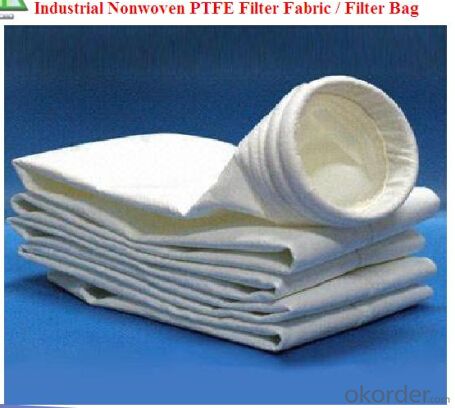

Industrial Nonwoven PTFE Filter Fabric Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications:

The PTFE needled felt is a fiber of extremely stable chemical performance

1,Continuous operating temperatures above 250℃, the instantaneous temperature of 280 ℃.

2, Good acid & alkali resistance and oxidation resistance, non-combustible.

3, The only not aging fiber.

4, Can be used under the most adverse conditions, with extremely long service life, and usually the service life is 4 years.

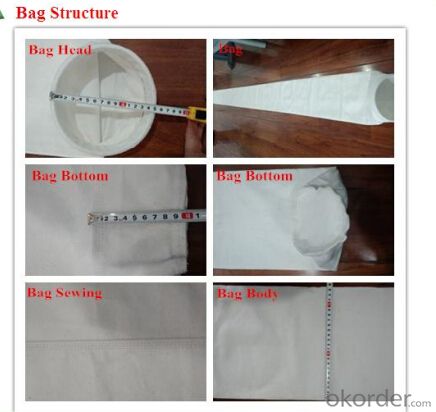

specification

Description of product | TF/TF1750-W |

Fiber | 100%PTFE |

Substrates | 100%PTFE |

Square weight | 750g/m2 |

Thickness | 1.1mm |

Density | 0.68g/cm3 |

Air permeability | 90L/dm2.min |

Breaking Strength-lengthways | ≥450 N/125px |

Breaking Strength-crosswise | ≥450 N/125px |

elongation@200N/125px-lengthways | <5% |

elongation@200N/125px-crosswise | <5% |

Heat shrinkage@150degC,90min | 2% |

Bursting strength | >300 N/cm2 |

Continuous temperature | 260℃ |

Instantaneous temperature | 280℃ |

Post-processing | Heat-setting |

Heat Setting

Basically all needle felts at Shandong Aobo are heat-set.

The residual shrinkage is reduced to a minimum by means of an optimum combination of the decisive quality factors , such as temperature, dwell time and cooling phase.

The controlled process management during the cooling phase ensures that the filter bags will have excellent form stability even under most difficult conditions.

Quality-determining parameters

Temperature

Reaction time

Cooling time

Thermal surface treatment

The surface of any needle felt influences the structure of the filter cake, its cleanability as well as pressure drop and the emission.

- Singed

Three different kinds of treatment are possible:

smooth for adhesive and moist dust

medium for universal treatments

rough low agglomeration or fine dust

- Calendering

Through calendering a more compact fiber structure is achieved. This allows a more surface-active separation of dust with lower emission.

Protective Impregnation

- hydrophobic, oleophobic

This treatment makes it more difficult for moisture to penetrate into the needle felt. Thus the risk of excessive dust deposits and caking is reduced.

- Protection against acids and hydrolysis

Special impregnation based on TEFLON®. This treatment coats the fiber surface, thus providing it with the anti-adhesive character of a PTFE finish.

An oil- and water-repelling effect is produced, and the fibers are effectively protected against acid and hydrolysis attack.

- Active finish, hydrophobic

Special water-repellent treatment providing a high cleaning and separation efficiency.

Coatings

Through the filter-active coating dust is already separated on the surface. In addition the anti-adhesive surface reduces the adhesive forces between the filter medium and dust cake.

Advantages

Optimised cleaning

Increased service life

High separation efficiency

PTFE-Coating, hydrophobic and oleophobic fibers, protection against acids and hydrolysis

Primary finish membrane, microporous foam coating, high separation efficiency, easy dust release, hydrophobic and oleophobic

Packaging & Shipping

Company Information

- Q:What is the fabric of a filter bag?

- Forging tissue: according to the surface of the fabric, the warp and weft are divided into the warp and the weft. The texture of the forging texture is smooth, the surface is shiny, very soft, elastic and breathable, and the yarn is easy to clean because of the moving nature of the yarn.

- Q:The filter bag in the washing machine is broken. How do you fix it

- In general, the filter bag of the washing machine can be removed, please read the instructions carefully, even if it is not easy to tear open come down to, as long as don't have much stuff, generally does not affect the quality of washing.

- Q:Why is the filter bag material PE a polyester, not a polyethylene

- Polyester: the general name of a polymer compound that is condensed by diglycol or polyols and dibasic acid or polyacid. Include polyester resin, polyester fiber, polyester acid glue etc. Polyester, Polyethylene terephthalate (PET) belong to the high molecular compound. Consists of terephthalic acid (PTA) and ethylene glycol (EG) through polycondensation produce polyethylene terephthalate (PET), part of the PET and ultimately generated by underwater pelletizing. Purpose: fiber grade polyester chip is used to make polyester staple and polyester filament, which is the raw material for fiber and related products of polyester fiber. Polyester film and bottle, and other purposes at the same time, widely used in packaging industry, electronic appliances, medical and health care, construction, automotive and other fields, the packaging is one of the largest non polyester fiber application market, is also the fastest growth in PET. It can be said that the polyester slice is an important intermediate product that connects the petrochemicals and the products of several industries.

- Q:What materials are commonly used in liquid filtration bags?

- 1, good heat resistance, can be used under 280 ℃ for a long time Dust is easy to peel off The dimension stability is good, the fiberglass itself does not contract at the standard temperature

- Q:Which is the liquid filter bag?

- It's a liquid filter bag that's been filtered by the dragon, so don't be funny. The worst quality is the hui dragon, the price is dead expensive, the filtration efficiency is bad, the speed of change bag is really fast, too bad, roll thick. The best brand is eton. Your ID lit up.

- Q:How can you not damage the filter bag when the filter bag is installed?

- The bag cage should be inspected before the bag cage is installed. No burrs, soldering, welding and deformation are not allowed. After the bag is inserted into the filter bag, the bag should be slowly devolution, the speed of devolution will be cut and the filter bag will not be free fall.

- Q:How do you use a filter bag?

- In order to improve the use of filter bags, we should pay special attention to this knowledge in ordinary times. If we have different problems, we need to find solutions. First, the bag is broken. The shape of the filter bag and the installation method of the filter bag determine the location of the filter bag easily broken, which can be inspected and repaired. Secondly, the filter bags age. For reasons that are caused by the following reasons, reasons should be investigated, taking the elimination measures and changing the filter bags. (1) hardening and contracting due to unusually high temperature; (2) due to contact with the vapor of an acid, alkali or organic solvent; 3) react with water.

- Q:How to check the filter bag and the dust collector bag when the dust collector is installed?

- You say the bag and the bag cage visual inspection before installation needs, from experience observation, at the time of assembly is the detailed inspection, in principle, a bag and bag cage on the diameter is 2.5 mm clearance, need adjustment of clearance is too large. Be careful when you wear a cloth bag. Are you asking about this question, the bag leak check, The method is to apply fluorescent powder to the surface of the phosphor powder, and see if there is any leakage at run time.

- Q:How to buy the paint filter bag in the car painting

- Car paint German parrot paint, of course, you ready to buy on taobao, I will buy, there is very good on taobao input car paint parrot came out. It's in shenzhen. The cleaning machine has extensive application in the area of industrial cleaning, and the car factory should also prepare several, wash the machine wash the paint, the welding slag effect... It is recommended that you use the chengdu lifeng cleaning machine, and the cleaning machine should not only look at the management and maintenance of the latter, but also choose a good brand. The coating site is polluted, such as the floor of the lacquer room is not clean and clean. Poor equipment, no positive pressure in the baking room, filter net... The process of determining the relationship between paint and car color is determined by graphical method. The color is determined only in the car itself...

- Q:How about the filter bag of the washing machine

- If you have a screen of the original filter, put a silk sock on the frame and wrap it around the outside with a strong thread

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Nonwoven PTFE Filter Fabric Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches