Food Grade Coating Stucco Embossed Aluminum Freezer Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

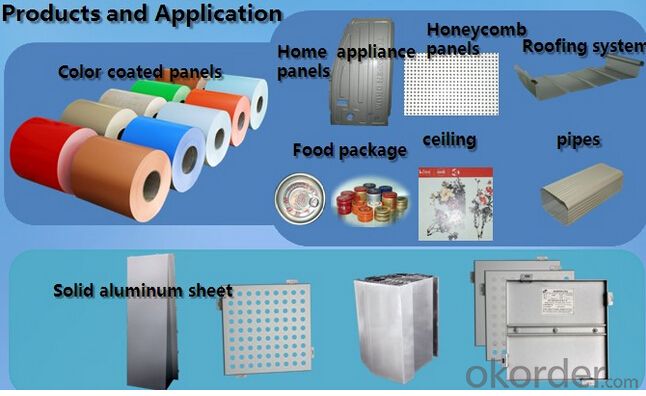

1.Structure of Food Grade Coating Stucco Embossed Aluminum Freezer Sheet Description:

Food Grade Coating Stucco Embossed Aluminum Freezer Sheet is widely used in the strength requirements of the product. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Food Grade Coating Stucco Embossed Aluminum Freezer Sheet:

Aluminum Alloy: 1100 3003 3004 5052 5182

Temper: O-H112

Thickness: 0.15mm---1.5mm

Width: From 18mm---2000mm

3. Food Grade Coating Stucco Embossed Aluminum Freezer Sheet Images:

4. Food Grade Coating Stucco Embossed Aluminum Freezer Sheet Specification:

ALLOY | SEPCIFICATION | TEMPER | |

THICKNESS | WIDTH | ||

1100, 1050,1060,1070 | 1.0-5.0 | 1000-2200 | H114,H112 |

3003,3004,3105 | 1.0-5.0 | 1000-2200 | H114,H112 |

5052,5005,5754,5083 | 1.0-5.0 | 1000-2200 | H114,H112 |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q:Can the aluminum sheets be used for manufacturing ventilation systems?

- Yes, aluminum sheets can be used for manufacturing ventilation systems. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for ventilation systems. Its high thermal conductivity allows for efficient heat transfer, making it ideal for applications where temperature control is necessary. Additionally, aluminum is easily formable, allowing for the creation of complex shapes and designs required for ventilation systems. Overall, aluminum sheets are a popular and practical choice for manufacturing ventilation systems.

- Q:Does anyone know anything about the value of aluminum can(beer, soda, etc.) pull tabs? I have heard a rumor that the tabs are worth more than the cans and that a gallon jug of tabs can be sold at recycling centers for several hundred dollars.Anyone know if this is really true?

- This okorder posting stating tab redemption to be a myth, The type I silver aluminum pull tab (the normal pop can tab which accounts for 96.21% of the U.S. market) weighs in at about 0.65 pounds per thousand (0.0104 ounces each). These tabs have no special value other than the fact that they are scrap aluminum. A gallon of tabs is about 3,400-4,700 tabs (they is no way to get an exact number, as I have recorded 156 different tabs, and there is the matter of the little curly thing which tangles all the tabs together and can affect volume by up to 36%), so a gallon should weigh in close to 2.65 pounds. As scrap aluminum is going for 50 cents to a dollar, depending where you live, yoiu would therefore have a value of $1.33 to $2.65 in metal.

- Q:Aluminum plate 90 degree bending, why cracking?

- Should be the aluminum sheet material and the state of the wrong, I do not know what brand of aluminum plate, with 1060 Aluminum plate, the state: soft 90 degrees bending, not cracking

- Q:Where else besides deodorant can we find aluminum?

- aluminum foil

- Q:Can aluminum sheets be used for solar reflectors?

- Yes, aluminum sheets can be used for solar reflectors. Aluminum is highly reflective and has excellent heat resistance, making it an ideal material for solar reflectors. The reflective surface of aluminum sheets helps to redirect and concentrate sunlight onto solar panels or other solar devices, maximizing their energy efficiency. Additionally, aluminum is lightweight and durable, making it easy to handle and suitable for outdoor applications.

- Q:Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and bent without fracturing or cracking. This property makes aluminum an ideal material for various applications, including the manufacturing of aircraft, automobiles, and household items. The flexibility of aluminum sheets allows for the creation of intricate designs and complex shapes, making it a highly versatile material. However, it is important to note that the thickness and grade of the aluminum sheet can influence its bendability. Thicker sheets may require more force and specialized tools to achieve the desired bend, while softer grades of aluminum may be more easily bent.

- Q:Are the aluminum sheets suitable for automotive applications?

- Indeed, automotive applications can make use of aluminum sheets. Being a lightweight material with a high strength-to-weight ratio, aluminum proves to be an excellent choice for the automotive industry. Its attributes lend themselves well to this industry, offering numerous benefits such as enhanced fuel efficiency, improved handling, and increased performance. Furthermore, aluminum's resistance to corrosion is advantageous for automotive applications, as it contributes to the longevity of vehicles. Furthermore, aluminum sheets possess the ability to be easily shaped and molded into various forms, which grants automotive manufacturing greater design flexibility. In conclusion, the utilization of aluminum sheets in automotive applications has gained popularity due to their myriad advantages and their positive impact on vehicle performance and sustainability.

- Q:Can the aluminum sheets be used for manufacturing heat sinks?

- Aluminum sheets are capable of being utilized in the production of heat sinks. Owing to its exceptional thermal conductivity features, aluminum is a favored option for heat sinks. It possesses lightweight properties, exhibits high electrical conductivity, and can be easily machined, rendering it an ideal substance for dissipating heat from electronic components. The malleability of aluminum sheets permits them to be effortlessly shaped, cut, and molded into the desired heat sink design, facilitating effective heat transfer and dissipation. Furthermore, aluminum is resistant to corrosion, which guarantees the enduring and dependable performance of the heat sink. In summary, aluminum sheets are widely employed in the manufacturing of heat sinks for a variety of applications across industries such as electronics, automotive, and aerospace.

- Q:What are the different types of alloys used for aluminum sheets?

- There are several types of alloys commonly used for aluminum sheets, each with its own unique properties and applications. Some of the most common types include: 1. 1100 alloy: This alloy is pure aluminum with excellent corrosion resistance and good formability. It is often used for general sheet metal work, such as roofing and siding. 2. 3003 alloy: This alloy is similar to 1100 but with added manganese, making it slightly stronger. It is commonly used for applications that require moderate strength and good corrosion resistance, such as packaging and automotive parts. 3. 5052 alloy: This alloy is known for its excellent corrosion resistance, especially in marine environments. It also has good formability and weldability, making it suitable for various applications like fuel tanks, marine components, and architectural panels. 4. 6061 alloy: This alloy is one of the most versatile and widely used aluminum alloys. It offers excellent strength, weldability, and corrosion resistance. 6061 is commonly used in structural applications, such as aircraft parts, bicycle frames, and automotive components. 5. 7075 alloy: This high-strength alloy is often used in aerospace and military applications. It has excellent fatigue resistance and good machinability. 7075 is typically used for aircraft structures, missile parts, and high-stress components. These are just a few examples of the various types of aluminum alloys used for sheets. The specific alloy chosen will depend on the desired properties, such as strength, corrosion resistance, formability, and cost, as well as the intended application.

- Q:Are the aluminum sheets recyclable?

- Yes, aluminum sheets are recyclable.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Food Grade Coating Stucco Embossed Aluminum Freezer Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 100000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords