Dust Collector Non woven Fiberglass Dust Filter Bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

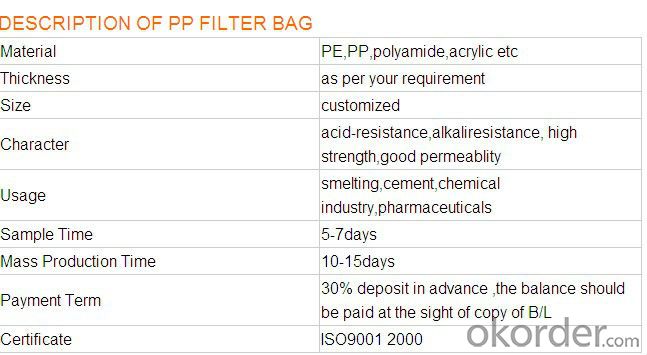

1. Description of Non woven Fiberglass Dust Filter Bag Dust Collector

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton),?Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of Non woven Fiberglass Dust Filter Bag Dust Collector

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of Non woven Fiberglass Dust Filter Bag Dust Collector

Weight(g/m2) | 500~550 | |

Thickness(mm) | 2.3~2.5 | |

Air permeability(m3/ m2/min) | 14~8 | |

Tension at break (N/5×20cm) | Warp | >900 |

Weft | >1200 | |

Elongation at break (%) | Warp | <35< span=""> |

Weft | <50< span=""> | |

Working temperature (℃) | Continuous | 130 |

Instantaneous | 150 | |

Anti-acid | Good | |

Anti-alkali | Common | |

Anti-abrasion | Good | |

Post treatment | Thread burning,surface smoothing or coating etc | |

4. Application fields

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

5. Images of Non woven Fiberglass Dust Filter Bag Dust Collector

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q:What are the advantages of fiberglass filter bags

- The definition of a durable filter is made by using pure, high-quality, blown and blown ultra-fine fiber filter cloth. Filtration accuracy of filter bags is usually given as the accuracy of the nominal filter. The filter bag is a key part of the process of the bag, which is usually hung vertically in the dust collector. The fabric and design of filter bag should strive for efficient filtration, easy dust stripping and durable effect. The characteristics of this section are in the pulse and air box type pulse dust collector, and the dust is attached to the outer surface of the filter bag. Dust and dust are collected in the outer surface of the filter, while the clean gas is filtered through the filter. The inside of the filter bag is used to support the filter bag to prevent the bag from collapsing, and it helps to clear and redistribute the dust cake.

- Q:What is the filter principle of the high performance filter bag?

- The network structure of nanofibers can reduce the thickness and line density of the supporting filter, thus reducing the pressure loss and improving the efficiency of production.

- Q:What are the features and methods of using filter bags?

- The durable filtration bag is made of pure, high quality and high quality blown ultrathin fiber filter. Filter bag has excellent chemical stability and heat resistance performance, is applied to the highest in the performance of the filter material industry representatives, is all common varieties of filter material in the top performance.

- Q:Which is the liquid filter bag?

- It's a liquid filter bag that's been filtered by the dragon, so don't be funny. The worst quality is the hui dragon, the price is dead expensive, the filtration efficiency is bad, the speed of change bag is really fast, too bad, roll thick. The best brand is eton. Your ID lit up.

- Q:How clean is the bag filter bag

- Surface filter mainly adopts nylon monofilament filter bag, metal wire mesh filter bag), the surface of the filter the way for the hole interception, the interception of impurities in the filter material surface, the surface of the filter can be cleaned and secondary use. Remind: liquid filter bag this is a one-time product, under normal circumstances do not recommend repeated use, repeated use of a filter bag filter failure caused easily, at the same time also can cause cross contamination.

- Q:How is the filter material processed by the filter bag?

- Finally is chemical treatment to improve the filter material, especially the dust filtering performance and the strength of glass fiber filter material, heat resistant, flame retardant, corrosion resistant performance, are of great significance.

- Q:The filter bag is very thick and it's hard to wash everybody how to do it

- The original poster hello! Saline and alcohol don't solve the problem. The most reasonable way to eat jackfruit for years is to use peanut oil. If the mucus of jackfruit is in your hand, you will be able to scrub it with a small amount of peanut oil

- Q:How to buy the paint filter bag in the car painting

- The best two come together, so the water can't be in the paint, actually see you use in what place ~ 2 effect should be same Cleaning machine with a wide range of applications in the area of industrial cleaning, car factory should also prepare a few sets of washing machine wash paint, welding slag effect is fairly good, suggest you use force in chengdu feng cleaner, washing machine not only depends on the management and maintenance of late, select a... Again, we have to repair the paint, and I suggest we do it well. According to the coating process of plastic parts, and do not bake, it will be deformed. There is also a choice, which is a good choice. Go to the steam distribution city or paint shop... The cleaning machine has extensive application in the area of industrial cleaning, and the car factory should also prepare several, wash the machine wash the paint, the welding slag effect... Rinse thoroughly. It is suggested that you use the chengdu lifeng cleaning machine, and the cleaning machine should not only look at the management and maintenance of the latter, but choose one...

- Q:What is the filter bag for the washing machine?

- Filtration of all kinds of fine dust that fall on clothing during the laundry process: hair, thread, paper, and other impurities Washing sheets and bedding are the most obvious, and there's a lot of hair that's been collected and useful. Always clean up and don't cause germs.

- Q:Please tell me where the filter bags are sold in the washer.

- The filter bag is broken, the average border is good, and you can make it yourself: you can cut it up and cut it into a bag that is the size of the right size, so you can stick it to the border.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dust Collector Non woven Fiberglass Dust Filter Bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords