays on track and does not deviate from its intended path. This reduces the energy wasted on unnecessary lateral movements or corrections, allowing the train to maintain its momentum and minimize energy consumption. Lastly, steel rails play a crucial role in the braking system of trains. The high friction coefficient between the steel rails and train wheels allows effective braking, enabling the train to slow down or come to a complete stop when necessary. By providing a reliable braking mechanism, steel rails ensure safety while also reducing the need for excessive braking distances, which would otherwise consume additional energy. In summary, steel rails contribute to train energy consumption by reducing rolling resistance, distributing weight, guiding the train's path, and facilitating efficient braking. These factors collectively help trains operate more efficiently, requiring less energy to overcome resistance and maintain their speed.

- Q:What are the different types of rail fastenings used in high-speed steel rail installation?

- There are several types of rail fastenings used in high-speed steel rail installation, including elastic rail clips, bolted rail clips, and pandrol clips. These fastenings are designed to securely hold the rails in place while allowing for some degree of flexibility to accommodate changes in temperature and load.

- Q:What is the role of steel rails in reducing train derailments?

- The role of steel rails in reducing train derailments is crucial. Steel rails provide a sturdy and reliable track structure that can withstand heavy loads and maintain stability, ensuring that trains stay on the designated path. The durability and strength of steel rails help prevent shifts or deformations that could lead to derailments. Additionally, the precise design and alignment of the rails allow for smooth and safe train operations, minimizing the risk of accidents.

- Q:What are the factors that determine the quality of steel rails?

- There are several factors that determine the quality of steel rails. Firstly, the composition and purity of the steel used in the rails play a crucial role. The presence of impurities and undesirable elements can weaken the rail's strength and durability. High-quality steel rails are made from alloys that have a precise combination of elements, such as carbon, manganese, silicon, and trace amounts of other elements, which provide the desired strength and resilience. Secondly, the manufacturing process and techniques employed in producing the steel rails are essential. The rails should be rolled and forged with precision to ensure uniformity, proper shape, and a smooth surface finish. Any defects or irregularities during the manufacturing process can impact the rail's structural integrity and performance. Thirdly, the heat treatment and quenching processes are critical in determining the quality of steel rails. Proper heat treatment enhances the rail's hardness, strength, and resistance to wear and fatigue. Quenching, which involves rapid cooling of the rail, helps in achieving the desired microstructure and properties. These processes need to be carefully controlled to avoid any issues like brittleness or softness. Additionally, the design and dimensions of the rail also contribute to its quality. The rail's cross-sectional shape, size, and weight distribution need to be optimized to handle the required loads, provide stability, and minimize wear and tear. The rail's profile should be designed to ensure smooth movement of the train wheels and reduce the risk of derailment or excessive vibrations. Furthermore, various performance tests, such as hardness, tensile strength, resilience, and wear resistance, are conducted to assess the quality of steel rails. These tests help in determining if the rails meet the specified standards and can withstand the expected loads and environmental conditions. Lastly, maintenance and regular inspections of the steel rails are crucial to maintain their quality. Continuous monitoring of the rail's condition, including detecting any cracks, wear, or deformations, is essential to prevent accidents and ensure smooth train operations. In conclusion, the quality of steel rails is influenced by factors such as the composition of the steel, manufacturing processes, heat treatment, rail design, performance tests, and maintenance practices. All these factors work together to ensure that the steel rails are strong, durable, and capable of withstanding the demanding conditions of railway transportation.

- Q:Are steel rails susceptible to temperature changes?

- Yes, steel rails are susceptible to temperature changes. Steel is a material that expands when exposed to high temperatures and contracts when exposed to low temperatures. This phenomenon is known as thermal expansion and contraction. When steel rails are subjected to hot temperatures, they expand, which can cause them to buckle or warp. This can lead to track misalignment and potential derailments if not addressed promptly. Conversely, in cold temperatures, steel rails contract, which can result in gaps between the rail sections. This can affect the stability of the tracks and increase the risk of accidents. To mitigate the effects of temperature changes, rail systems often employ various methods. For instance, rail joints are designed with expansion gaps to accommodate thermal expansion. Additionally, rail fasteners and clips are used to secure the rails tightly to the sleepers, allowing some flexibility for expansion and contraction. Furthermore, in extreme temperature conditions, such as during heatwaves or cold spells, rail maintenance and inspections are typically increased to identify and address any potential issues promptly. Overall, while steel rails are susceptible to temperature changes, proper design, maintenance, and monitoring measures can minimize the impact and ensure the safe and efficient operation of rail systems.

- Q:Does the crane use the touch wire or the rail directly?

- The sliding rail line (fixed part, and is connected to a power supply rail, often by a single 4m/ or 6 meters long root / root connected together), the collector (or within the sliding part, can slide wire track and sliding contact with the copper strip to take power, for the collector is connected with the mobile motor).

- Q:How do steel rails handle heavy rainfall and flooding?

- Steel rails are designed to withstand heavy rainfall and flooding. They are constructed with materials that are resistant to corrosion and erosion caused by water, ensuring their durability even in extreme weather conditions. Additionally, the design of the railway track includes proper drainage systems and slope gradients to facilitate the smooth flow of water and prevent water accumulation. This helps to maintain the structural integrity of the rails and ensures safe and reliable train operations during heavy rainfall and flooding.

- Q:How are steel rails inspected for cracks?

- Steel rails are inspected for cracks through a combination of visual inspections and non-destructive testing techniques. Visual inspections involve trained inspectors visually examining the rails for any visible cracks, fractures, or other defects. Non-destructive testing techniques like ultrasonic testing, magnetic particle inspection, and eddy current testing are also used to detect cracks that may not be visible to the naked eye. These techniques help ensure the safety and integrity of the steel rails by identifying any potential cracks or flaws that could compromise their structural strength.

- Q:Can steel rails be bent or shaped to fit different track designs?

- Yes, steel rails can be bent or shaped to fit different track designs. Steel is a highly malleable material, which means it can be easily bent, twisted, or shaped without breaking. Rail manufacturers have the capability to customize steel rails, allowing them to be shaped according to specific track designs. This flexibility in shape allows for the creation of curved tracks, switches, and various other track configurations. Specialized equipment, such as hydraulic presses, are used to apply controlled pressure and shape the steel rails. However, it is important to note that the bending process must be carried out carefully and precisely to ensure the rails maintain their structural integrity and can safely support the weight of trains.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong, China |

| Year Established | 1993 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Exported to Thailand, India, Brazil, Egypt, Saudi Arabia, Japan, Vietnam and many other countries and regions |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Qingdao; Rizhao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Ms Light Steel Rail Q235, 55Q

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords