Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve

Design Feature Of Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve:

The products feature a reasonable structure, reliable seal, good performance and nice modeling.

Either soft or hard seal can be selected for the product upon different working conditions. The sealing face is built up with Co-based carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

Small opening pressure, the disc can be opened fully with a very small pressure differential.

Inside-set bolt-bearing structure reduces leakage and reliable use.

Class≥1500LB, the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along with the pressure rise so as to ensure the sealing performance.

Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirement.

Specifications Of Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve:

Class 150~1500, NPS 1/2~36"

Basic Design: ANSI B16.34, BS 1868

Face to Face Dimension: ANSI B16.10

Flanged Ends: 2~24" to ANSI B 16.5, >24" to MSS SP-44, to API 605 on request

B. W. Ends to ANSI B 16.25

Manufacturing to NACE MR-01-75 on request

Dimensions:

Size(DN) | L | D | D1 | D2 | b | n-d | H | W.T(kg) |

40 | 180 | 150 | 110 | 84 | 18 | 4-19 | 110 | 9 |

50 | 200 | 165 | 125 | 99 | 20 | 4-19 | 130 | 13.4 |

65 | 240 | 185 | 145 | 118 | 20 | 4-19 | 140 | 17.7 |

80 | 260 | 200 | 160 | 132 | 22 | 8-19 | 150 | 20.8 |

100 | 300 | 220 | 180 | 156 | 24 | 8-19 | 160 | 29.3 |

125 | 350 | 250 | 210 | 184 | 26 | 8-19 | 190 | 47 |

150 | 400 | 285 | 240 | 211 | 26 | 8-23 | 210 | 67 |

200 | 500 | 340 | 295 | 266 | 30 | 12-23 | 250 | 118.7 |

250 | 600 | 405 | 355 | 319 | 32 | 12-28 | 310 | 171.9 |

300 | 700 | 460 | 410 | 370 | 32 | 12-28 | 340 | 232.5 |

350 | 800 | 520 | 470 | 429 | 36 | 16-28 | 450 | 330 |

400 | 900 | 580 | 525 | 480 | 38 | 16-31 | 520 | 460 |

450 | 100 | 640 | 585 | 548 | 40 | 20-31 | 550 | 580 |

500 | 1100 | 715 | 650 | 609 | 42 | 20-34 | 590 | 700 |

600 | 1300 | 840 | 770 | 720 | 48 | 20-37 | 680 | 780 |

Trim Material to API 600

Seating | Seat Ring | Disc Seat | Hinge Pin Part NO. 13 |

1 | 13Cr | 13Cr | F6 |

2 | 304 | 304 | F304 |

5 | Stellite | Stellite | F6 |

8 | Stellite | 13Cr | F6 |

9 | Monel | Monel | Monel |

10 | 316 | 316 | F316 |

13 | Alloy20 | Alloy20 | Alloy20 |

Test Pressure to API 598

Class | Body Material | Shell Test (Hydrostatic) | Seat Test (Hydrostatic) | Seat Test (Air) |

150 | WCB | 450psi | 315psi | 80psi |

WC6 | 450psi | 319psi | ||

CF8M | 425psi | 303psi | ||

300 | WCB | 1125psi | 814psi | |

WC6 | 1125psi | 825psi | ||

CF8M | 1100psi | 792psi | ||

600 | WCB | 2225psi | 1628psi | |

WC6 | 2250psi | 1650psi | ||

CF8M | 2175psi | 1548psi | ||

900 | WCB | 3350psi | 2442psi | |

WC6 | 3375psi | 2475psi | ||

CF8M | 3250psi | 2376psi | ||

1500 | WCB | 5575psi | 4078psi | |

WC6 | 5625psi | 4125psi | ||

CF8M | 5400psi | 3960psi |

Usage/Applications Of Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve:

Check Valves are used in pipes under pressure between Class 150~2500LB, working temperatures﹣196~600℃. They are used in industries including oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

Tests Of Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve:

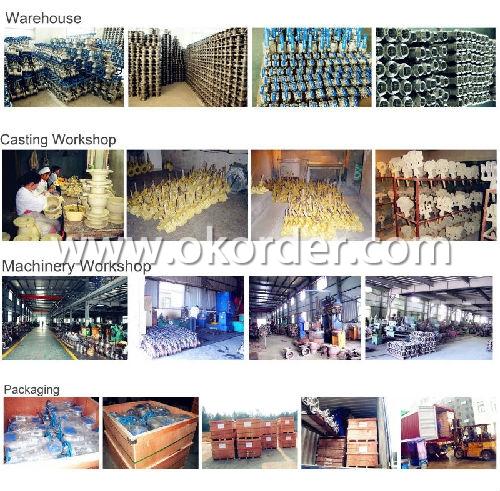

Packaging & Delivery Of Forged Steel Piston ANSI Swing Flanged Check Valve: Packaging: Inner packing: Plastic bags, Outer packing: Cartons and wooden case. Delivery: By Sea in 20ft and 40ft containers We can supply high quality of Forged Steel Piston ANSI Swing Flanged Check Valve with best price and fast delivery.

- Q:Are the gate valves and check valves of the same type?

- It is a kind of valve opening and closing function (i.e. switch) of the valve, it is on the gate lifting and play the role of the switch, the switch is to be applied by external force (hand wheel, electric, pneumatic and hydraulic) it is not required to;Check valve is a check valve function, is to prevent the media back, it is by the valve on the pin shaft and the rotary switch to play the role of the valve with different things, when it is opened by medium pressure automatic opening, closing time depending on the medium and back type the self gravity valve closed, it is a kind of automatic gate valve function, does not require an external force is applied to it, it is a demand for the direction.

- Q:How to install industrial check valves? How should they be used?

- 4, the check valve closes, will produce water hammer in pipeline pressure, will lead to serious damage to the valve and piping or equipment, especially for the big pipe or high pressure pipeline, it should pay attention to those who use check valve. (end)Check valve to have two kinds, one is installed in the pump before the vertical Straw end, the purpose is to take out a water pump to charge a water pump and pump, because Straw in the anhydrous pump only idle pumping Sheung Shui, so the pump must be filled with water to produce water. The installation of this pump is a kind of method is higher than the water level when the negative pressure is also called method such as drawing water from wells. Another method is the liquid level above the pump pump installation, for this method of using two water supply, because the liquid level above the pump to start and stop the pump when convenient do not turn off the pump outlet valve, the check valve should be installed in the pump in the rear.

- Q:Is it better to have explicit rules in the relevant specifications? Thank you, ah, ah, urgent.

- Article 8.5 of the code for fire protection design of high-rise civil buildings provides as follows:8.5.3 one of the following circumstances shall be equipped with fire dampers for the ventilation and air conditioning systems:8.5.3.1 pipe through fire compartment.

- Q:Check valve does not automatically check back, how to adjust?

- 4 the vertical lift check valve shall be mounted on a vertical pipe.5, the lift type horizontal check valve shall be installed on the horizontal pipe.6. Do not check the weight of the valve in the line. The large check valve shall be independently supported so as not to be affected by the pressure caused by the piping system.

- Q:Check valve h42h-dn80 what does that mean?

- According to the provisions of the JB/T 308-2004 valve type programming method:H = check valve4 = connection: flange2 = structure form: vertical lifting typeH = sealing surface material: Cr13 stainless steelDN80== nominal diameter: 80mm

- Q:What's the difference between the h76x check valve h77x?

- Check JB/T308-2004 "valve type programming method"The first number 7 is the clip typeThe 6 is a double valve swing structure7 butterfly check valveLook at the JB/T8937-2010 "clip on check valve"That's clear

- Q:Installation of stainless steel tank outlet must be equipped with check valve?

- A stainless steel ball valve can also ah, inner thread

- Q:Fire hood fire check valve okay?

- Lampblack machine flue check valve is generally installed in the hood outlet check valve, the valve has two blades, a reset spring, exhaust hood leaf was blown open, lampblack machine stop when the blade is spring pressed into the closed state, now is basically take lampblack machine the check valve check valve, but the general tightness is not very good, open the hood can be seen around the gap.

- Q:What is the air pipe check valve?

- One-way valve, one-way flow, to prevent negative pressure reflux.

- Q:Install check valve is not afraid of water, in case the back of the water pollution?

- The function of the check valve is to prevent water from flowing back. It is mainly used at the pump outlet to protect the water pump. Of course, it is also possible to prevent backwater pollution. Where to use it, mainly to function, is not necessarily to be applied in a traditional way!

1. Manufacturer Overview |

|

|---|---|

| Location | Beijing,China |

| Year Established | 1986 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, Asia, America, Europe, Middle East, West Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Beijing |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 498 People |

| Language Spoken: | English,Chinese |

| b)Factory Information | |

| Factory Size: | 42000 square meters |

| No. of Production Lines | Above 20 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Sells Forged Steel Piston ANSI Swing Flanged Check Valve

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords