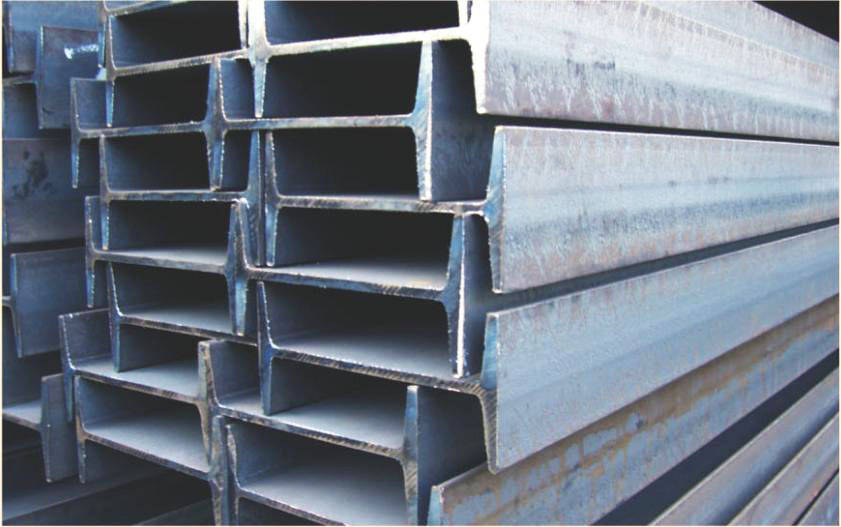

Mild Steel I-Beam Steel Profiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Mild Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Mild Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Brand: Jinding

Grade: SS400 – SS490

Standard: JIS, ASTM, GB

Packaging: Export packing, nude packing, bundled

Place of Origin: Hebei, China

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:How are steel I-beams used in commercial construction?

- Steel I-beams are commonly used in commercial construction due to their strength, versatility, and cost-effectiveness. These beams are typically made of high-quality steel and are shaped like the letter "I," with a horizontal top flange, a vertical web in the middle, and another horizontal bottom flange. In commercial construction, steel I-beams are primarily used as structural components to support the weight of the building and transfer loads to the foundation. They are commonly used for constructing floors, roofs, and walls, as well as in the framework of bridges and other large structures. One of the main advantages of steel I-beams is their ability to span long distances while supporting heavy loads. The shape of the I-beam provides excellent strength-to-weight ratio, allowing it to carry significant loads without excessive weight. This makes it possible to create large open spaces within commercial buildings, such as warehouses, shopping centers, and industrial facilities, without the need for additional columns or supports. Steel I-beams also offer flexibility in design and construction. They can be customized to meet specific structural requirements, such as the desired span, load capacity, and overall design aesthetics. This adaptability allows architects and engineers to create efficient and functional commercial spaces while ensuring structural integrity. Additionally, steel I-beams are highly durable and resistant to fire, corrosion, and pests, making them suitable for long-term use in commercial buildings. They require minimal maintenance compared to other construction materials, reducing overall lifecycle costs. In summary, steel I-beams are essential components in commercial construction due to their strength, versatility, and cost-effectiveness. They provide structural support, enable the creation of large open spaces, and offer design flexibility. Their durability and low maintenance requirements make them an ideal choice for long-lasting and efficient commercial buildings.

- Q:Can steel I-beams be used for billboard structures?

- Yes, steel I-beams can be used for billboard structures. Steel I-beams are commonly used in construction due to their strength and durability. They provide excellent load-bearing capabilities and can withstand heavy wind and weather conditions, making them suitable for supporting large billboards. Additionally, steel I-beams can be easily fabricated and assembled, allowing for efficient installation and maintenance of billboard structures.

- Q:Are steel I-beams suitable for earthquake-prone areas?

- Yes, steel I-beams are generally considered suitable for earthquake-prone areas. Steel is a strong and ductile material that can withstand the dynamic forces and vibrations caused by earthquakes. I-beams, specifically, provide structural stability and resistance to bending and shearing forces, making them effective in earthquake-resistant construction. Additionally, steel is a lightweight material, which allows for flexible designs and easier transportation, making it a popular choice in seismic zones. However, it is important to consider other factors like proper engineering, construction techniques, and adherence to seismic codes and regulations to ensure the overall safety and resilience of structures in earthquake-prone areas.

- Q:Can steel I-beams be used in retail or shopping center construction?

- Yes, steel I-beams can be used in retail or shopping center construction. Steel I-beams are commonly used in commercial construction projects due to their strength, durability, and versatility. They provide structural support for the building, allowing for larger open spaces and flexible design options. Additionally, steel I-beams are fire-resistant, which is an important safety feature in retail and shopping center construction. Overall, steel I-beams are an excellent choice for retail or shopping center construction due to their structural integrity and ability to meet the specific needs of these types of buildings.

- Q:Can steel I-beams be used in residential remodeling or addition projects?

- Yes, steel I-beams can be used in residential remodeling or addition projects. They are commonly used to provide structural support in various aspects of residential construction, such as for creating open floor plans, supporting heavy loads, or spanning large distances. Steel I-beams offer strength, durability, and versatility, making them a popular choice in residential construction.

- Q:Can steel I-beams be used for industrial platforms or catwalks?

- Yes, steel I-beams can certainly be used for industrial platforms or catwalks. Steel I-beams are known for their strength and durability, making them an excellent choice for such applications. They are capable of supporting heavy loads and can withstand the constant foot traffic and other industrial activities typically seen on platforms or catwalks. Additionally, steel I-beams can be easily customized to meet specific design and structural requirements, allowing for efficient and safe construction of industrial platforms or catwalks.

- Q:What are the factors to consider when designing steel I-beams for heavy machinery support?

- When designing steel I-beams for heavy machinery support, several factors need to be considered. These include the weight and dimensions of the machinery, the load capacity requirements, the span length, the type and intensity of the expected loads, the available space for installation, the material properties of the steel, and the desired level of structural safety. Additionally, factors such as potential vibration, impact, or dynamic forces should also be taken into account to ensure the beams can withstand the demands of heavy machinery support efficiently and safely.

- Q:Can steel I-beams be used for pharmaceutical facilities?

- Pharmaceutical facilities can indeed utilize steel I-beams. These beams are frequently employed in construction for their robustness, longevity, and ability to bear heavy loads. In pharmaceutical facilities, where there is a need for various weighty equipment, machinery, and storage systems, steel I-beams offer the vital structural support. Furthermore, steel I-beams possess resistance to fire, pests, and chemical damage, rendering them an excellent choice for pharmaceutical facilities that demand strict adherence to safety and cleanliness standards. Additionally, steel I-beams can be tailored to meet specific design requirements, enabling flexibility and efficient utilization of space in pharmaceutical facilities. In summary, steel I-beams are a dependable and pragmatic option for the construction of pharmaceutical facilities.

- Q:Can steel I-beams be used in residential roof structures?

- Yes, steel I-beams can be used in residential roof structures. They provide strength, durability, and allow for larger open spaces without the need for additional support columns.

- Q:What are the common methods for joining steel I-beams?

- The common methods for joining steel I-beams include welding, bolting, and using specialized connectors such as beam brackets or cleats.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mild Steel I-Beam Steel Profiles

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords