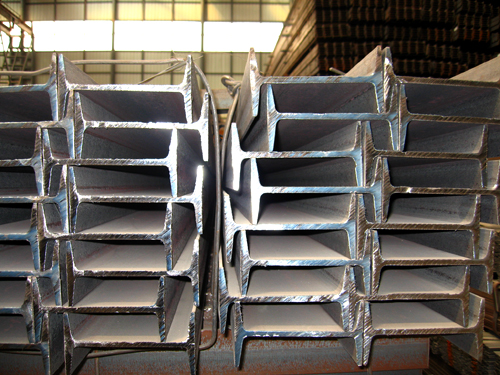

Metal Structure Steel I-beam High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 4000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Structural Steel I-Beam

OKorder is offering High Quality Structural Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Structural Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Grade: Q235B, SM490, SS400, Q235B, Q345, Q345B

Production Process: Rolling cross-section

Dimensions:

Leg Height: 46 – 220mm

Depth: 50 – 180mm

Thickness: 4.5 – 17mm

Length: 6m – 12m

Production: 500 tons/month

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q:The difference between I-beam i40a and i40b

- The difference between I-beam i40a and i40b:I40b is thicker than grade i40a i-beam.I40 class a weighs 67. 598 kg per metre.I40b 73 - 878 kg weight per meter.

- Q:How do engineers determine the required size of a steel I-beam for a specific application?

- Engineers determine the required size of a steel I-beam for a specific application by considering various factors such as the load it needs to support, the span it needs to cover, and the desired deflection limits. They analyze the structural requirements using mathematical formulas, computer simulations, and industry standards to ensure the I-beam can safely withstand the anticipated forces and maintain the desired level of structural integrity.

- Q:What is the allowable stress for 40B I-beam?

- Ordinary I-beam, light I-beam flange is variable cross-section, by web plate thickness, external thin; H steel: HW, HM, HN, HEA, HEB, HEM and so onOrdinary I-beam, lightweight I-beam has formed the national standard, the common 10# I-beam is equivalent to the Internet I100 (such as 10# also channel equivalent channel (U100) for the implementation of the standards of different countries, which have subtle differences in their specifications)

- Q:Can I ask the steel structure of my family to do this? Decoration company in order to save costs, with the I-beam in the load wall at both ends, in the middle with channel welding

- I-beam uses 12 centimeters and 16 centimeters, that depends on how long your span is, and how much the steel beam is around when the ceramsite is mixed. The data is the focus of judgment, not by sound.

- Q:Can steel I-beams be used for healthcare facilities?

- Healthcare facilities can indeed utilize steel I-beams. These beams, renowned for their strength and durability, are commonly employed in construction and can serve a multitude of purposes, including healthcare facilities. They offer exceptional structural support and can be used to frame walls, floors, and roofs, ensuring the stability and integrity of the building. Moreover, steel I-beams possess fire-resistant properties, a vital attribute in healthcare facilities where safety is paramount. Additionally, steel is a sustainable and recyclable material, aligning perfectly with the burgeoning trend of green building practices in the healthcare industry. All in all, steel I-beams present a reliable and pragmatic choice for the construction of healthcare facilities.

- Q:Can steel I-beams be used in industrial facilities?

- Yes, steel I-beams are commonly used in industrial facilities for their strength, durability, and load-bearing capabilities. They provide structural support for overhead cranes, mezzanines, platforms, and heavy equipment, making them a reliable choice for industrial construction.

- Q:What's the minimum specification for I-beam?

- I-beam is mainly divided into ordinary I-beam, light I-beam and H steel three.

- Q:What are the different types of steel I-beam connections for mezzanine floors?

- There are several different types of steel I-beam connections commonly used for mezzanine floors. Some of the most popular options include bolted connections, welded connections, and moment connections. Bolted connections involve using bolts and nuts to secure the beams together, making it easy to disassemble and reconfigure if needed. Welded connections involve welding the beams together, creating a strong and permanent connection. Moment connections are designed to resist bending moments and provide additional stability to the structure. Each type of connection has its own advantages and considerations, and the choice depends on the specific requirements and design of the mezzanine floor.

- Q:How do steel I-beams contribute to the overall energy efficiency of a building?

- There are several ways in which steel I-beams contribute to the overall energy efficiency of a building. To begin with, steel is an incredibly durable and long-lasting material. I-beams made of steel possess a high level of structural integrity, enabling them to bear the weight of the building and withstand various external forces over time. This durability reduces the need for frequent repairs or replacements, resulting in long-term cost and energy savings. In addition, steel I-beams are both lightweight and remarkably strong, allowing for the construction of larger open spaces and taller buildings. This characteristic is particularly advantageous for energy efficiency since it permits an increased amount of natural light to enter the building. By maximizing the utilization of natural light, the need for artificial lighting during the day is diminished, leading to reduced energy consumption. Furthermore, steel is an exceptionally recyclable material. At the end of their lifespan, steel I-beams can be effortlessly recycled, which lessens the environmental impact of construction projects. The recycling process necessitates significantly less energy compared to the production of new steel, further enhancing the overall energy efficiency of the building. Moreover, steel I-beams are frequently used in conjunction with other energy-efficient building materials, such as insulation. These I-beams function as a structural framework for the insulation, preventing the loss of heat or cool air from the building. This helps to maintain a consistent indoor temperature, reducing reliance on heating and cooling systems, and ultimately minimizing energy consumption. In conclusion, steel I-beams play a pivotal role in improving the energy efficiency of a building. Their durability, lightweight design, recyclability, and compatibility with energy-efficient materials all contribute to reducing energy consumption, promoting sustainability, and improving the overall environmental performance of the structure.

- Q:Do steel I-beams require any special maintenance?

- Yes, steel I-beams do require regular maintenance to ensure their structural integrity and longevity. This includes inspecting for signs of corrosion, checking for any cracks or damage, and applying protective coatings or treatments to prevent rust. Additionally, proper cleaning and lubrication of any moving parts or connections is necessary. Regular maintenance ensures the optimal performance and safety of steel I-beams.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Metal Structure Steel I-beam High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 4000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords