Iron Check Valve DN80 High Quality Hot sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sizes: DN100 - DN800

Pressure: 1.6 - 6.4MPa

Suitable temperature: <80 C

Connection: RF

Constant Head Check Valve

Sizes: 4“ - 48"

Pressure: 1.6 - 6.4MPa

Suitable temperature: <80°C

Connection: RF

| aterial list(CN standard): | |||||

| NO. | Part Name | Carbon Steel Series | Stainless Steel Series | Alloy Steel Series | Low-temperature Steel Series |

| 1 | Body | WCB | CF8 | WC6 | LCB |

| 2 | DISC | WCB | CF8 | WC6 | LCB |

| 3 | Washer | Flexible graphite+ss304 | Flexible graphite+ss304 | Flexible graphite+ss304 | Flexible graphite+ss304 |

| 4 | Bonnet | WCB | CF8 | WC6 | LCB |

| 5 | Studs | 35CrMoA | 0Cr18Ni9(304) | 35CrMoA | 0Cr18Ni9(304) |

| 6 | Nut | 35# | 0Cr18Ni9(304) | 35CrMoA | 0Cr18Ni9(304) |

| 7 | Spring | 60Si2Mn | 0Cr18Ni9(304) | 0Cr18Ni9(304) | 0Cr18Ni9(304) |

| Technical Specification: | |||||||

| Design Standard | GB/T 12235 | ||||||

| Temperature Pressure Rating | GB/T 12224 | ||||||

| Structural Length | Factory Standard | ||||||

| Flange Dimensions | GB/T 9113,GB/T 79 | ||||||

| Inspection and Test | JB/T 9092,GB/T 13927 | ||||||

| nominal pressure | PN1.6 | PN2.5 | PN4.0 | PN6.4 | PN10.0 | PN16.0 | |

| Test Pressure(Mpa) | Body Test | 2.4 | 3.75 | 6.0 | 9.6 | 15.0 | 24.0 |

| High Pressure Seal | 1.76 | 2.75 | 4.4 | 7.04 | 11.0 | 17.6 | |

| Low Pressure Seal | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | |

| Applicable temperature | -196°C~550°C(Differeent temperature use different material) | ||||||

| Applicable Medium | water,gas,oil and corrosive media(different media use different material) | ||||||

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

| Power: | Hydraulic | Material: | Carbon Steel, Stainless Steel | Temperature of Media: | Medium Temperature |

| Media: | Water, Oil, Gas etc. | Port Size: | DN250 | Place of Origin: | Hebei, China (Mainland) |

| Model Number: | OEM | Brand Name: | cmax | Application: | General |

| Name: | Check Valve | Type: | Lift Check Valve | Nominal Diameter: | DN15~900,NPS 1/4 ~36 |

| Nominal Pressure: | PN1.0-16.0MPa,ANSI CLASS 150-900,JIS10-20K | Connection Type: | Flange, butt welding, thread, socket welding, the clamp, etc | Working Temperature: | -196℃~540℃ |

| Valve Body Material: | WCB,CF8(304),CF3(304L),CF8M(316),CF3M(316L), | Applicable Medium: | Water, Oil, Gas etc | Model: | OEM |

| Certificate: | ISO9001, ISO4001 |

Application

Petroleum, chemical industry, pharmacy, fertilizer, power industry etc.

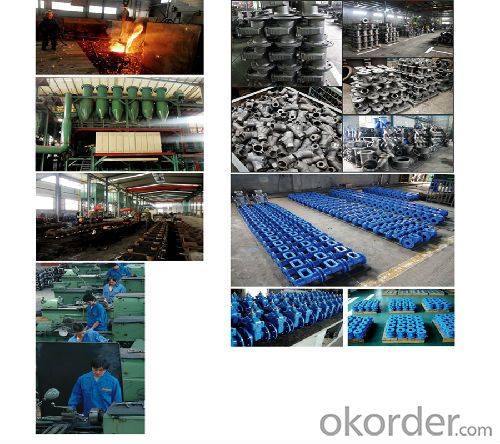

Advantage

1.Lift check valve is self-sealing valve. The disc can be acted by the flow which can protect against the media flow back.

2.The disc with spring can keep the valve work in any direction.

3.Reasonable structure, reliable sealing, excellent performance and attractive appearance make a TKFM valve.

- Q:Check valve symbols?

- The check valve is divided into three kinds: lift check valve, swing check valve and butterfly check valve:1. lift check valve is divided into two types of vertical and horizontal.2. swing check valve is divided into single, double flap and multi flap type of three.3. butterfly check valve is straight through type.The above types of check valves can be classified into thread connection, flange connection, welding connection and clamp connection in connection forms of four kinds.

- Q:Check valve note BC/PISTON: SPR-L what does that mean?

- BC==Bolted Cover/ bolted bonnetPISTON== lifting typeSPR-L==Spring-loaded/ is loaded with springsTogether, it is: a spring-loaded check valve. Bolted bonnet (this is common)

- Q:Tap water tank with vertical and horizontal check valve.

- Extrusion includes seat and plate or piston designed to prevent the valve slamming. Additional material added to the seat produces two extrusion zones. Try to squeeze the fluid out of these areas and slow down the valve during rapid closing. But there is a price to pay for that. The limited gap increase region is an ideal site for collecting small solid particles. The squeeze pressure protection for controlled closure, due to the collection of solids, may cause additional problems, unless the gap is sufficiently extruded, the solids can be ejected. A narrow seal may shatter a fragile solid, such as coal. The extrusion zone tends to expand the width of the available valve seat and reduce the ability of the valve to crush solids. This effect must be considered, taking into account all the characteristics of the related solids.

- Q:Check valve 1 inches DN25 what do you mean?

- Crown valve pressFirst, an inch equals DN25That is, fixed values to estimate how large a pipeline isOne inch of check valve is mostly copper check valveThe price of I should be around 25 yuan

- Q:What's the difference between a throttle valve and a check valve? Are they the same?

- The principle is very simple, just like upstairs said, like a revolving door, this is the swing test. There are lifting type, it is unknown.And "throttling" is to reduce the pressure of the fluid. In the pipeline, the fluid through the throttle valve, through the hand wheel or other transmission way to adjust the size of the internal channel, so that the flow of fluid flow down, to save traffic flow.

- Q:I use water pump pumping 78 meters deep underground water, the pipe is 2.5 inches large, with ordinary check valve, water is always sucked back, I would like to ask what method or what kind of check valve to be selected (check valve to be installed on the side of the pump)

- The ideal way is to set up a vacuum tank so that it doesn't return all the time without irrigation each time. Check valve because of different quality, more or less water leakage, stop time will be long after the leak.

- Q:Install check valve is not afraid of water, in case the back of the water pollution?

- The function of the check valve is to prevent water from flowing back. It is mainly used at the pump outlet to protect the water pump. Of course, it is also possible to prevent backwater pollution. Where to use it, mainly to function, is not necessarily to be applied in a traditional way!

- Q:How do I install the pump outlet check valve?

- Installation of pump outlet check valves: swing check valves are generally mounted on horizontal pipes: for DN~80mm check valves, they can also be mounted on vertical or upward sloping pipes. The straight through lift check valve shall be installed on the horizontal pipe; the vertical lift check valve must be installed on the vertical pipe, and the medium shall be from bottom to top.

- Q:Are check and check valves the same kind of thing?

- Yes, that's right. Ha-ha。 My friend needs an anti - stop valve to find me. I have one for sale here.

- Q:What kind of valve does the check valve belong to?

- 1. check valves are automatic valves;2., if the valve is cast iron, can be cast iron valves; if the valve is cast steel, can be cast steel valves; of course, can also beIn copper valves, stainless steel valves,,,,,,,3., if used in steam, can belong to the steam valve

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Iron Check Valve DN80 High Quality Hot sell

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords