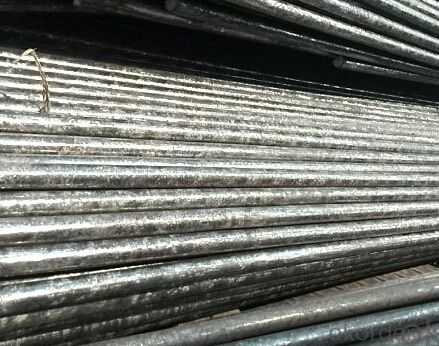

High Qulity Stainless Die or Mould Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering High Qulity Stainless Die or Mould Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Qulity Stainless Die or Mould Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's High Qulity Stainless Die or Mould Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Die steel was used in the manufacture of cold die, hot forging molding moldmold. The mould is the main processing tool manufacturing parts of machinery manufacturing, motor, electric instrument, radio and other industrial sectors in the. Mold quality directly affects the pressure processing technology, the precision of the product yield and quality of production cost, and the quality and service life of die except by reasonable structure design and machining precision, mainly affected by mould material and heat treatment.

Introduction

Die steel can be broadly divided into: cold die steel, hot die steel and plastic mould steel three class, used for forging, stamping, cutting type, die castingetc.. Because of various kinds of mold for different purposes, the workcondition is complex, so the mold steel, mold manufacturing according to theirworking conditions, should have the strength, hardness, high wear resistance,enough toughness, and high hardenability, hardenability and other process performance. Because this kind of different purposes, the complex working conditions, so the die steel performance requirements are also different.

Cold mould comprises a die, drawing die, drawing die, stamping die, thread rolling die, thread rolling plate, Leng Dunmo and cold extrusion die etc.. Mold steel cold work, according to the manufacture working conditions, have high hardness, strength, wear resistance and enough toughness, and highhardenability and hardenability and other process performance. For this kindof alloy tool steel for use in general belong to the high carbon alloy steel,carbon content was above 0.80%, chromium is an important alloying elementof this kind of steel, whose content is usually not more than 5%. But for somewear resistance requirement is very high, quenching after deformation is smalldie steel, the highest CR mass fraction of 13%, and to the formation of a large number of carbide, carbon content in steel is also very high, up to 2.0%~2.3%.Cold working die steel with high carbon content, the organization mostlyhypereutectoid steel or ledeburite steel. Steel commonly used with high carbon and low alloy steel, high carbon high chromium steel, chrome molybdenum steel, medium carbon chromium tungsten Bracelet steel etc..

Hot die forging, divided into hammer forging, extrusion and die-casting of several main types, including hot forging die, press forging die, stamping die,hot extrusion die and metal die casting die. Thermal deformation die at work in addition to bear great mechanical stress, but also bear the repeated heating and cooling do use, and caused great thermal stress. Hot work die steelshould have high strength, hardness and red hardness, wear resistance and toughness, but also should have high strength, good thermal stability, thermalfatigue resistance and corrosion resistance, also has high hardenability, so as to ensure the whole section has the mechanical consistency can. For die casting die steel, also has a surface layer after repeated heating and coolingdoes not crack, and subjected to liquid

Die steel

State of the metal flow impact and erosion performance. This kind of steel is usually belongs to the medium carbon alloy steel, carbon content in 0.30%~0.60%, belongs to the sub eutectoid steel, there is also a part of steelas the alloy elements added more (such as tungsten, molybdenum, vanadium,etc.) and become the eutectoid or hypereutectoid steel. Steel commonly used with chromium manganese steel, chrome nickel steel, chromium, tungsten steeletc..

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q:What is the mold for?

- As mentioned before, the plastic forming theory and mathematics modeling is not perfect, caused by stamping process analysis and formulation in the design phase is not perfect, need bench late a large number of debugging, this problem may be irremediable solution for, still can reason to evade a responsibility appropriately for designers, but the mechanical structure of the mould level is not good, for the kind of "line", as if we would be a little difficult to quit the effect, of course, I think it's also have many causes. First of all, the more high-end mold mechanical structure generally applied in complex parts and processes, such as car side plate, wing plates, engine hood pressing parts, such as domestic auto manufacturers due to many reasons such as sino-foreign joint venture, it is difficult to make the domestic mold enterprise manufacturing this kind of product of mold, new models of similar parts is often deprived, so we seldom opportunities for actual combat, some powerful manufacturers can be less in production tasks, practice habits conducted theoretical design, heaven knows earth knows the final effect is people do not know!

- Q:The function of die water board?

- The waterboard is a couple of pulling needles, which bring the water out.

- Q:What is the top and bottom die in the mould?

- Hello, before you answer your question, I want to tell you that you are just as misguided as any other student. Moulds itself no, under the touch, it's like: two tiles together, we can't say targeted on brick, brick, if there is a mould of lower die on concept, studied physics knows, it is need a reference or a reference point. Two cavity, the most common type of mold is the so-called two mould, is there are two main cavity, you can control open mould, also can open mould, therefore, only under the condition of upper and lower mould work, just have upper die, the meaning of the lower die.

- Q:Can you tell me how the injection molding machine has a large closing line and the batch front?

- Moulding line big flash, must first rule out the mould with no problem, with red lead powder with the mold can be ruled out, if the parting surface not fully fit after clamping to have crack, can produce big flash. It is not a problem to exclude the mold, the process consideration: 1, the material flow is too good, the cylinder temperature is properly lowered

- Q:What is a mold bite

- The molds of molds are treated with the surface corrosion reaction of the steel surface, such as concentrated sulphuric acid, forming the skin/erosion/pear ground or other forms of grain.

- Q:The difference between wire cutting and mold making

- Line cutting and molds: linear cutting is a process that can cut the conductive material into the desired shape. Edm Wire cutting machine, Wire Electrical Discharge Machining WEDM), electric processing category, is by the former Soviet union cluster technology limited couple lazarus research by spark Discharge switch contact corrosion damage phenomenon and reason, found that spark of instantaneous high temperature can make local metal melting, oxidation and corrosion, so as to create and invented the electric spark Machining method. The line cutting machine was invented in the former Soviet union in 1960 and is the first country to be used in industrial production.

- Q:Basic knowledge of die fitter

- Introduction to the bench The fitter is the method of machining by hand. 2. The characteristics of the bench has three major advantages, flexible processing, processing complicated shape and high precision parts, small investment), two big weaknesses (low production efficiency and the intensity of labor and processing quality is not stable). (1) working flexibly in a machine that is not suitable for machine processing, especially in the maintenance of mechanical equipment, the work of the fitter is satisfactory. (2) for processing complicated shape and high precision parts skilled bench can work out better than modern machine tool parts processing precision and the bright and clean, can work out the shape of even modern machine tool will not be able to process the complex parts, such as high precision measuring tool, mould, beginning complex, etc. (3) the equipment and equipment used for the processing of small fitter are cheap and convenient to carry. The production efficiency is low, the labor intensity is large

- Q:How can silicone and glass steel molds be glued together

- Make plaster mold silicone mold cost is higher, soft silicone mold die, must be listed hard mold industry is hard glass fiber or plaster mold to play a role in the tray, so the cost in terms of silicon rubber, no doubt, the cost will be higher. But FRP mould, despite the cost is relatively low, but because it is a hard mold, difficult mold, also must do slice mode, there are few FRP mould is not very complex, which makes them very trouble. The silicon rubber moulds, on the other hand, are easy to make, prone to mold, and very fine molds, which make the head even a hair.

- Q:How long is the life of die casting die?

- Aluminum: 120000 times Copper: 20000 times Magnesium: 200000 times Zinc: 500000 times Benchmark, the product structure added and reduced die life

- Q:What is the pull mold

- The drawing die is also called drawing die, which is used to pull metal plates deep into cups or curved parts. For example, small metal cups or large car body shapes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Qulity Stainless Die or Mould Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches