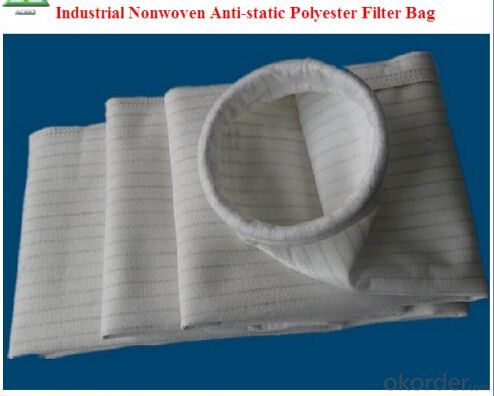

Industrial Nonwoven Needle punched Anti-static Polyester Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications:

Compositions | polyester fiber | |

Weight (g/ m2) | 500 | |

Thickness (mm) | 1.8 | |

Air permeability (L/m2/s) | 150-300 | |

Tensile strength | 1200 | 1250 |

1300 | 1350 | |

Tensile Elongation(%) | <20< span=""> | <30< span=""> |

<45< span=""> | <30< span=""> | |

Broken strength | 2.40 | |

Continuous working temperature(°C/°F) | 140/284 | |

Short time Working temperature(°C/°F) | 160/320 | |

Anti-acid | Excellent | |

Anti-alkali | Excellent | |

Anti-abrasion | Excellent | |

The stability of water solution | good | |

Finishing treatment | Singeing, calendaring, plain, Heat Set | |

Top load/ entry(walk-in plenum) | Snap Band | |

Bottom load/ entry(common in bin vents) | Disk With Wear Strip | |

Heat Setting

Basically all needle felts at Shandong Aobo are heat-set.

The residual shrinkage is reduced to a minimum by means of an optimum combination of the decisive quality factors , such as temperature, dwell time and cooling phase.

The controlled process management during the cooling phase ensures that the filter bags will have excellent form stability even under most difficult conditions.

Quality-determining parameters

Temperature

Reaction time

Cooling time

Thermal surface treatment

The surface of any needle felt influences the structure of the filter cake, its cleanability as well as pressure drop and the emission.

- Singed

Three different kinds of treatment are possible:

smooth for adhesive and moist dust

medium for universal treatments

rough low agglomeration or fine dust

- Calendering

Through calendering a more compact fiber structure is achieved. This allows a more surface-active separation of dust with lower emission.

Protective Impregnation

- hydrophobic, oleophobic

This treatment makes it more difficult for moisture to penetrate into the needle felt. Thus the risk of excessive dust deposits and caking is reduced.

- Protection against acids and hydrolysis

Special impregnation based on TEFLON®. This treatment coats the fiber surface, thus providing it with the anti-adhesive character of a PTFE finish.

An oil- and water-repelling effect is produced, and the fibers are effectively protected against acid and hydrolysis attack.

- Active finish, hydrophobic

Special water-repellent treatment providing a high cleaning and separation efficiency.

Coatings

Through the filter-active coating dust is already separated on the surface. In addition the anti-adhesive surface reduces the adhesive forces between the filter medium and dust cake.

Advantages

Optimised cleaning

Increased service life

High separation efficiency

PTFE-Coating, hydrophobic and oleophobic fibers, protection against acids and hydrolysis

Primary finish membrane, microporous foam coating, high separation efficiency, easy dust release, hydrophobic and oleophobic

Antistatic Constructions

electrical conductive

Optimum discharge of electrostatic charges, therefore suitable for potentially explosive areas, as well as for electrostatic, strongly chargeable/charged dusts.

permanent electrical conductive in accordance with DIN 54 345 part 1 by adding stainless steel fibres into the fibre mass in accordance with DIN 54 345 part 1 or

alternative in support of scrim in accordance with DIN 54 345 part 1 and part 5

Packaging & Shipping

Company Information

- Q:How to use a home cleaner filter bag properly

- Important problems in maintenance. Use a vacuum cleaner to clean the carpet to move in the direction of the wool of the carpet, so absorb dust to maintain the level of carpet wool, It won't break the carpet.

- Q:What is the effect of a dust filter bag?

- The dust is attached to the outer surface of the filter bag. Dust and dust are collected in the outer surface of the filter, while the clean gas is filtered through the filter.

- Q:How is the filter bag chosen?

- Second, if the protecting temperature degrees must be dropped to below 150 ℃ higher investment or restricted by the site; Three is due to gas containing dust because of containing sulphur ingredient, in protecting gas with acid "" dew point "protecting gas can only be in the form of acid dew point temperature is high above the filter elements such as separation, under so much demand have a chemical fiber can endure high temperature dust removal filter bag filter material used to make dust removal."

- Q:How many types of filters are in the filter bag?

- Flat: the filter bag is flat, including rectangle and trapezoid, which is represented by the perimeter of the length.

- Q:Why is the filter bag material PE a polyester, not a polyethylene

- It is divided into high density polyethylene, medium density polyethylene and low density polyethylene according to the density. Polyethylene is a high polymer chain that is connected by a repeat - CH2 - unit connection through the addition and polymerization of ethylene (CH2 = CH2). Purpose: polyethylene insoluble in water, water is very small, is about some chemical solvents, such as toluene, acetic acid, etc., and only showing modest dissolved when temperature above 70 ℃. But polyethylene particles shape, can be between 15 ℃ and 40 ℃ melting or solidification, along with the change of temperature at higher temperatures melt, absorbing heat; When the temperature drops, it solidifies, releasing heat. Because it absorbs little water, it is not wet, it has insulation, so it is a good building material.

- Q:How about all the filters in the washing machine

- Either use a silk sock instead of using it, or buy a new one after the sale.

- Q:What is the filter bag made of foam tea?

- Hello, this kind of tea bag is used for the high grade filter paper with the combination of log and fiber, this paper is environmentally friendly and easy to handle and easy to use

- Q:How about the filter bag of the washing machine

- If you have a screen of the original filter, put a silk sock on the frame and wrap it around the outside with a strong thread

- Q:Is there a filter bag for the washer?

- Platen washing machine also has a filter bag, it's in the washing machine at the bottom, maomao, hair will collect there, you will see that place on the ground in a washing machine has a small door, it is inside the filter bag.

- Q:What is the cleaning method of the filter bag

- So that's how you clean the filter bag. Have you learned it? One thing you need to be aware of is that you have to choose the quality of the filter, so the filter will be good. In order to select a quality filter, you must go to the hui long filter purification co., LTD. Huilong filtration purification co., LTD. Is a company that "relies on science and technology to revitalize the famous nationality industry, and make a world brand" Culture and "customer first, win-win cooperation". We are always committed to the continuous development of the filter business, continuous development, innovation and progress. Pursue the peak of technology. Create a world class filter "carrier" filter

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Nonwoven Needle punched Anti-static Polyester Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords