Form Traveler

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Rhombic Traveler

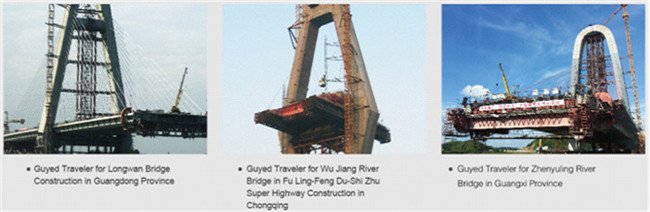

2.Guyed Traveler

3.Triangle Traveler

4.Through Supported Traveler

5.Normal Traveler

Products Introduction & Application:

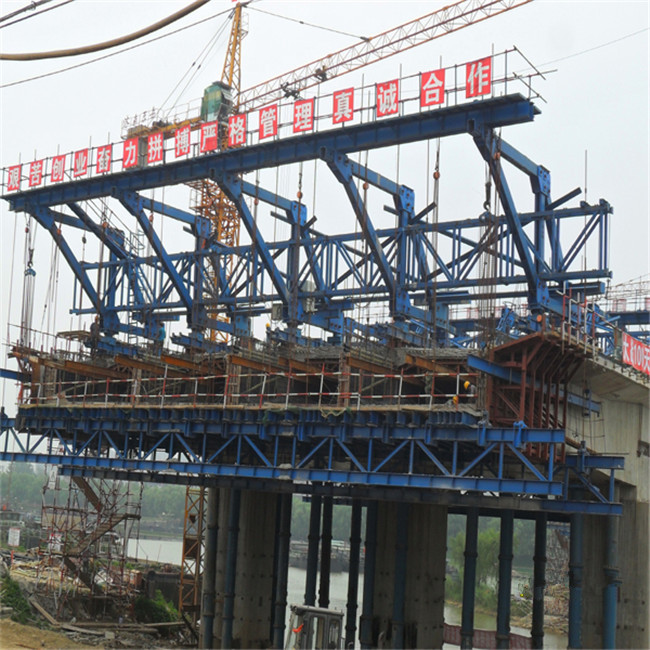

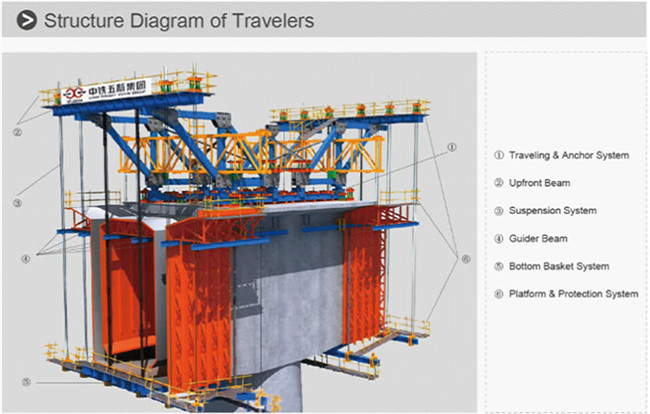

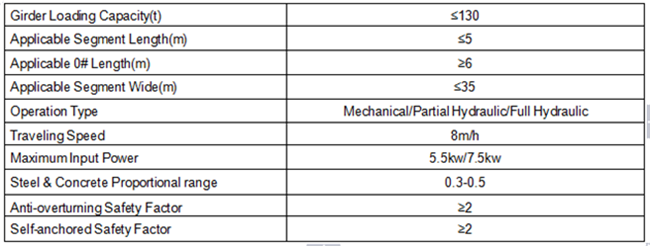

Form traveler is the major equipment used in cantilever construction. The product we developed is consist of main girder system, traveling system, anchor system, bottom basket system, suspension system, platform & protection system, formwork system, hydraulic system(optional) and so on. All the parts are self-contained, interdependent and interrelated, already awarded over 20 authorized patents.

In order to improve universality and utilization, reduce purchasing cost, and enhance security & reliability, we provide the series service of “designing, detecting, renting and constructing form traveler service as well as technical assistance & training.” Today 800 T-structure form travelers can be provided for renting service.

Projects:

- Q:Hanging basket in the construction of the 2 block construction is also need to press it

- 6 when you walk in the basket, be sure to move smoothly.7 cantilever pouring concrete should be from the basket to the front of the basket to the end of the basket.8 jack is an important tool in construction, must be carefully maintained.9 walking system should be lubricated regularly.

- Q:I would like to ask: how to choose the kind of hanging basket? Do their own basket design and production for 2 years, but do is diamond, triangle hanging basket and diamond hanging basket, etc.

- Personal feeling diamond good point, because used a few diamond. The triangle is also seen, mainly to see how the design, such as the design of track running system as long as easy to use is good

- Q:What should be paid attention to in the construction of cast in place box girder of long span bridge hanging basket

- Main cause:1) no sprinkler health;2) the thermal insulation performance of the template is not good, the temperature difference between inside and outside is too large.

- Q:Construction scheme of hanging basket

- The construction scheme of rhombic truss type hanging basket: a brief introduction of the main structure of the main bridge of the North Branch bridge of Nanjing Second Yangtze River Bridge is 90+3*l65+90 (m) of the five span prestressed concrete continuous box girder. The main span of 165m is the first in the same type of bridge in china. According to the design requirements, the construction method needs to use cantilever pouring construction technology and then through the closure and system conversion into continuous beam

- Q:How does the prestressed tensioning in the construction of the bridge hanging basket?

- Simple introduction of hanging basket construction:1 steel cable-stayed bridge construction, most of the factory welding, transported to the site, with the crane as a whole lifting, or block lifting, in place after the formation of high-strength bolts.2 construction of concrete cable-stayed bridge with cast-in-place and precast assembly and other combinations of construction technology.

- Q:The definition of hanging basket construction, historical background

- Construction craft: 1 hanging basket hanging void, at this point the anti force downward force to the hanging beam hanging basket, hanging basket and the longitudinal beams under negative bending moment. 2 hanging basket forward, hanging basket still bear negative moment, a single arm state. 3 hanging basket beam lifting, after anchorage anchorage, the hanging basket is in place, after the anti point elevation roughly leveling, set preraised height. The 4 cable is connected with the hanging basket, and the first cable tension is carried out, and the front pivot point of the hanging basket is stressed. 5 to the 1/2 beam section for the second cable tension. When the concrete beam of the 6 section is completely cross section, the elasticity of the end of the basket is less than the specified value. 7 detect the beam elevation, the concrete strength to reach the tension of prestressed beam. 8 hanging basket to be moved forward.

- Q:What are the innovative points of hanging basket construction

- Construction control points of concrete pouring basket:1 tamping is not dense, not dense, missing tamping concrete honeycomb;2 both ends of the section pouring speed is not the same, resulting in unbalanced force;3 pouring operations caused by the deformation of the prestressed channel deformation, deflection, etc.;4 concrete upper and lower intervals for too long, resulting in construction joints;

- Q:I would like to know that each piece of the construction of the hanging basket is connected by way of the whole as a whole, I always think of each section is a section of tension.As you said, the steel strand is the length of the whole beam, but how to form the whole concrete?

- The segments are tensioned, but many of the prestressing tendons are common, or through several segments

- Q:I would like to ask a joint (32m+48m+32m) continuous beam cantilever hanging basket perfusion, each phase of the most reasonable construction cycle is how long (in days), thank you

- Continuous beam of a block of the construction period of about 10 days to about 12 days, the 10 day is a bit illegal operation

- Q:Production and installation of hanging basket

- In the construction, the construction quality of the corrugated pipe is good or bad, how to ensure the construction quality of the bellows? The main management measures are as follows:8.1. inventory. Bellows transported to the construction site, to enter the warehouse room stacked with the lower part of the board pad high, not rain, prevent rust o8.2. examination. Before the installation of corrugated pipe, to check the appearance to prevent deformation, there are trachoma bellows installed inside the o8.3. seal. The joint of the two bellows joints, to ensure that the length of the joint is not less than 30 cm, the distance between the two ends of the same, sealed with sealing tape joints to prevent leakage of slurry o

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Form Traveler

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords