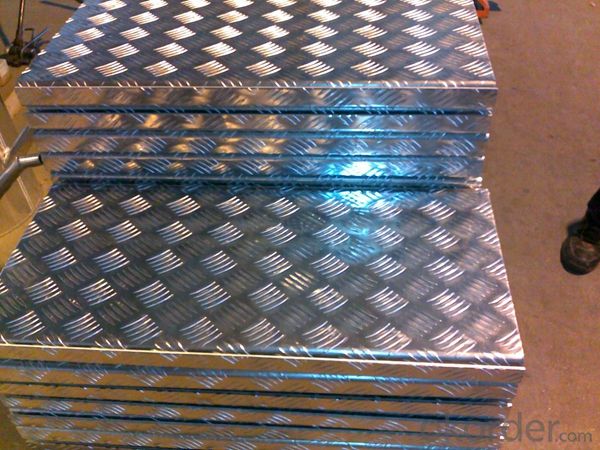

Mill Finish Embossed Diamond Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Mill Finish Embossed Diamond Aluminum Sheet

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Embossed Diamond Aluminum Sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Embossed Diamond Aluminum Sheet

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Mill Finish Embossed Diamond Aluminum Sheet

6. Package and shipping of Mill Finish Embossed Diamond Aluminum Sheet

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:How do aluminum sheets perform in terms of electrical insulation?

- Aluminum sheets have poor electrical insulation properties as they are highly conductive materials.

- Q:Can aluminum sheets be anodized with custom designs?

- Yes, aluminum sheets can be anodized with custom designs. Anodizing is an electrochemical process that enhances the natural oxide layer on the surface of aluminum, making it more durable and corrosion-resistant. During this process, different patterns and designs can be added to the aluminum sheet by masking off certain areas and exposing others to the anodizing solution. This allows for custom designs to be etched or dyed onto the surface, creating unique and personalized finishes. Anodized aluminum sheets with custom designs are commonly used in various industries, including architecture, automotive, and electronics, to achieve aesthetic and functional requirements.

- Q:Are aluminum sheets suitable for medical applications?

- Yes, aluminum sheets are suitable for medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for medical equipment and devices. It is commonly used in the production of medical instruments, diagnostic imaging systems, and surgical trays. Additionally, aluminum sheets can be sterilized easily, further enhancing their suitability for medical applications.

- Q:Can aluminum sheets be anodized for aesthetic purposes?

- Yes, aluminum sheets can be anodized for aesthetic purposes. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, which can be further enhanced with various colors and finishes for aesthetic appeal.

- Q:Are aluminum sheets suitable for outdoor applications?

- Aluminum sheets are a great choice for outdoor applications. They are durable and resistant to corrosion, which makes them perfect for outdoor environments. They can withstand different weather conditions like rain, snow, and sunlight without getting damaged or losing their strength. Furthermore, aluminum sheets can be coated or painted to make them more resistant to fading, scratching, and other types of wear and tear. This makes them suitable for various outdoor projects like roofing, siding, signage, and decorative elements. Additionally, aluminum is lightweight and easy to shape, making installation and customization a breeze. In summary, aluminum sheets are a dependable and long-lasting option for outdoor projects.

- Q:On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- if a candle is 1000 degrees u can melt aluminum with it, it wont happen straight away, you have to give the metal a long time to heat up as it conducts heat it will take ages, you will prob let go or get bored before the metal has chance to heat up

- Q:Could induction heating fuenace be packaged with aluminum foil as insulation material?

- Aluminum foil can’t be used for heat retaining, it’s unsafe and hasn’t good efficiency. In this case, advice you use refractory cement to knot the coil and connect porcelain tube in the middle. It will Largely reduce the energy consumption produced by heat radiation.

- Q:The corrosion of the aluminum sheet that I request is friction during operation, not the surface of the container after the passivation of the surface of the container containing sulfuric acid. I'd like to use the evaporating plate, the evaporator fin and so on for the cooling in the quick freezing equipment. The ice of ice making machine is attached to the aluminum plate after anodic oxidation or passivation. When it is peeled off, it will cause friction to the surface of the aluminum plate and block the passivation layer, which will make the aluminum plate easier to corrode.

- Aluminum does not need to be processed to prevent corrosion, and the formation of dense oxide film with oxygen can prevent corrosion

- Q:How do you join two aluminum sheets together?

- One common method to join two aluminum sheets together is through welding. This involves melting the aluminum at the joint using various techniques like TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding, and then allowing it to cool and solidify, effectively fusing the two sheets together. Additionally, other methods like riveting, adhesive bonding, or using mechanical fasteners like screws or bolts can also be used to join aluminum sheets. The choice of method depends on the specific application and desired outcome.

- Q:A construction worker uses a steel tape to measure the length of an aluminum support column. If the measured length is 17.7 m when the temperature is 21.2°C, what is the measured length when the temperature rises to 35.4°C? (Note: Do not neglect the expansion of the steel tape. Give your answer to three decimal places.)I am really confused... Could someone solve it for me with a step-by-step explanation? Thank you so much.

- Aluminum cases offer better heat control than steel cases. Heat generating from the motherboard is absorbed by the case and then dissipated to the air. Aluminum dissipates heat better than steel. As for your question regarding ATX cases, have you tried using the barebone kits from Shuttle? Shuttle uses small form factor(i.e. small footprint). They are roughly the size of a shoe box.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mill Finish Embossed Diamond Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords