Flat Bar Sizes Slitting Manufacture Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Flat Bar For Many Sizes is used for manufacturing various types of springs and components, for the suspension mechanism in automobiles or the railways.With the short stress production line that can finish foundry and rolling in one process, we are able to produce dozens type of spring flat steel from 6*40mm to 20*150mm. This product is the best choice for springs and chains for car and agricultrure machine.

Product Description

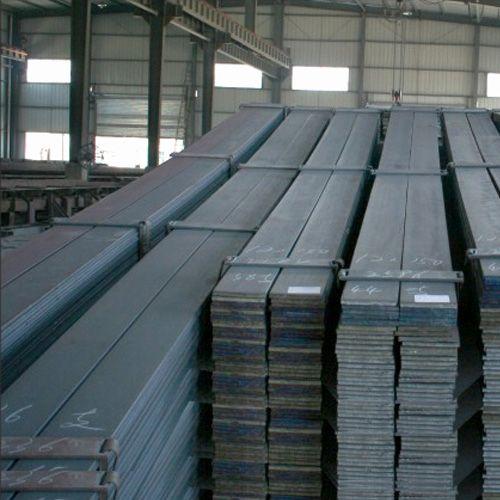

Flat Bar Sizes Slitting Manufacture Steel Flat Bar

steel flat bar grade: A36, S235jr, St37-2, SS400, Q235, Q195

steel flat bar standard: ASTM, AISI, EN, DIN, JIS, GB

steel flat bar thickness:1.5mm-20mm

steel flat bar width: 10mm-1000mm

steel flat bar length: 6m, 9m, 12m or as your requirement.

steel flat bar technique: slitting hot rolled steel coil

Place of origin: Tianjin China (Mainland)

Products Advantages: 1. high quality

2. high dimensional accuracy

3. high utilization rate of material

4. saving cost price

General specification below:

Steel Flat Bar | |||

Width (mm) | Thickness (mm) | Length (m) | Theoretical Weight (kg/m) |

20 | 2.0 | 6/9/12 | 0.31 |

20 | 2.5 | 6/9/12 | 0.39 |

20 | 2.75 | 6/9/12 | 0.43 |

25 | 2.5 | 6/9/12 | 0.49 |

25 | 3.75 | 6/9/12 | 0.74 |

30 | 2.5 | 6/9/12 | 0.59 |

30 | 3.5 | 6/9/12 | 0.82 |

30 | 9.75 | 6/9/12 | 2.30 |

40 | 3.5 | 6/9/12 | 1.10 |

40 | 4.75 | 6/9/12 | 1.50 |

40 | 11.75 | 6/9/12 | 3.69 |

50 | 2.75 | 6/9/12 | 1.08 |

50 | 4.5 | 6/9/12 | 1.77 |

50 | 9.75 | 6/9/12 | 3.83 |

60 | 5.5 | 6/9/12 | 2.60 |

60 | 7.5 | 6/9/12 | 3.53 |

60 | 11.5 | 6/9/12 | 5.42 |

80 | 5.5 | 6/9/12 | 3.45 |

80 | 7.5 | 6/9/12 | 4.71 |

80 | 11.75 | 6/9/12 | 7.38 |

100 | 3.25 | 6/9/12 | 2.55 |

100 | 4.75 | 6/9/12 | 3.73 |

100 | 7.5 | 6/9/12 | 5.89 |

120 | 9.75 | 6/9/12 | 9.18 |

120 | 11.75 | 6/9/12 | 11.07 |

150 | 9.75 | 6/9/12 | 11.48 |

150 | 11.5 | 6/9/12 | 13.54 |

150 | 13.5 | 6/9/12 | 15.90 |

160 | 11.75 | 6/9/12 | 14.76 |

200 | 9.5 | 6/9/12 | 14.92 |

250 | 5.75 | 6/9/12 | 11.28 |

340 | 7.75 | 6/9/12 | 20.68 |

- Q:Can steel flat bars be used for fencing?

- Yes, steel flat bars can be used for fencing. They are commonly used as fence posts or horizontal rails in various types of fencing applications. Steel flat bars are durable, strong, and resistant to weathering, making them suitable for creating sturdy and long-lasting fences.

- Q:Can steel flat bars be used as reinforcement in concrete structures?

- Yes, steel flat bars can be used as reinforcement in concrete structures. Steel bars are commonly used in concrete construction to provide strength and durability to the structure. They are placed within the concrete to resist tensile forces and prevent cracking. Steel flat bars are particularly effective in providing increased flexural strength to the concrete, making them suitable for reinforcing beams, slabs, and other structural elements. The flat shape of the bars allows them to be easily embedded within the concrete, ensuring a strong bond between the two materials. Steel flat bars are available in various sizes and grades, allowing for customization based on the specific requirements of the concrete structure.

- Q:Can steel flat bars be used in food processing industries?

- No, steel flat bars are not typically used in food processing industries as they can corrode over time and contaminate the food. Stainless steel is the preferred material due to its corrosion resistance and hygienic properties.

- Q:What are the applications of steel flat bars?

- Steel flat bars find a wide range of applications in various industries. Construction and structural engineering are among the most common uses. They serve as a structural component in buildings, bridges, and other infrastructure projects, providing strength and stability to withstand heavy loads and forces. The manufacturing industry utilizes steel flat bars in machinery and equipment production. They serve as a base or support for heavy machinery and are used in constructing frames, brackets, and components. The high strength and durability of steel flat bars make them ideal for handling the stress and pressure generated during operation. In the automotive industry, steel flat bars are commonly used in the manufacturing of vehicle frames, chassis, and body panels. Their strength and rigidity ensure the structural integrity of automobiles, contributing to safety and stability. Furthermore, the fabrication industry extensively employs steel flat bars. They are frequently used in fabricating gates, fences, grills, and handrails. The versatility of steel flat bars allows for easy shaping, cutting, and welding, making them an excellent choice for custom fabrication projects. Apart from these industries, steel flat bars have various other applications. They are commonly found in furniture, shelves, and storage racks due to their high load-bearing capacity. Additionally, they are utilized in the production of agricultural equipment like plows and harrows, as well as tools and hardware. In summary, steel flat bars are highly versatile and widely used in construction, manufacturing, automotive, fabrication, and many other industries. Their strength, durability, and versatility make them a popular choice across various applications.

- Q:Are steel flat bars resistant to fire or heat damage?

- Steel flat bars are highly resistant to fire and heat damage. Steel is known for its exceptional fire resistance properties, making it a popular choice for construction and industrial applications. The high melting point of steel, which is around 1370 degrees Celsius (or 2500 degrees Fahrenheit), ensures that it retains its structural integrity and strength even under extreme heat conditions. Additionally, steel does not contribute to the spread of fire, as it does not burn or release combustible gases. Overall, steel flat bars offer excellent protection against fire and heat damage, making them a reliable choice for various industries.

- Q:Can steel flat bars be used for making packaging machinery or equipment?

- Steel flat bars have the capability to be utilized in the production of packaging machinery or equipment. As a robust and long-lasting material, steel can endure the substantial loads and elevated velocities commonly necessary in packaging machinery. The malleability and weldability of steel flat bars allow for the effortless formation and fusion of the essential components and structures required in packaging equipment. Moreover, steel possesses exceptional corrosion resistance, rendering it appropriate for implementation in packaging machinery that may encounter moisture or rigorous environments. In conclusion, steel flat bars present a versatile and dependable option for the manufacturing of packaging machinery or equipment.

- Q:Are steel flat bars suitable for structural support?

- Yes, steel flat bars are suitable for structural support. They are commonly used in construction and engineering projects for their strength, durability, and load-bearing capabilities. Steel flat bars provide structural stability and support in various applications such as beams, columns, braces, and frames.

- Q:What is the maximum length-to-thickness ratio for steel flat bars?

- The maximum length-to-thickness ratio for steel flat bars is typically around 200:1.

- Q:What are the safety precautions when working with steel flat bars?

- When working with steel flat bars, it is important to take certain safety precautions to minimize the risk of accidents or injuries. Some of the key safety measures include wearing personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect against potential hazards. Additionally, using appropriate lifting techniques or mechanical aids to handle heavy or large steel flat bars can prevent strain or back injuries. It is also crucial to ensure a well-ventilated work area to minimize exposure to fumes or dust generated during cutting, grinding, or welding processes. Regularly inspecting the flat bars for any defects or damage and properly securing them during transportation or storage is another important safety practice. Overall, following these safety precautions helps ensure a safer working environment when dealing with steel flat bars.

- Q:Can steel flat bars be used for making handrails?

- Yes, steel flat bars can be used for making handrails. Steel flat bars are strong and durable, making them an ideal material for handrails. They can be easily shaped and welded to create various designs and styles of handrails. Additionally, steel flat bars have a sleek and modern appearance, which can enhance the overall aesthetics of a staircase or walkway. However, it is important to ensure that the steel flat bars meet the necessary safety standards and regulations for handrails in your specific location.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat Bar Sizes Slitting Manufacture Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords