Hot Rolled Steel I-Beams with Highest Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

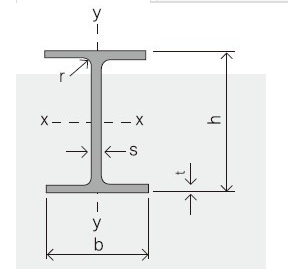

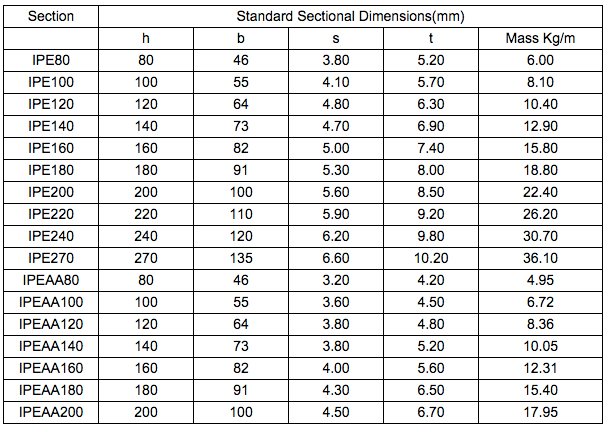

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: The products are invoicing on theoritical weight or on actual weight?

A2: We can do it in both manners, according to the customers' request.

Q3:What's your payment terms ?

A3:Mostly,we collect the money by T/T and LC at sight . We also accept time LC at 90/120 days s

Q4: How do you guarantee the quality of products?

A4: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Images:

- Q:Can steel I-beams be used in data centers or server rooms?

- Yes, steel I-beams can be used in data centers or server rooms. Steel I-beams are commonly used for structural support in buildings and can provide stability and strength required for heavy equipment and infrastructure in data centers and server rooms.

- Q:Can steel I-beams be used in railway infrastructure?

- Yes, steel I-beams can be used in railway infrastructure. Steel I-beams are commonly used in the construction of railway bridges and support structures due to their high strength-to-weight ratio and durability. They provide excellent load-bearing capacity, allowing them to support the weight of trains and other heavy railway equipment. Steel I-beams also have the advantage of being able to span long distances, making them suitable for railway applications where large spans are required. Additionally, steel is a versatile material that can be easily fabricated and welded, making it a practical choice for railway infrastructure projects.

- Q:What are the common challenges in erecting steel I-beams on-site?

- Some common challenges in erecting steel I-beams on-site include the need for heavy machinery and equipment to lift and position the beams, ensuring the proper alignment and levelness of the beams, coordinating with other trades and contractors to ensure a smooth installation process, and addressing any unexpected site conditions or obstacles that may hinder the installation process. Additionally, safety considerations and adherence to building codes and regulations are important factors to consider during the installation of steel I-beams.

- Q:What are the different types of steel I-beam supports?

- There are several different types of steel I-beam supports used in various construction and engineering applications. The specific type of I-beam support chosen depends on factors such as the load-bearing capacity required, the span of the beam, and the structural design of the building or structure. Some common types of steel I-beam supports include: 1. Wide Flange Beams: These are the most commonly used I-beam supports due to their versatility and strength. Wide flange beams have a wider flange section compared to standard I-beams, offering increased load-bearing capacity. 2. S-Shaped Beams: Also known as American Standard Beams, S-shaped beams have a tapered flange section, which makes them lighter and more cost-effective for smaller structures. They are commonly used in residential construction and lighter commercial applications. 3. H-Beams: H-beams, also known as I-beams or W-beams, have a standard flange width and are widely used in heavy construction projects. They provide excellent strength and load-bearing capacity, making them suitable for large-scale commercial and industrial structures. 4. Box Beams: Box beams are hollow rectangular or square-shaped steel beams that offer high strength-to-weight ratios. They are often used in architectural and aesthetic applications where a sleek and modern appearance is desired. 5. Tapered Beams: Tapered beams are I-beams with tapered flanges, which allow for better weight distribution and reduced material usage. They are commonly used in bridge construction and other applications requiring long-span beams. 6. Composite Beams: Composite beams combine steel with other materials, such as concrete or timber, to create beams with enhanced strength and load-bearing capacity. These beams are often used in high-rise buildings and bridges. 7. Plate Girder Beams: Plate girder beams consist of welded steel plates that are joined together to form a strong and rigid beam. They are commonly used in industrial buildings, bridges, and other applications requiring long-span or heavy-load beams. These are just a few examples of the different types of steel I-beam supports available. Each type offers unique advantages and is chosen based on the specific requirements of the project. It is important to consult with a structural engineer or construction professional to determine the most suitable type of steel I-beam support for any given application.

- Q:How do steel I-beams perform in terms of thermal expansion?

- Steel I-beams possess a relatively low coefficient of thermal expansion, enabling them to exhibit strong performance in terms of thermal expansion. This implies that, when confronted with temperature changes, they expand and contract to a lesser degree compared to other materials. The primary reason for the low coefficient of thermal expansion in steel I-beams is the material's inherent properties, which demonstrate minimal expansion or contraction when exposed to heat or cold. Consequently, steel I-beams are highly resistant to warping or distortion caused by temperature fluctuations, rendering them exceptionally dependable and structurally stable in diverse environmental conditions. This characteristic proves particularly advantageous in critical construction and engineering projects that demand precise measurements and stability. In summary, steel I-beams are widely recognized for their outstanding thermal expansion properties, which contribute to their extensive utilization across various industries.

- Q:How are Steel I-Beams connected together?

- Different methods are used to connect steel I-beams, depending on the application and structural needs. Welding is a common technique, where heat and pressure join the flanges and web of the I-beams to create a strong and permanent connection. This seamless and continuous connection ensures the structure's integrity and stability. Another method is bolting, where bolts, nuts, and washers are used to connect the beams. Holes are drilled through the flanges and web, and bolts are inserted and tightened for a secure connection. Bolting allows for easy disassembly and modifications, offering flexibility in connecting I-beams. In some cases, a combination of welding and bolting is used. This hybrid approach provides additional strength and stability while offering some flexibility and adjustability. It's important to note that the specific method of connecting steel I-beams may vary depending on the structural design, load requirements, and type of steel used. Professional engineers and fabricators consider these factors to determine the most suitable connection method for each project.

- Q:Can steel I-beams be used for green or sustainable building projects?

- Yes, steel I-beams can be used for green or sustainable building projects. Steel is a highly recyclable material and using steel I-beams in construction can help reduce the environmental impact. Additionally, steel is durable and long-lasting, requiring less maintenance and replacement compared to other materials.

- Q:How do steel I-beams contribute to the overall sustainability of a structure?

- Steel I-beams contribute to the overall sustainability of a structure in various ways. Firstly, they have high strength-to-weight ratios, allowing for efficient use of materials and reducing the amount of steel required, which in turn conserves natural resources. Additionally, steel is 100% recyclable, and I-beams can be easily dismantled and reused, reducing the demand for new materials and minimizing waste. Furthermore, steel I-beams are durable and long-lasting, requiring minimal maintenance over their lifespan, which reduces the need for replacements and further conserves resources. Overall, the use of steel I-beams promotes sustainability by optimizing material efficiency, supporting recycling efforts, and ensuring longevity of the structure.

- Q:Can steel I-beams be used in aviation or aerospace construction?

- Yes, steel I-beams can be used in aviation or aerospace construction, although they are not commonly used as the primary structural component. Steel I-beams are known for their strength and durability, making them suitable for various applications. In aviation and aerospace construction, however, weight is a critical factor, and steel is relatively heavy compared to other materials such as aluminum or composites. Therefore, while steel I-beams may be used in certain specialized areas or secondary structures where weight is less of a concern, the primary structural components in aviation and aerospace construction are typically made from lighter materials to optimize fuel efficiency and performance.

- Q:Can steel I-beams be used in cultural or historical buildings?

- Yes, steel I-beams can be used in cultural or historical buildings. While traditional materials like timber or masonry are often associated with cultural or historical buildings, steel I-beams can provide numerous advantages in terms of structural integrity, flexibility, and cost-effectiveness. Steel I-beams offer high strength-to-weight ratio, allowing for large open spaces and long spans without the need for excessive columns or supports. This can be particularly beneficial in cultural or historical buildings that require large, uninterrupted spaces for exhibitions or performances. The use of steel I-beams can also allow for the incorporation of modern amenities, such as HVAC systems, electrical wiring, and plumbing, without compromising the historical integrity of the building. Furthermore, steel I-beams are highly durable and resistant to fire, pests, and decay, making them suitable for preserving cultural or historical buildings for generations to come. They can be easily fabricated, assembled, and disassembled, allowing for efficient construction and potential future modifications or additions. However, when considering the use of steel I-beams in cultural or historical buildings, it is crucial to strike a balance between modern functionality and preserving the historical character. Architects and engineers must carefully assess the specific requirements and sensitivities of each building to ensure that the use of steel does not compromise its authenticity or cultural significance. Overall, while traditional materials will always hold cultural and historical value, steel I-beams can be a viable option in certain contexts, offering structural strength, flexibility, and longevity that can contribute positively to the preservation and adaptive reuse of cultural or historical buildings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel I-Beams with Highest Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords