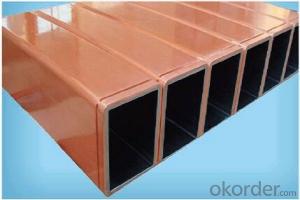

High density Purified Copper Alloy Ingot Casting for Steelmaking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: High density copper alloy ingot

Type Specifications: T2, TU1, TU2, TP2

Produced by low-vacuum copper smelting casting technology with its intellectual property right owned by Feichi Copper & Aluminum; high density and high purity product with low hydrogen and oxygen content, usually processed into copper products of various shapes and widely applied in steelmaking, electric power, shipbuilding, and machinery sectors

Application:

Produced by low-vacuum copper smelting casting technology with its intellectual property right; high density and high purity product with low hydrogen and oxygen content, usually processed into copper products of various shapes and widely applied in steelmaking, electric power, shipbuilding, and machinery sectors

Special Shaped tungsten products

We produce special shaped tungsten products and other OEM products.

Production Equipment

750-1500kg main frequency induction copper melting furnace, 80MN water seal extruder, LG60 high speed two-roll cold pilger mill, straight-line wire-drawing machine, copper tube/pipe straightener, polisher, 84′ copper coil winding machine, straightening-cutting & pancake coiling machine, thermoplastic packaging machine, 1.2T continuous bright annealing furnace.

80MN extruder

Continuous bright annealing furnace

Testing Devices

spectrum analyzer, atomic absorption analyzer, spectrophotometry, analytical balances, metallurgical microscope, eddy current flaw detector, metal tensile testing machine, eddy conductivity instrument.

Hardness tester

Spectrum analyzer

Metallurgical microscope

Metal tensile testing machine

Atomic absorption analyzer

Process

refined copper — smelting & casting — extrusion — rolling — drawing — straightening-cutting/forming of pancake coil — bright annealing — packaging — finished goods.

Standards

GB/T 1527-2006 Drawn tube of copper and copper alloys

GB/T 16866-2006 Dimensions and tolerances of copper and copper alloy seamless tubes

GB/T 4423-2007 Copper and copper-alloy cold-drawn rod and bar

GB/T 5231-2001 Wrought copper and copper alloys chemical composition limits and forms of wrought products

GB/T 5585.1-2005 Copper or aluminium and its alloy bus bars for electrical purposes—Part 1:Copper andcopper alloy bus bars

GB/T 17791-2007 Seamless copper tube for air conditioner and refrigeration equipment

GB/T 19850-2005 The seamless round copper tubes for electrical purposes

GB/T 26024-2010 Seamless copper and copper alloys tube for valves on air-conditioning and refrigeration system

ASTM B280-2008 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

EN 12735-1:2001 Copper and copper alloys Seamless,round copper tubes for air-conditioning and refrigeration Part 1:Tubes for piping systems

EN 12735-2:2001 Copper and copper alloy – seamless round copper tube/pipe for air-conditioning and refrigeration system – for equipment

JIS H3300-2009 Seamless copper and copper alloy tube/pipe

- Q:I would like to know if anyone has a ruff idea of the timeframe it takes for copper or brass to melt in a waste oil furnace. I am using a #8 crucible and can fit about 7lbs of either material in it at a time. I know that using propane it can take about 45 minutes but since I am using waste oil and it is direct heat surely the timeframe must be less.

- nope, propane will get hotter than waste oil, because its a gas already, the oil has to heat up to burn hotter, [convert its self to a gas] Mapp gas will get even hotter, i use it to braze alum, it has to be at 780 deg to start it , melting,

- Q:I just recently got a Copper Rollers bit from my aunt. I ride a 4 year old Arab and she likes to chew and play on the bit. What would this bit do? Would she prefer this bit over the full cheek snaffle that I use on her?This is what it looks like

- if she is going well, why change? horses need consistency all the time. going well in a snaffle is the ideal. a bit with copper rollers is a soft bit meant to encourage horses to salivate so the bit would be able to move more easily in their mouth. it would make her play with it more too. if she already does that without it, then she doesn't need it. copper can also be illegal for showing as well. don't fix it if it isn't broken.

- Q:I know that it is not related to the AC unit or the water heater.

- You have a leak. Have a plumber fix it.

- Q:I bought an antique copper hip flask from Portebello market (London), when I washed it out with water loads of grime came out. Is it safe to drink hard liquor from it or will I get some sort of copper poisining? I've washed it out with boiling water and fairy antibacterial washing up liquid, what would you recomend I do? thanks in advance :D xx

- Is the flask lined with another metal other than copper, IF NOT, don't use it as you could get cooper poisoning...yes I am serious....If it is lined then use a vinegar,soap &water solution and let it set for a few hours to a day, then rinse it out and clean well, repeat if necessary,if possible use a bottle brush to help get inside.... Be CAREFUL if the flask is not lined, adding liquor (whiskey)is similar to adding bleach to it and drinking it as the alcohol will have an adverse affect on the copper. IF needed contact a copper smith. ntact PAUL REVERE COOKWARE as they use a lot of copper in their products for advice.

- Q:I need to remove a sharkbite fitting from a copper pipe. I have a female part connected to the copper pipe and need to remove that to attach a male fitting which in turn will attach to a three way valve i bought. The question i have is that i have the removal tube, but the pipe isn‘t long enough in the back for me to grab and twist with the removal tool. Can I use a crescent wrench to mimic the turning action on the back, or how should I approach this to remove the sharkbite fitting? Thanks.

- Removing your pipe from a Sharkbite? fitting is simple with these tongs Step #1:[Tong removal] Grip the Sharkbite? fitting with the tongs, squeeze the Sharkbite? fitting depressing the release ring Step #2:[Pipe Inserted] Rotate the pipe 90°, rotate again and simultaneously remove the pipe from the fitting

- Q:My single story house was built in 1955 on a slab. My stub outs are iron pipe. What kind of plumbing pipe is running through my slab, iron or copper? I always thought it was copper, but why the iron stub outs?The reason I ask is that I‘m going to change my angle stop valves and want to know if I need to apply much counter torque when I remove them from the 1/2 MIP stub.Thanks!!

- by house built in 1957 has copper from where it comes threw the floor to the meter yours maybe copper with mip flanges to your Iron pipe

- Q:Outside of air conditioning machine copper pipe freezes and does not refrigerate what reason is it?

- Air conditioning rough pipe icing:1, air conditioning fan speed is too slow or radiator dirty, cause air conditioning rough pipe icing. Detect the damage or performance of the fan in time, and clean the radiator in time.2, the air conditioning system is slightly deficient fluorine or the environment is too low to cause; in time to the air conditioning fluorine.3 、 excessive dust or clog of air conditioning system:Air conditioning filter dust is too much, regularly to air conditioning cleaning. Air conditioning pipe blocked, bent or deflated, resulting in air conditioning pipe icing; check out.

- Q:Anyone have experience with the SharkBite Connection System, which requires no soldering? If so, what is your opinion of it?

- I remodeled my kitchen recently and did all the work myself. I used PEX instead of copper and Sharkbite connectors. I was surprised to learn that many professional plumbers are using them also. They are very easy to use, guaranteed for 75 years and, so far, no leaks. Follow the directions and take care to make clean, straight cuts and I think you will like way things turn out. I also used Gatorbites (one is from Lowes the other from Home Depot) and could not tell the difference. Good luck and enjoy the project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High density Purified Copper Alloy Ingot Casting for Steelmaking

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords