Injection Molding Machine LOG-160A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A8 CONFIGURATIONS

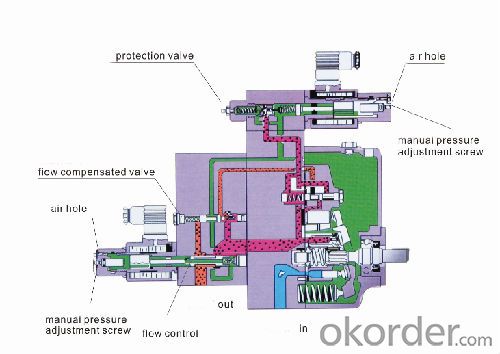

PROPORTIONAL VARIABLE PUMP YUKEN

OIL MOTOR INTERMOT

DIRECTION VALVE VICKERS

COMPUTER MIRLE 9118

AC CONTACTOR SCHNEIDER

ELECTRONIC RULER NOVO

LUBICATION PUMP HERG

Quick Details

Condition: New

Type: Other

Style: Horizontal

Brand Name: LOG

Model Number: LOG-160A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 260---368G

Clamping Force: 1600KN

Opening Stroke: 430MM

Power(W): 15kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

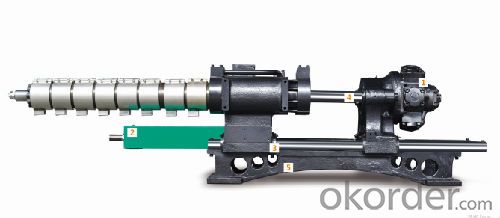

LOG160-A8 energy-saving plastic injection moulding machine

| Description | Unit | LOG-160A8 | ||

| international recognized models | 525/160 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 277 | 318 | 392 |

| Shot volume | g | 260 | 298 | 368 |

| Oz | 9.1 | 10.5 | 12.9 | |

| Screw diameter | mm | 42 | 45 | 50 |

| Injection diameter | mpa | 190 | 166 | 135 |

| Screw L:D ratio | 21.4:1 | 20:01 | 18:01 | |

| Scerw steoke | mm | 200 | ||

| Screw rotate speed | r/min | 0-200 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 1600 | ||

| Opening stroke | mm | 430 | ||

| Platen size | mm*mm | 680*680 | ||

| Space between tie bars | mm*mm | 460*460 | ||

| Maldthickness | mm | 180-500 | ||

| Platen Mix stroke | mm | 930 | ||

| Ejection stroke | mm | 140 | ||

| Ejcetion force | kN | 50 | ||

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 18.7 | ||

| Heating power | kw | 12.6 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 2 | ||

| Tank volume | L | 210 | ||

| Machine dimesions | m*m*m | 4.95*1.25*2.0 | ||

| Weight of machine | kg | 5100 | ||

- Q:Commissioning process of injection molding machine

- 3. calculate the relative viscosity of the plastic with the reciprocal of the filling time multiplied by the peak pressure value. The reciprocal of the filling time is the abscissa, the relative viscosity is the ordinate, and the relative viscosity is plotted. The viscosity curve can be found in the low speed high speed changes more, little viscosity change, find a middle viscosity curve trend in value from flat as we used for the production of fire, (also can be judged according to the change of filling time of plastic viscosity stability when the filling time changes, the peak pressure is small) to overcome the rubber mold flow resistance when the pressure, but also beer pieces of the actual pressure, we use this value is greater than 10% for injection pressure.4. determine the pressure and speed, then come to the switching point, do the packing and feeding in beer 95% ~ 99% position switch for holding position. (padding should be controlled by position rather than pressure or time)5. the filling time should be constant, the injection time is longer than the filling time, so as not to be controlled by time, for example, the injection time, whether it is 4 seconds or seconds, the filling time is about 1 second.6. in this way, the filling time and the holding time can be set up. The average injection time is 0.5 seconds longer than the filling time, and the other can be used as the holding and filling time.

- Q:What kinds of oil are used in the injection molding machine?

- If there is a gear box to use gear oil. All in need of injection molding machine lubricating oil: hydraulic oil, gear oil and hydraulic oil: cuori HM anti-wear hydraulic oil, No. 46, Pu HM hydraulic oil 46 HF-2 hydraulic oil - 46 replacement cycle: a few months. Use time, the answer is basically oil dirty, and other parts of the bearing grease, water, cleaning oil. Recently I went to see many customers, plus two main tanks. Wait, use No. 68 anti-wear hydraulic oil. Hydraulic oil。The exchange of trouble. Why change the oil and so on?,There are also die-casting, oil change time, we are not sure, the general minicomputer is a fuel tank. The machine has instructions.

- Q:What's the meaning of the connection between the injection machine and the manipulator?

- 1, 2, 3 power supply4, 5 is the contact output signal (allowing opening), should be connected to the mold valve6, 7 is the contact output signal (allowing die closing), it should be connected to the valve in series8, 9 is the contact output signal (allowing the ejector die), should be connected to the ejector valve10, 11 is the injection machine to return the signal, tells the manipulator to open the mold to complete13, 14 is the injection machine return signal, tell the robot safety door closed15, 16 is the contact output signal, and the recirculation beginsAccording to the actual circuit of the injection molding machine to analyze how to connect the line,

- Q:Vertical injection molding machine in the semi-automatic state, not sol, and sometimes sol is very slow, seems to be very difficult, and sometimes simply do not turn. The problem is that it occurs during normal use, so the temperature should be fine. The parameter should be OK, too. I removed the screw and cleaned it. There was no foreign object. Under manual operation, the sol is very smooth. Consult an expert.

- First of all, you can look at you in the melt, screw rotation, the system pressure gauge to meet the pressure you set, if not achieved, that is, the system pressure is out of orderAnd then you are in the process of melting, whether there is abnormal sound, if there is the adhesive, motor seat inside the bearings damagedNext, look at your material is doped with excessive toner and so onFOMTEC plastic, I hope to help you

- Q:What's the meaning of "loosening and retreating" before injection machine?

- Small is relatively loose, loose retreat is to prevent the flow of material out of the back too much air inside, back too little will flow out, under the influence of the quality of the first mock exam.Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q:How is the screw speed of injection molding machine adjusted? Who knows very well?.

- Injection molding machine screw speed, first, adjust the injection molding machine pre molding pressure and flow, and then adjust the back pressure

- Q:Injection molding machine maintenance Daquan books catalog

- The third chapter is the mechanical drive system of injection molding machineSection 1 Structure of injection moulding machineI. outline structure of injection molding machineTwo 、 mould locking device of injection molding machineThree. Injection device of injection molding machineThe second section is the assembly relation of the mechanical deviceMould clamping deviceTwo. Dispensing unitThird disassembly and installation of mechanical devicesFirst, the dismantling steps of the die locking deviceTwo. The dismantling step of the spraying deviceFourth, mechanical transmission system maintenanceI. common failures and treatment of mechanical transmission systemTwo. Components and inspection of mechanical drive systemThe fourth chapter is the hydraulic transmission system of injection molding machineSection 1 hydraulic oil pumpSecond section hydraulic cylinder and hydraulic motorThird section hydraulic control valvePressure control valveTwo 、 flow control valveThree 、 direction control valveFour, proportional valveFive. Cartridge valvesFourth section auxiliary deviceDisassembly and overhaul of fifth hydraulic system componentsI. disassembly and inspection of the oil pumpTwo 、 seal and repair of cylinderThree, oil valve repairSixth section hydraulic transmission system common breakdown and processing

- Q:transparent parts inside the bubble, how to solve this problem, non -, what is the cause?

- First of all, we should first analyze where this gas comes from, and how to prevent and reduce the generation of gas.First, when the particles melt in the screw, it will produce smoke. Second, the mold cavity itself contains air, at the time of injection if the air line out will be wrapped into the material to. Third, the moisture in the material produces water vapor at high temperature. (do not think that the drying temperature and time are enough, it must be dry, and wet weather will not be dried by ordinary dryers)From these three directions to improve, first, reduce the material temperature (reduce the production of smoke). Two, slow down the injection rate (which is good for the exhaust gas). Three increase mold temperature (improve material flow due to lower material speed). Four, fully guarantee the drying of materials (PC and PA66 moisture content must be less than 0.03%). Five, the mold into the glue point to enlarge (conducive to the actual effect of packing). Six, the increase in back pressure (effectively increase the density of the material). Seven, the mold exhaust should be guaranteed.From the above points by item examination and improvement, the problem will certainly be solved.In addition, just look at the picture, playing this bubble, the process must be a problem.

- Q:How can I adjust the mold automatically when there is foreign matter in the mold? How about the location of the front and rear die blocks?. Be detailed and simple

- Mode of clamping: fast --- slow --- low voltage --- high pressureInjection molding machine for different brands of different clamping structure is different, but also the same; for example (Taichung) adjusted low before high pressure and high pressure to adjust the position, such as the pressure - adjusting the thickness of die OK---- high voltage setting 70BAR high voltage position return to zero, the locking location data is then set - such as 20.5-- with 0.2 locations - set high - low voltage setting depends on the thickness of the product +1.0 cm - low pressure by 0 to start a +1 pressure low pressure test, the clamping motion not close up (low pressure, not recommended more than 8 special mould except) - in turn to see the lock mode low pressure die - if time is 0.8 seconds and 0.2 seconds on this basis, low pressure time is 1 second.Hope to be of help to you

- Q:How to repair the injection machine?

- Common faults in the use of injection molding machines and solutions are as follows:Part 1: Problems and treatment methods of mould locking parts:(1) not locking dies:Handling method: 1) check the front travel switch of safety door and repair it.2) check the 24V5A power in the electric box, replace the insurance and the power box.3): check whether the spool is stuck, cleaning the spool.4): check whether the output of the I/O board, the solenoid valve is charged.5): check whether the hydraulic safety switch is closed, whether the mechanical lock rod is opened or not.(two) the opening and closing of the die machine:Handling method: 1) check whether the lubricating oil pipe is broken or, if so, reconnect the tubing.2): small amount of lubricating oil, lubricating oil amount increase, 50 die once or manually add oil and lubricating oil.3): clamping force, check whether the mold needs large clamping force, lower the clamping force.4): the current fluctuation of the amplifier board, check whether the current parameters meet the acceptance criteria, re adjust the current value.5): parallelism error indicator check head board parallelism is greater than the acceptance criteria; adjust the parallelism.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Injection Molding Machine LOG-160A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords