All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

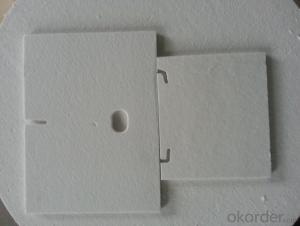

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials resist spalling from molten metal splash?

Refractory materials resist spalling from molten metal splash through their unique properties and design. They are specifically engineered to have high melting points and excellent thermal shock resistance, which means they can withstand extreme temperatures without cracking or breaking. Additionally, refractory materials have low thermal conductivity, preventing rapid heat transfer and minimizing the risk of spalling. Their composition and structure also play a crucial role in their resistance to spalling, as they are often made from ceramic fibers or aggregates that can absorb the energy from the molten metal splash and distribute it more evenly, reducing the likelihood of spalling.

What are the refractory materials used in the chemical processing industry?

Refractory materials used in the chemical processing industry include alumina, silica, magnesia, zirconia, and chrome oxide.

What is the role of refractory materials in the mining industry?

Refractory materials in the mining industry play a crucial role in providing protection and durability to high-temperature equipment and structures used in various mining processes, such as smelting, roasting, and refining. These materials are designed to withstand extreme heat, chemical reactions, and mechanical stress, ensuring the longevity and efficiency of mining operations.

Wholesale Refractory Materials from supplier in Algeria

Whether you are in need of refractory bricks, castables, mortars, or any other refractory materials, we have a wide variety of high-quality products to meet your specific requirements. Our team of experts is dedicated to providing excellent customer service and ensuring that you receive the right materials for your project.

In addition to our comprehensive product range, we also offer sales and quotation services to help you find the best solution for your budget. Our team will work closely with you to understand your needs and provide competitive pricing options.

Furthermore, we understand the importance of technical support in the successful implementation of refractory materials. Our experienced technicians are available to provide guidance and assistance throughout the entire process, from material selection to installation and maintenance.

As a subsidiary platform of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This allows us to stay up-to-date with the latest industry trends and technologies, ensuring that we can provide you with valuable insights and expertise for your projects in Algeria.

Whether you are working on a small-scale project or a large industrial facility, our team is committed to delivering high-quality refractory materials and excellent service to meet your needs. Contact us today to discuss your requirements and discover how we can assist you in your refractory materials procurement journey in Algeria.

In addition to our comprehensive product range, we also offer sales and quotation services to help you find the best solution for your budget. Our team will work closely with you to understand your needs and provide competitive pricing options.

Furthermore, we understand the importance of technical support in the successful implementation of refractory materials. Our experienced technicians are available to provide guidance and assistance throughout the entire process, from material selection to installation and maintenance.

As a subsidiary platform of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This allows us to stay up-to-date with the latest industry trends and technologies, ensuring that we can provide you with valuable insights and expertise for your projects in Algeria.

Whether you are working on a small-scale project or a large industrial facility, our team is committed to delivering high-quality refractory materials and excellent service to meet your needs. Contact us today to discuss your requirements and discover how we can assist you in your refractory materials procurement journey in Algeria.

Hot Search

- Monolithic Refractories in Kyrgyzstan

- Ceramic Fiber Products in Eritrea

- Refractory Bricks in Mauritius

- Raw Materials For Refractory in Romania

- Refractory Bricks in Israel

- Monolithic Refractories in Bulgaria

- Monolithic Refractories in Netherlands

- Ceramic Fiber Products in Belarus

- Refractory Bricks in Comoros

- Raw Materials For Refractory in Kiribati