Injection molding machine LOG-400S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG 400S8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 1646

Clamping Force: 4000kn

Opening Stroke: 710mm

Power(W): 37kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

|---|---|

| Delivery Detail: | 30 Days |

Product performance and advantages:

Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-400S8 Technical parameters

Description | Unit | LOG-400S8 | ||

international recognized models | 2860/400 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 1385 | 1810 | 2290 |

Shot volume | g | 1260 | 1646 | 2084 |

Oz | 44.1 | 57.5 | 73.8 | |

Screw diameter | mm | 70 | 80 | 90 |

Injection diameter | mpa | 206 | 158 | 125 |

Screw L:D ratio | 24:1 | 21:1 | 19:1 | |

Scerw steoke | mm | 360 | ||

Screw rotate speed | r/min | 0-135 | ||

CLAMPING UNIT | ||||

Clamping force | kN | 4000 | ||

Opening stroke | mm | 710 | ||

Platen size | mm*mm | 1060*1040 | ||

Space between tie bars | mm*mm | 730*710 | ||

Maldthickness | mm | 250-730 | ||

Platen Mix stroke | mm | 1400 | ||

Ejection stroke | mm | 185 | ||

Ejcetion force | kN | 111 | ||

Power/Elcetric Heating | ||||

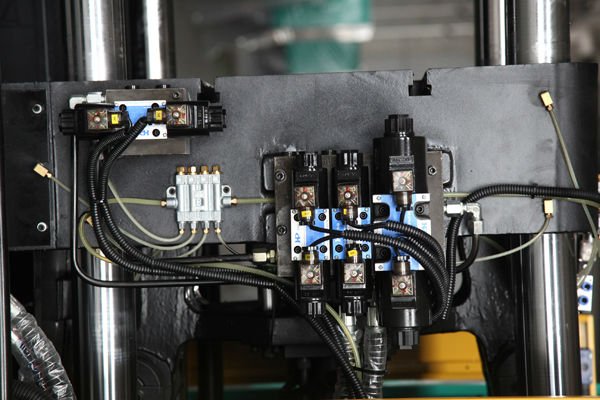

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 37 | ||

Heating power | kw | 35.85 | ||

Number of temp.conteol | 5+nozzle | |||

Other | ||||

Cycle time | sec | 5.1 | ||

Tank volume | L | 820 | ||

Machine dimesions | m*m*m | 8.6*1.75*2.35 | ||

Weight of machine | kg | 17000 | ||

Hydraulic presses have historically been the only option available to molders until Nissei Plastic Industrial Co., LTD introduced the first all-electric injection molding machine in 1983.

Hydraulic machines, although not nearly as precise, are the predominant type in most of the world, with the exception of Japan.Injection molding machines can fasten the molds in either a horizontal or vertical position. The majority of machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. Some vertical machines also don't require the mold to be fastened. There are many ways to fasten the tools to the platens, the most common being manual clamps (both halves are bolted to the platens); however hydraulic clamps (chocks are used to hold the tool in place) and magnetic clamps are also used. The magnetic and hydraulic clamps are used where fast tool changes are required.

- Q:How will the clamping force and injection pressure of injection mould be set?

- The clamping force is usually formulated according to the projection area of the product, and there is an estimate of the clamping force in the die design to select the model of the injection machine. Injection pressure is generally obtained from the die flow analysis, but the flow analysis is not very accurate. In general, the injection pressure of PP products is 50-70, and the injection molding is a little higher (plastic with poor flowability, such as POM, PA, etc.). Injection pressure is based on actual production experience

- Q:How many moulds can the 80 ton injection molding machine put down?

- There are two main decisions: meaning opening distance, and two is the distance between the guide pillars.

- Q:Automation has to be done at the present time when labor costs are going up sharply,

- At present, there are many kinds of injection molding machines on the market, and it is a very realistic problem how to select the suitable manipulator in so many kinds of mechanical hand. For the factory technicians who want to apply the manipulator, the manipulator needs to choose from the following aspects: first of all, the understanding of the tonnage of the existing injection molding machine. Different tonnage injection molding machine corresponds to the template size and height of the safety door of different sizes, the template size directly determines the mechanical hand travel, safety door height affects the product from the mold to the mold is smooth out, the two key dimensions determined to consider how the payload of the manipulator is not enough, the weight of injection molding products.

- Q:What is low voltage protection (injection molding machine)?

- That is, the injection molding machine in the mold process, there is a low pressure molding process, we will set a number, if the mold process to reach this pressure, there will be a low pressure alarm signal!In popular terms, the low pressure is only an exploratory fit! Do you understand this? When you have problems, think more; there is always answers!!

- Q:Injection molding machine outjected products should be red, why will change

- Reasons: 1., the cylinder is not clean, 2. molding temperature is too high, 3. toner is not resistant to temperature, or raw material forming temperature and toner temperature inconsistent. I hope I can help you......

- Q:How many grams of 200t injection molding machine?

- Each injection molding machine is standard with three types of screw, mainly to see requirements, the smallest less than 200g, the largest more than 300, general ABS with medium-sized screw, PA, PC with small screw, PP with large screw.Energy conservation:The energy saving of injection molding machine can be divided into two parts: one is the power part, and the other is heating part.Energy saving: most of the power inverter, energy saving way is through energy saving more than the actual motor, such as motor power is 50Hz, and you actually need only in the production of 30Hz is sufficient to produce, the extra energy is wasted, the inverter is to change the output power of the motor to achieve the energy-saving effect.

- Q:What should be noticed before the machine is stopped when the injection machine is finished?

- 1, stop feeding (feed off the front barrel, the barrel bottom) has been playing in the finished material2 shut down mold cooling water before stopping,3, press the manual (if not change the mold, stop the mold to the low pressure position, protect the mold)4, mold spray rust inhibitor5, turn off the electric heat6, turn off the power7, cleaning machine sanitation

- Q:Injection molding machine products shrink, how to solve?

- Injection pressure, holding pressure, speed, back pressure, temperature, glue content, inlet and die temperature

- Q:How can the injection machine be set with parameters?

- Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.Operation points:Before booting1. before the injection machine operation, check the electrical control box whether there is water, oil enter, if the electric equipment is wet, don't turn on the machine. The maintenance personnel should dry the electrical parts and then turn on the machine.2. before the injection machine operation, check whether the supply voltage is consistent, generally should not exceed 6%.3. check emergency stop switch, front and rear safety door switch is normal. Verify whether the motor and the pump rotate in the same direction.

- Q:What is the problem of Shanghai plastic injection molding machine in the die closing process?

- Solenoid valve installed wrong, or out of the oil path is simple along the road, and the solenoid valve is connected to reverse.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection molding machine LOG-400S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords