Manufacture Corrugated Metal Roof Sheet for Houses

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

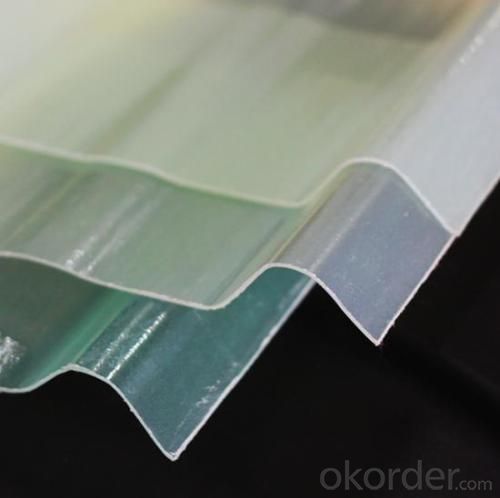

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Cold rolled sheet has superb sheet shape and surface quality with good flatness and surface finish. The surface of the cold sheet is clean and bright and easy for coating. The varieties of cold rolled sheet are widely used in galvanized substrates, home appliances, tubing, automobiles, building, enamels and other industries.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

SPECIFICATION

| Products Name | Manufacture corrugated metal roof / zinc roof / roofing sheet for houses |

THICKNESS | 0.14-0.5MM |

WIDTH | 765MM-->665MM 900MM-->800MM 1000MM-->900MM |

ALUZINC | ALUZINC ROOFING CAN BE SUPPLIED. |

MATERIAL | SGCC,DC51D,DX51D,DX52D |

SPANGLE | ZERO, REGULAR, NORMAL,BIG SPANGLE. |

SURFACT TREATMENT | CHROMATED, OILED, NON-OILED, DRY. |

HARDNESS | SOFT, HARD, FULL HARD. |

PICTURES

- Q:Can FRP roofing panels be used for commercial signage or advertising displays?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for commercial signage or advertising displays. FRP panels are lightweight, durable, and weather-resistant, making them an excellent choice for outdoor signage. Their smooth surface allows for high-quality printing or vinyl graphics to be applied, creating eye-catching displays. Additionally, FRP panels can be easily cut and shaped to meet specific design requirements, making them versatile for various signage applications. Their long lifespan and low maintenance needs also make them a cost-effective option for commercial signage or advertising displays.

- Q:Are FRP roofing panels compatible with different gutter systems?

- Yes, FRP roofing panels are compatible with different gutter systems. They can be easily installed and integrated with various types of gutter systems, ensuring effective drainage and protection against water damage.

- Q:Can FRP roofing panels be used in areas with heavy snowfall?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in areas with heavy snowfall. These panels are known for their durability and strength, making them suitable for withstanding heavy snow loads. However, it is important to ensure that the panels are installed and supported properly to handle the weight of the snow. Additionally, periodic maintenance and clearing of the panels may be required to prevent excessive snow accumulation.

- Q:Are FRP roofing panels suitable for buildings in coastal areas?

- FRP (Fiberglass Reinforced Plastic) roofing panels can be a suitable choice for buildings in coastal areas, but several factors should be considered. FRP panels are known for their durability, strength, and resistance to corrosion, making them suitable for environments where saltwater and high humidity are present. However, it is essential to choose high-quality FRP panels specifically designed for coastal areas. One of the main advantages of FRP roofing panels in coastal areas is their resistance to corrosion. Unlike traditional roofing materials like metal, which can easily rust in salty environments, FRP panels are resistant to saltwater, making them ideal for coastal buildings. Additionally, FRP panels have excellent UV resistance, which is crucial in areas with intense sun exposure. Another factor to consider is the wind load. Coastal areas are often exposed to strong winds and even hurricanes, so it is essential to select FRP panels that meet the necessary wind load requirements. Reinforced FRP panels with additional support structures may be necessary to ensure the panels can withstand high winds and protect the building adequately. Furthermore, it is important to consider the aesthetics of FRP roofing panels in coastal areas. While FRP panels are available in various colors and finishes, their appearance may not be suitable for all architectural styles or preferences. In such cases, alternative roofing materials that mimic the appearance of traditional materials may be a better choice. Lastly, regular maintenance is crucial for the longevity of FRP roofing panels in coastal areas. Despite their resistance to corrosion, salt and humidity can still cause gradual wear and tear. Regular cleaning and inspection are necessary to prevent any damage or degradation and ensure the panels continue to perform optimally. In conclusion, FRP roofing panels can be suitable for buildings in coastal areas due to their corrosion resistance, strength, and UV resistance. However, it is important to choose high-quality panels designed for coastal environments, consider wind load requirements, and perform regular maintenance to ensure their longevity and effectiveness.

- Q:Are FRP roofing panels resistant to chemical fumes?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to chemical fumes. FRP panels are known for their excellent chemical resistance properties, making them suitable for use in environments where exposure to chemical fumes is a concern. The chemical resistance of FRP roofing panels can vary depending on the specific type of resin used in their construction. However, in general, FRP panels are resistant to a wide range of chemicals, including acids, alkalis, solvents, and corrosive gases. It is important to note that while FRP panels offer chemical resistance, they may still be susceptible to damage or discoloration over time if continuously exposed to certain chemicals. Therefore, it is recommended to consult with the manufacturer or supplier of FRP roofing panels to ensure that they are suitable for specific chemical fume exposure conditions.

- Q:Can FRP roofing panels be used for skylights with opening mechanisms?

- Yes, FRP roofing panels can be used for skylights with opening mechanisms. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and provide excellent light transmission, making them a suitable material for skylights. They can be designed and manufactured with an integrated opening mechanism, allowing for ventilation and natural light control. The opening mechanisms can be operated manually or automatically, depending on the specific design and requirements. It is important to consult with a professional or manufacturer to ensure that the FRP roofing panels used for skylights with opening mechanisms meet the necessary safety and engineering standards.

- Q:Can FRP roofing panels be used for commercial kitchens?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for commercial kitchens. FRP panels are known for their durability, strength, and resistance to moisture, chemicals, and temperature fluctuations. These qualities make them an excellent choice for commercial kitchens, where there is often a high level of humidity, grease, and exposure to various chemicals and cleaning agents. FRP roofing panels are lightweight yet sturdy, making them easy to install and maintain. They are also fire-resistant, which is crucial in a kitchen environment where the risk of fire is higher due to the presence of cooking equipment. Additionally, FRP panels are easy to clean, as they have a non-porous surface that prevents the buildup of dirt, grease, and bacteria. Furthermore, FRP panels come in a variety of colors and finishes, allowing for customization to match the aesthetics of the commercial kitchen. They can also be installed in different configurations, such as skylights or translucent panels, to provide natural light while maintaining privacy. Overall, FRP roofing panels are a practical and reliable choice for commercial kitchens, providing a durable and hygienic solution that meets the specific requirements of this demanding environment.

- Q:Can FRP roofing panels be used for covered walkways in residential complexes or housing estates?

- Yes, FRP roofing panels can indeed be used for covered walkways in residential complexes or housing estates. FRP (Fiberglass Reinforced Plastic) roofing panels are a versatile and durable material that is commonly used in various construction applications, including walkway covers. One of the main advantages of using FRP roofing panels for covered walkways is their lightweight nature. Compared to traditional roofing materials like metal or concrete, FRP panels are significantly lighter, making them easier to install and transport. This is especially beneficial for residential complexes or housing estates where the construction process needs to be efficient and cost-effective. Additionally, FRP roofing panels are known for their excellent strength and durability. They are highly resistant to weather elements such as UV rays, moisture, and extreme temperatures. This means that they can withstand outdoor conditions over a long period without significant damage or degradation. For covered walkways in residential complexes, this durability ensures that the walkways remain safe and functional for residents, even during harsh weather conditions. Another advantage of FRP roofing panels is their versatility. They come in various sizes, colors, and textures, allowing for customization to match the architectural style and design of the residential complex or housing estate. They can also be easily shaped and molded to fit specific walkway configurations and requirements. In addition to their physical properties, FRP roofing panels are also known for their low maintenance requirements. Unlike other roofing materials, FRP panels do not corrode, rust, or require regular painting. This reduces the need for costly repairs and maintenance, making them a cost-effective choice for covered walkways in residential complexes. Overall, FRP roofing panels are a suitable and practical choice for covered walkways in residential complexes or housing estates. Their lightweight nature, durability, versatility, and low maintenance requirements make them an excellent option to ensure safe and aesthetically pleasing walkways for residents.

- Q:Can FRP roofing panels be used in food processing facilities?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in food processing facilities. FRP roofing panels are commonly used in various industrial applications, including food processing facilities, due to their excellent properties. FRP panels are corrosion-resistant, durable, lightweight, and can withstand harsh environmental conditions. In food processing facilities, where hygiene and cleanliness are of utmost importance, FRP roofing panels offer several advantages. They are non-porous and do not support the growth of bacteria or mold, making them easy to clean and maintain. Furthermore, FRP panels are resistant to chemicals and can withstand frequent washdowns with detergents and sanitizers without degradation. Additionally, FRP roofing panels can be easily installed, reducing downtime during construction or renovation projects. They are available in various thicknesses, colors, and profiles, allowing for customization to suit specific design requirements. Overall, FRP roofing panels are a suitable choice for food processing facilities, providing a hygienic and durable roofing solution that meets the stringent requirements of the industry.

- Q:Are FRP roofing panels resistant to chemical fumes or emissions?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to chemical fumes or emissions. FRP is known for its excellent corrosion resistance and can withstand exposure to a wide range of chemical substances without deteriorating or getting damaged. However, it is important to consider the specific chemicals involved and consult the manufacturer or a professional to ensure that the FRP roofing panels selected are suitable for the intended application and chemical environment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Manufacture Corrugated Metal Roof Sheet for Houses

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords