CHECK VALVE SWING TYPE SINGLE DISC DUCTILE IRON DN50- DN400

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Medium Pressure |

Power: | Hydraulic | Material: | Casting | Temperature of Media: | Medium Temperature |

Media: | Water | Port Size: | DN50-400 | Place of Origin: | China (Mainland) |

Model Number: | H76X | Brand Name: | CMAX | Application: | General |

Name: | Single disc wafer type check valve | Standard: | API,DIN,JIS,BS, | Medium: | wafer,oil,gas,Acid,alkali |

Valve body material: | cast iron,Stainless steel,brass | Size: | 2"~16" or DN50~DN400 | Advantage: | no leakage |

Packaging & Delivery

Packaging Details: | Veneer board boxes |

Name:Wafer type check valve,single door check valve,wafer type swing check valve.

Valve body:cast iron ,GG25,GGG40,CF8M

1.Working pressure:1.6Mpa

2.Testing :API598 DIN3230

3.Flange standard

DIN2501 PN10/16

BS4504 PN10/16

BS10 TABLE "D"/"E"

JIS2220 10K/16K

ANSI125/150

4.Face to face

ANSI125/150

DIN3203 K3-1999

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

- Q:What is the reason that the check valve does not stop water?

- 7, when installing check valve, should pay special attention to medium flow direction, should make medium normal flow direction and the direction of the arrow on the valve body is consistent, otherwise it will cut off the normal flow of media. Valve should be installed at the bottom of the pump suction pipe.The general formula 8, lift check valve should be installed in horizontal pipe, vertical lift check valve and bottom valve is usually installed in a vertical pipe on the road, and the bottom-up flow of media.9, the check valve closes, will produce water hammer in pipeline pressure, will lead to serious damage to the valve and piping or equipment, especially for the big pipe or high pressure pipeline, it should pay attention to those who use check valve.

- Q:Check valve note BC/PISTON: SPR-L what does that mean?

- BC==Bolted Cover/ bolted bonnetPISTON== lifting typeSPR-L==Spring-loaded/ is loaded with springsTogether, it is: a spring-loaded check valve. Bolted bonnet (this is common)

- Q:Is it necessary to install a check valve in the piston refrigeration compressor?

- To solve this problem, we first need to know the working cycle of the piston compressor:1, compression process, suction valve closed, refrigerant gas in the cylinder from low pressure to high pressure process;2 the exhaust process, compression end, from the cylinder through the exhaust valve to exhaust pipe process;3, expansion process, exhaust end, exhaust valve closed, the piston from the bottom of the cylinder moving to the top of the cylinder process;4 suction process, suction valve opens, low-pressure refrigerant gas inhalation process of the cylinder;From the above piston engines don't seem to need what steps to open check valve. Because the suction valve and exhaust valve on the cylinder are constantly switching each other, the piston machine continues to inhale and exhaust the process. If only from the piston machine, there is no need to install a check valve.But to consider the whole refrigeration system, rather than a simple piston compressor, when the piston of more than 2 units must be horizontal pipeline in a single compressor exhaust pipe to the exhaust duct installed on the check valve and pipe installation is about

- Q:Is the tank stop valve a non-return valve or a check valve?

- Check valve is a one-way valve, automatically prevent reverse flow of fluid, no knob, can not be artificial blocking forward flow.

- Q:Can the flue check valve and kitchen check valve protect against odor?

- Not really. It depends on what valve it is. If it is a variable pressure air valve, of course, if it is an ordinary other valves, generally only temporary role. Five residential home kitchen platoon smoke system is the application of this variable pressure air valve.

- Q:Only one is a soft seal and one is hard sealed

- Swing check valve is a check valve, the structure of the valve for the rotation of the axis of the general term, rubber valve check valve is people's usual name for H44X, only a swing check valve

- Q:Installation of stainless steel tank outlet must be equipped with check valve?

- A stainless steel ball valve can also ah, inner thread

- Q:What does the check valve "H64" and "H14" mean?

- H check valve6 welding connection1 threaded connection4 swing check valveJB/T308-2004< valve type programming method >There should also be sealing surface material code and nominal pressure level

- Q:Should the flue check valve be made by the civil team or the installation team?

- The kitchen flue and check valve are all constructed by civil engineering.

- Q:What are the differences between different check valves applications? For example, is the fire pump outlet swing check valve or a silent check valve? According to 35How to recognize single wall corrugated pipe and double wall corrugated pipe? Which is better?.What's the use of the silent check valve? And the bellow problem below, is there no answer?

- The application performance of the acoustic check valve only allows the medium to flow in one direction, and prevents flow in the direction. Usually the valve is automatically work, fluid pressure flow in one direction, the valve open; the opposite direction of fluid flow by gravity, fluid pressure and valve closing effect on the valve seat, thereby cutting off flow. Not suitable for medium containing solid particles and viscosity. The design of the check valve takes full account of the requirements of the use of the environment, and uses the inclined plate structure to achieve no vibration, no noise, stable operation, and ensure the quiet environment of the hotel and the residential environment, and has the effect of energy saving.

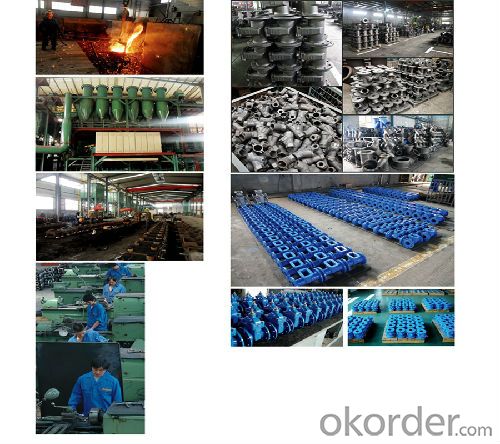

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CHECK VALVE SWING TYPE SINGLE DISC DUCTILE IRON DN50- DN400

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords