Light Steel Frame Formwork with Plywood for Two Level Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 70000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

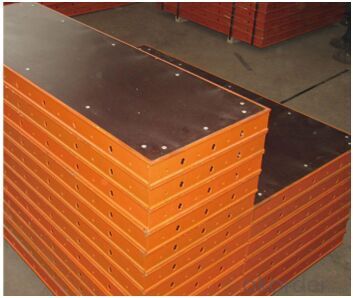

1. Structure of Light Steel Frame Formwork with plywood

Light steel frame formwork is constructed with two different plywood as frames-wood plywood and plastic plywood. The light frame formwork with plywood is quite weighing lightly and work faster.

2. Main Features of Structure of Light Steel Frame Formwork with plywood

Light with reasonably big sizes

Easily assemble with convenient use to reduce construction use and work load

Easy to get rid of concrete surface

More than 20 times repeated use

Warmth keeping for winter concrete use

Convenient for maintenance on site. One surface damaged , the other surface can be quickly replace.

Mainly used for vertical, horizontal and shear formwork in high building.

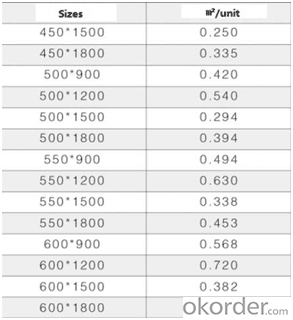

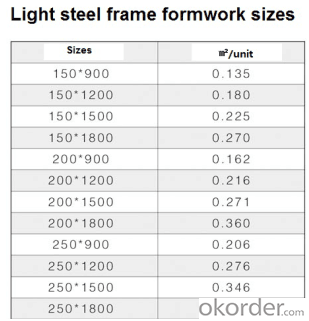

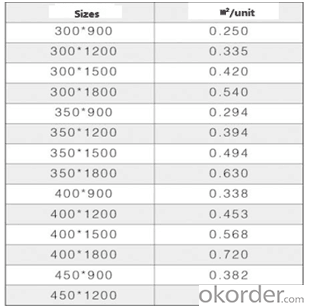

4. Light Steel Frame Formwork Specifications

5. FAQ of Light Steel Frame Formwork with plywood

1) What can we do for you?

.We can ensure the quality of the Light Steel Frame Formwork with Plywood and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:What are the different types of edge protection systems used with steel frame formwork?

- There are several types of edge protection systems commonly used with steel frame formwork. These include guardrails, toe boards, and safety nets. Guardrails are horizontal barriers that provide a physical barrier along the edges of the formwork to prevent falls. Toe boards are vertical barriers installed at the base of the formwork to prevent tools and materials from falling off the edges. Safety nets are installed below the formwork to catch any falling objects and prevent them from reaching the ground. These edge protection systems are essential for ensuring the safety of workers and preventing accidents on construction sites.

- Q:Can steel frame formwork be used for the construction of educational facilities?

- Yes, steel frame formwork can be used for the construction of educational facilities. Steel frame formwork is a versatile and durable system that provides a strong support structure for concrete during the construction process. Its strength and stability make it suitable for constructing various types of buildings, including educational facilities. One of the main advantages of steel frame formwork is its ability to withstand heavy loads and provide a safe working environment. This is particularly important for educational facilities, as they often accommodate a large number of people and require strong and durable structures to ensure the safety of students and staff. Additionally, steel frame formwork allows for flexibility in design and construction. It can be easily adjusted and customized to meet the specific requirements of educational facilities, such as the layout of classrooms, laboratories, and other specialized areas. This flexibility enables architects and engineers to create functional and efficient spaces that cater to the needs of students and educators. Furthermore, steel frame formwork is highly reusable and cost-effective. It can be dismantled and used multiple times for different construction projects, reducing waste and saving resources. This makes it an environmentally friendly choice for educational facilities, which often strive to promote sustainability and responsible construction practices. In conclusion, steel frame formwork is a suitable option for the construction of educational facilities due to its strength, stability, flexibility, and cost-effectiveness. Its ability to withstand heavy loads, provide a safe working environment, and be customized to meet specific requirements makes it an ideal choice for creating functional and efficient learning spaces.

- Q:How long does steel frame formwork last?

- The lifespan of steel frame formwork may vary depending on various factors, including the quality of the formwork material, appropriate maintenance, and the intensity of usage. Generally, steel frame formwork is renowned for its durability and long-lasting nature. Through adequate care and maintenance, it can endure for numerous years, often surpassing the lifespan of alternative formwork materials like timber or aluminum. Typically, steel frame formwork can be reused for multiple construction projects, presenting a cost-effective option for contractors. Nevertheless, it is crucial to regularly evaluate the condition of the formwork and replace any damaged or worn-out components to ensure safety and optimal performance.

- Q:What are the different types of accessories that can be used with steel frame formwork?

- Some common types of accessories that can be used with steel frame formwork include adjustable props, scaffolding systems, tie rods, formwork clamps, formwork panels, formwork corners, and various types of formwork anchors. These accessories help in providing stability, support, and alignment to the steel frame formwork system, ensuring efficient and safe construction processes.

- Q:Are there any specific design considerations when using steel frame formwork?

- When utilizing steel frame formwork in construction projects, there are various specific design considerations to be aware of. To begin with, it is essential to thoroughly assess and design the strength and stability of the steel frame formwork system. This is done to guarantee its ability to withstand the loads imposed during concrete pouring and curing. These loads encompass the weight of the concrete, wind loads, and any additional loads from construction equipment or workers. Furthermore, the dimensions and layout of the steel frame formwork must be designed in a manner that accommodates the desired shape and size of the concrete structure. This may involve integrating adjustable panels or modular components to allow for flexibility and ease of assembly. In addition, the connections between the steel frame formwork components necessitate careful design to ensure proper alignment and stability. This may entail utilizing high-quality fasteners and ensuring that the connections are adequately braced to prevent any movement or deformation during the concrete pouring process. Moreover, it is important to consider the surface finish requirements of the concrete structure. Steel frame formwork can leave imprints or marks on the concrete surface, so appropriate measures should be taken to minimize any undesirable effects. This can be achieved by employing plywood or plastic lining on the contact surfaces. Lastly, safety should be a paramount consideration when employing steel frame formwork. The design must incorporate suitable safety features, such as guardrails, handrails, and access platforms, to ensure the well-being of workers during the construction process. Overall, a successful and efficient construction process using steel frame formwork necessitates the consideration of structural strength, dimensional requirements, connections, surface finish, and safety.

- Q:How does steel frame formwork accommodate for expansion and contraction of concrete?

- The design and construction of steel frame formwork take into account the expansion and contraction of concrete. Expansion joints are incorporated into the structure by creating gaps in the formwork, enabling the concrete to expand and contract without causing harm to the overall structure. Moreover, adjustable connections are utilized in the construction of steel frame formwork, allowing for slight movement and shifting as the concrete expands or contracts. These connections can be adjusted as necessary to accommodate any changes in the dimensions of the concrete. Furthermore, steel has a higher coefficient of thermal expansion compared to other materials. This characteristic of steel helps to absorb the expansion and contraction stresses that the concrete may undergo. The steel frame formwork acts as a buffer, absorbing and distributing these stresses to prevent cracking or distortion in the concrete. In conclusion, steel frame formwork is designed to offer flexibility and adaptability to the concrete structure, ensuring its long-term durability and stability while allowing for expansion and contraction.

- Q:How does steel frame formwork compare to traditional timber formwork?

- Steel frame formwork is a modern and efficient alternative to traditional timber formwork, making it a preferred choice in many construction projects due to several advantages it offers. Superior strength and durability are provided by steel frame formwork. Unlike timber formwork, which is susceptible to warping, shrinking, and swelling due to moisture, steel frame formwork remains stable and unaffected by weather conditions. As a result, a consistent and accurate formwork system is ensured, resisting deformation and resulting in a higher quality finished product. Another advantage is the versatility of steel frame formwork, which can be easily customized to suit different project requirements. It allows for easy adjustments and modifications, making it suitable for complex geometries and unique architectural designs. In contrast, timber formwork is limited in flexibility and requires more effort and time to adapt to various shapes and sizes. Steel frame formwork is also advantageous in terms of reusability. Unlike timber formwork, which has a limited lifespan before replacement, steel frame formwork can be reused for multiple projects. This not only reduces material waste but also offers long-term cost savings. Improved safety on construction sites is another significant advantage of steel frame formwork. Its rigid structure and secure connections provide better stability, reducing the risk of accidents and injuries. Additionally, steel formwork allows for easier access and maneuverability, enabling workers to carry out their tasks more efficiently and safely. Steel frame formwork also contributes to faster construction timelines. The simple and efficient assembly and disassembly process of steel formwork result in shorter construction cycles. This allows for increased productivity and reduced labor costs compared to traditional timber formwork, which requires more time and effort to set up and dismantle. Overall, steel frame formwork surpasses traditional timber formwork in terms of strength, durability, versatility, reusability, safety, and construction speed. Its numerous advantages make it a preferred choice for construction projects, saving both time and costs while ensuring high-quality results.

- Q:What are the cost implications of using steel frame formwork?

- The cost implications of using steel frame formwork can vary depending on several factors. Steel frame formwork is generally more expensive upfront compared to traditional timber formwork. However, it offers several advantages such as durability, reusability, and faster construction speed, which can offset the initial higher cost. Additionally, steel formwork requires less maintenance and has a longer lifespan, reducing overall costs in the long run. It also provides better structural integrity and accuracy, resulting in potential savings in material and labor costs. Ultimately, the cost implications of using steel frame formwork should be evaluated based on the specific project requirements, timeline, and budget.

- Q:How does steel frame formwork handle the pouring and curing of concrete in multiple stages?

- Steel frame formwork is a highly versatile and efficient system that is specifically designed to handle the pouring and curing of concrete in multiple stages. This formwork system consists of sturdy steel frames that are assembled to create a temporary mold or framework for the concrete to be poured into. During the pouring stage, the steel frame formwork is carefully positioned and secured in place to ensure stability and accuracy. The frames are typically adjustable, allowing for flexibility in accommodating different shapes and sizes of concrete structures. Additionally, the formwork may have built-in features such as adjustable form ties or clamps to hold the formwork together tightly during the pouring process. Once the concrete is poured into the steel frame formwork, it is left to cure and harden. The steel frames provide excellent support and stability, preventing any deformation or movement of the concrete during the curing stage. This is crucial to ensure the structural integrity of the final concrete structure. In cases where the pouring and curing of concrete need to be done in multiple stages, steel frame formwork offers great convenience and efficiency. The formwork can be easily disassembled and repositioned to accommodate the next stage of pouring. This allows for a seamless transition between different sections or levels of the construction project. Moreover, steel frame formwork can be quickly and easily cleaned and prepared for the next stage of pouring. Its reusable nature significantly reduces material waste and cost, making it a sustainable and economical choice for construction projects. In summary, steel frame formwork is specifically designed to handle the pouring and curing of concrete in multiple stages. It provides stability, accuracy, and flexibility during the pouring stage, and ensures the structural integrity of the concrete during the curing stage. Its versatility and reusability make it a preferred choice for construction projects requiring efficient and reliable formwork systems.

- Q:How does steel frame formwork prevent concrete shrinkage or cracking?

- Steel frame formwork is an effective solution to prevent concrete shrinkage or cracking due to its robust and rigid structure. The steel frames act as a support system that holds the concrete in place during the curing process. This prevents the concrete from moving or shifting, allowing it to dry evenly and reducing the risk of shrinkage or cracking. One of the main advantages of using steel frame formwork is its ability to provide excellent reinforcement and stability to the concrete structure. The steel frames are designed with precise measurements and are securely fixed in place, ensuring that the concrete retains its shape and form while it cures. This eliminates any potential for uneven drying or settlement, which can lead to shrinkage or cracking. Additionally, steel is known for its high tensile strength and durability, making it an ideal material for formwork. The steel frames can withstand the pressure exerted by the wet concrete and prevent it from expanding or contracting excessively as it dries. This stability minimizes the development of internal stresses within the concrete, which are a common cause of shrinkage or cracking. Furthermore, steel frame formwork provides a smooth and seamless surface for the concrete. This prevents the formation of voids or air pockets, which can weaken the concrete structure and increase the likelihood of shrinkage or cracking. The tight fit between the steel frames ensures that the concrete is uniformly distributed and compacted, resulting in a stronger and more resilient finished product. Overall, steel frame formwork plays a crucial role in preventing concrete shrinkage or cracking by providing a stable and supportive structure during the curing process. Its robustness, precise measurements, and ability to withstand pressure ensure that the concrete retains its shape and dries evenly. By eliminating uneven drying, settlement, and internal stresses, steel frame formwork helps to create a high-quality, durable, and crack-free concrete structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Steel Frame Formwork with Plywood for Two Level Building

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 70000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords