LOG-1080A8 Injection Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Quick Details | |

| Condition: New | Place of Origin: China (Mainland) |

| Type: Tube Head Injection | Plastic Type: Thermosetting |

| Style: Horizontal | Automatic: Yes |

| Brand Name: LOG | Injection Weight: 4540g |

| Model Number: LOG-1080A8 | Injection Rate: 21250px3/s |

| Opening Stroke: 1150mm | Clamping Force: 1080KN |

| Energy saving |

Packaging & Delivery

| Packaging Details: | the LOG-1080 will be shipped by 40'HP container,because of the weight and size |

|---|---|

| Delivery Detail: | 7 days after receive the diposit OR month |

Specifications

1.high response 2. high precise 3. oil saving 4. water saving 5. long warking life

Details

template structure of the high-rigidity design,with a bigger clamiping unit.

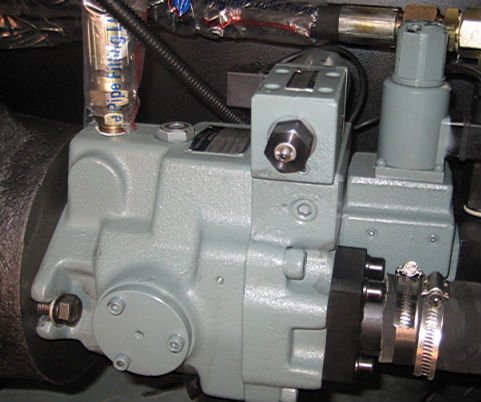

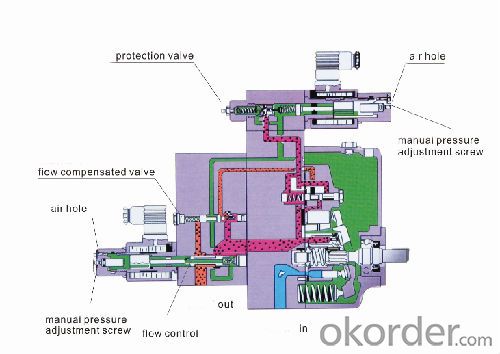

equipped with imported low-noise and high efficiency variable pump system,saving energy 30% to 60% and and 20 %~40% oil and water

high-efficiency filter makes the hydraulic oil clean and a long working life

the color screen control system, is conventional to operate it.

T- slots and conventional screw holes make mold is easy to install.

| LOG-1080A8 | |||||

| International size rating | 9080/1080 | ||||

| INJECTION | A | B | C | D | |

| Shot volume | cm3 | 4123 | 4989 | 5938 | 6968 |

| Shot weight | G | 3751 | 4540 | 5403 | 6340 |

| OZ | 132.8 | 160.8 | 191.4 | 224.5 | |

| Screw diameter | mm | 100 | 110 | 120 | 130 |

| Injection pressure | mpa | 220 | 182 | 153 | 130 |

| Screw L:D ration | 22:01 | 22:01 | 20:01 | 18.6:1 | |

| Screw stroke | mm | 525 | |||

| Screw speed(stepless) | r/min | 0-110 | |||

| CLAMPING UNIT | |||||

| Clamping force | kn | 10800 | |||

| Opening stroke | mm | 1150 | |||

| Platen size | mm×mm | 1650 X 1650 | |||

| Space between fie bars | mm×mm | 1150 X 1100 | |||

| Mold fhickness(Min-Max) | mm | 450-1200 | |||

| Max.daylingt | mm | 2350 | |||

| Hydraulic ejection stroke | mm | 350 | |||

| Hydraulic ejection force | kn | 270 | |||

| POWER UNIT | |||||

| Hydraulic system pressure | mpa | 17.5 | |||

| Pump motor | kw | 45+45 | |||

| Heating capacity | kw | 68.45 | |||

| Number of femp confrol zones | \ | 6+ nozzle | |||

| GENERRL | |||||

| Dry-cycle fime | Sec | 10 | |||

| Oil fank capacify | λ | 2300 | |||

| Machine dimensions | m×m×m | 12.5X2.8X3.5 | |||

| Machine weight | kg | 60000 | |||

Some details about the machine:

- Q:What kinds of oil are used in the injection molding machine?

- Look at it!. Spring and autumn days with 46# anti-wear hydraulic oil; but the general urban use 46# throughout the year to use, where you don't have much low temperature, in accordance with the standard conditions for winter 32# antiwear hydraulic oil, if there is a gear box to use gear oil.The main tank is mainly provided to meet the normal operation of the hydraulic system required flow, mainly with hydraulic oil, heat distribution,I contact the manufacturers are generally the Great Wall L-HM46#, anti-wear hydraulic oil consumption is relatively large. For hydraulic system lubrication and work, as well as other parts of the bearing grease, large tonnage models, which is related to the design of the oil circuit. Ask them how the hydraulic oil is used in the equipment. It is used for lubrication and work in the hydraulic system,

- Q:How to calculate the capacity of mold injection molding?

- For example, the first mock exam two points mold cycle for 15 seconds, then 12 hours of production capacity is 60 seconds /15 seconds = 4 mode 4X60=240 per minute per hour 240X12 hour = 2640

- Q:How many grams of 200t injection molding machine?

- Each injection molding machine is standard with three types of screw, mainly to see requirements, the smallest less than 200g, the largest more than 300, general ABS with medium-sized screw, PA, PC with small screw, PP with large screw.Energy conservation:The energy saving of injection molding machine can be divided into two parts: one is the power part, and the other is heating part.Energy saving: most of the power inverter, energy saving way is through energy saving more than the actual motor, such as motor power is 50Hz, and you actually need only in the production of 30Hz is sufficient to produce, the extra energy is wasted, the inverter is to change the output power of the motor to achieve the energy-saving effect.

- Q:How does the product mix?

- Friends note plastic flowers (silver or silver) of good hope to help?Silver good resolution?Production of raw materials: good drying. The heating barrel degassing Liang (water, gas, volatile, etc.), gas burning retention solutions, mould heating involved (including type changes are good flesh) shaped silver prototype surface show silver floating flow area not only limited traces of silver near the gate of primary and reflected out parts closely related, must understandTwo. Production: the so-called silver silver diagram shown in figure refers to the molten resin in bubbles, tensile effect of muscle strips flow marks because of the appearance of the silver bullion that look like muscle strips

- Q:How to adjust the injection molding machine, how to solve the shrinkage of injection molding products?

- The reasons for the machining parameters and the improvement measures are shown in the following table:1, keep the pressure too low, increase the dwell pressure2, the holding time is too short to extend the holding time3, die wall temperature is too high, reduce mold wall temperature4, melting material temperature is too high, reduce melting material temperature, reduce the barrel temperature

- Q:Can you tell me if there are 350 grams of three injection molding machines? How much? Thank you

- Well known low-end machines, cheap, should be around 9W.

- Q:List of injection molding machines

- Demag DEMAG Austria: Japan ENGEL brand: Toshiba TOSHIBA, Japan TOYO, MITSUBISHI MITSUBISHI, Sumitomo SEDU, FANUC FANUC method, Niigata NIIGATA,

- Q:For example, for nylon 6 GF30 material, some injection process information required to set the injection pressure is: 85-100MPa, the actual adjustment of the machine in our injection molding machine panel set the injection pressure is 65, then this number "65" unit is what?If the number of units is "bar", not with the data of some books conflict, please expert answer

- in fact, you can buy some books to look at the injection molding process, more contact with nature will be very clear.

- Q:How to repair the injection machine?

- Common faults in the use of injection molding machines and solutions are as follows:Part 1: Problems and treatment methods of mould locking parts:(1) not locking dies:Handling method: 1) check the front travel switch of safety door and repair it.2) check the 24V5A power in the electric box, replace the insurance and the power box.3): check whether the spool is stuck, cleaning the spool.4): check whether the output of the I/O board, the solenoid valve is charged.5): check whether the hydraulic safety switch is closed, whether the mechanical lock rod is opened or not.(two) the opening and closing of the die machine:Handling method: 1) check whether the lubricating oil pipe is broken or, if so, reconnect the tubing.2): small amount of lubricating oil, lubricating oil amount increase, 50 die once or manually add oil and lubricating oil.3): clamping force, check whether the mold needs large clamping force, lower the clamping force.4): the current fluctuation of the amplifier board, check whether the current parameters meet the acceptance criteria, re adjust the current value.5): parallelism error indicator check head board parallelism is greater than the acceptance criteria; adjust the parallelism.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LOG-1080A8 Injection Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords